APPLICATION

SEARCH by application/use

We introduce unique, high-value products that make use of the materials produced by our group, categorized by application and use in major fields.

We introduce high-value products that support semiconductor manufacturing, categorized by the manufacturing process.

Front-End Process

- Cleaning

- Deposition

- Resist Coating

- Exposure

- Developing

- Etch(for SPE)

- Introduction of Impurities

- Resist Stripping

- Planarization (CMP)

Back-End Process

- Molding

- Grinding

- Wafer Bumping

- Dicing

- Chip Mounting

Front-End ProcessDeposition

As semiconductor devices become highly integrated and miniaturized, sputtering targets are required to have high purity and low particles. Our original manufacturing method provides Si targets for leading-edge semiconductor memory applications that meet these requirements.

Front-End ProcessResist Coating

Taking advantage of the strong acidity and surface tension lowering ability of perfluorinated compounds, we will contribute to the field of semiconductors, especially photoresist materials.

-

EFTOP EF-N441S-30 Bis(nonafluorobutanesulfonyl)imide

Excellent surface tension lowering ability in applications such as surfactants. High solubility in water and organic solvents.

-

EFTOP EF-18 Trifluoromethanesulfonic anhydride

Raw materials for photoacid generators used in photolithography. We can provide high-purity products through integrated manufacturing from raw materials and our proprietary process.

-

EFTOP F-42 PotassiumnNonafluorobutanesulfonate

It is a raw material for photoacid generators used in photolithography. It is characterized by its extremely low hygroscopicity and easy handling.

Front-End ProcessEtch(for SPE)

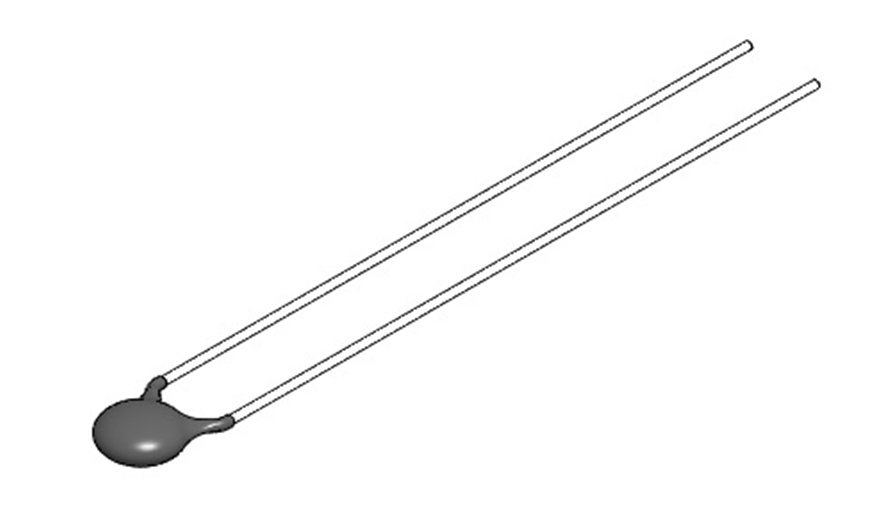

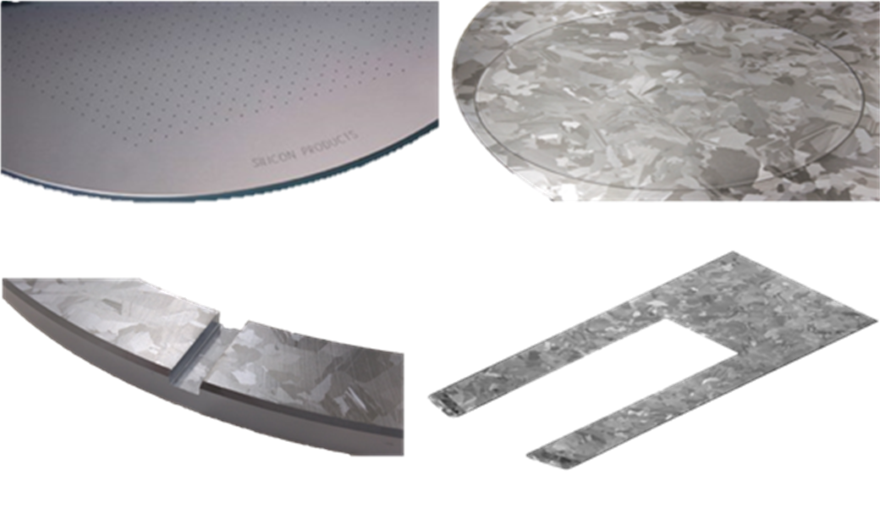

For many years, MMC has developed technologies of manufacturing polycrystalline silicon and silicon wafers for semiconductors. These technologies can provide materials and components that contribute to improving the performance of Semiconductor Production Equipment.

-

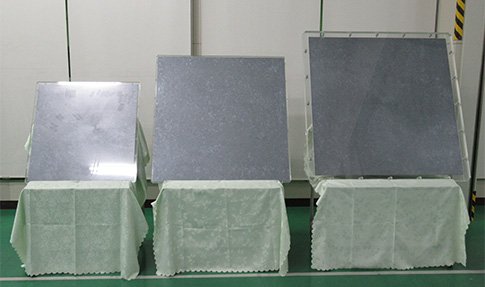

Columnar Crystal Silicon

MMC can provide one of the largest Columnar Crystal Silicon as silicon crystal material in the world.

Available: Rectangular:1200×1200×230H, Cylinder:Φ1200×230H Compared to other silicone materials, it has high mechanical strength (bending strength). -

Precision Silicon Products

Precision Silicon Products as components for Semiconductor Production Equipment without damage layer.

- High-purity Single Crystal Silicon/Columnar Crystal Silicon

- Microfabrication and high cleanliness cleaning are possible.

-

Seal Products

SUNELAST® E Series

Fluoroelastomer with outstanding plasma resistance, low particle generation, and antistatic properties. Complies with various environmental regulations such as PFOA and PFOS free. -

Seal Products

SUNELAST® K Series

Fluoroelastomer with the highest heat-resistant properties. Maintains small compression set and initial vacuum properties even after heated up to high temperatures. -

Seal Products

Silicon Rubber for ultra-low temperature

Excellent plasma resistance performance even in ultra-low temperature such as close to -80℃ environments where other materials cannot be used. -

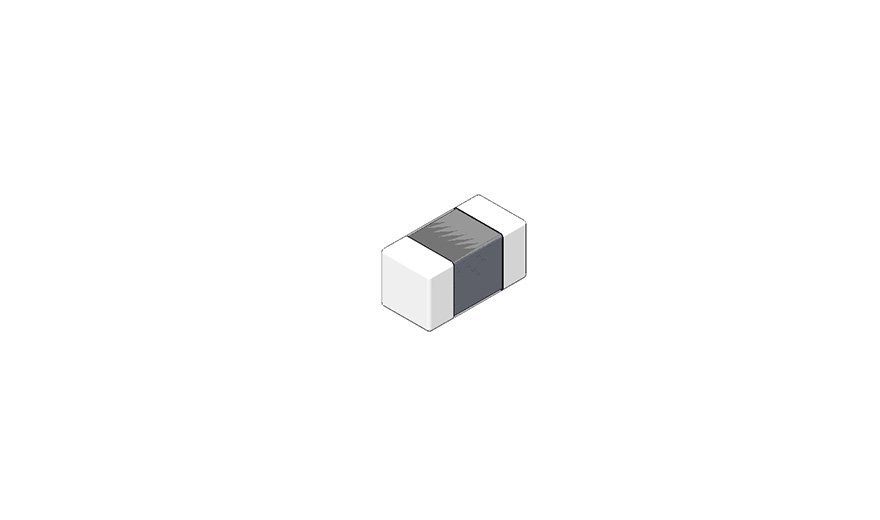

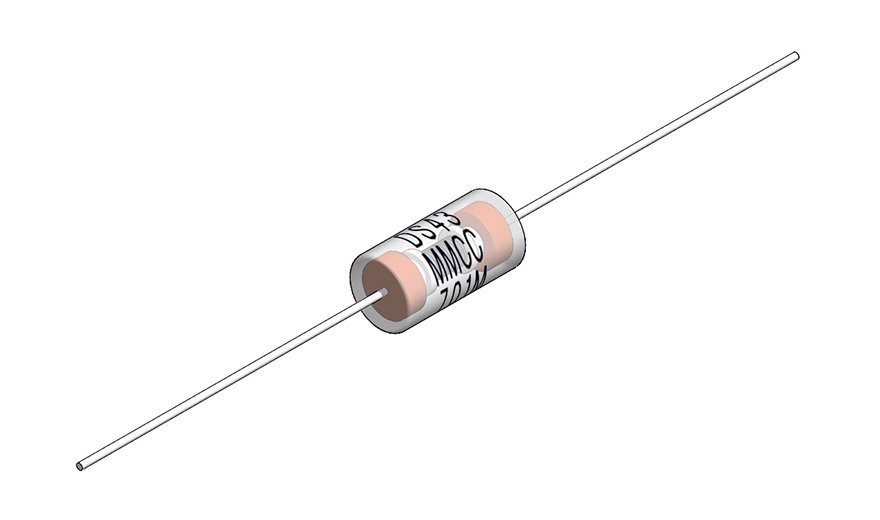

Thermistor TX03 Series

A highly reliable chip thermistor, which uses a unique four-sided glass coating, gives it excellent mechanical strength, high environmental resistance, and migration resistance.

R=±0.5%、B=±0.3%.

Operating temperature range is -40~125℃.

Front-End ProcessIntroduction of Impurities

Our proprietary coating diffuser does not contain chlorine as a raw material, therefore there is no concern about corrosion of equipment such as spin coaters or environmental pollution of clean rooms.

MCD(Mitsubishi Coating Diffusion Source)

A coating diffusion agent containing antimony as an N-type dopant. For silicon semiconductor wafers, used for embedding and diffusion in bipolar ICs, Bi-CMOS, etc.

Back-End ProcessWafer Bumping

With the demand increasing for smaller semiconductor packages, flip chip packages became the mainstream, but flip chip packages are especially sensitive to "Soft Errors," errors in IC memory data caused by radiation such as cosmic ray and alpha particles which are emitted from the semiconductor materials and the environment.

-

Plating Solution

High quality and high performance Low Alpha solder plating solutions for bump formation to meet the needs of leading-edge packaging technologies for semiconductors, which are becoming smaller and denser.

-

Anode

Made of the same Low Alpha material as the plating solution for replenishing the metal components. We can customize the shape and specifications depending on the various types of plating equipment.

We introduce high-value products that contribute to the evolution of xEV, categorized by application and automobile parts.

Battery

Our thermistors enable accurate thermal management that helps ensure safety by preventing battery overheating and ignition.

-

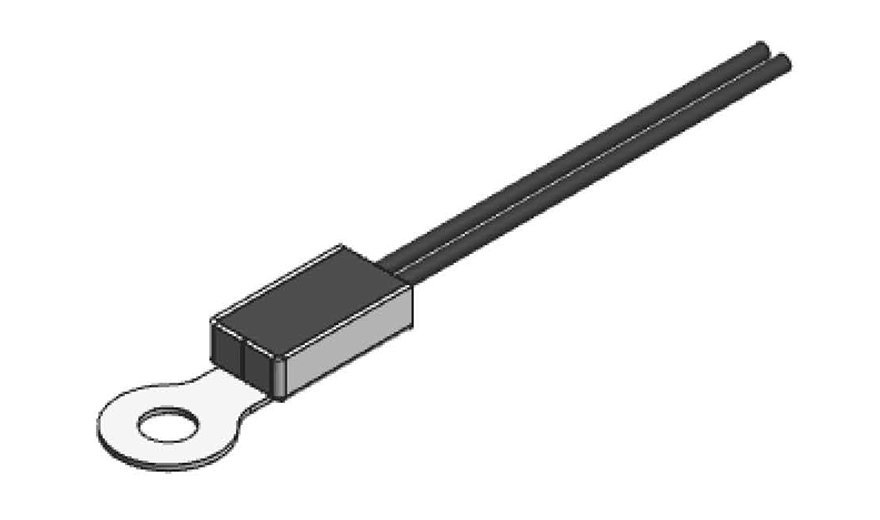

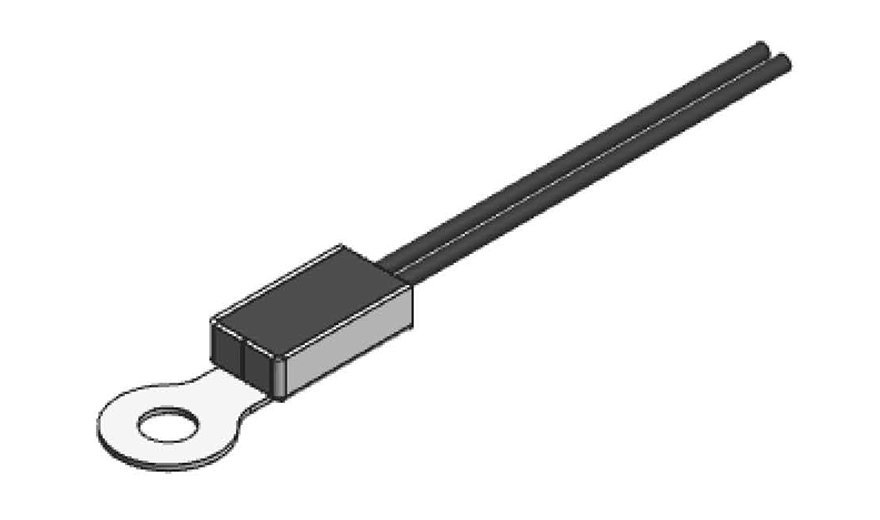

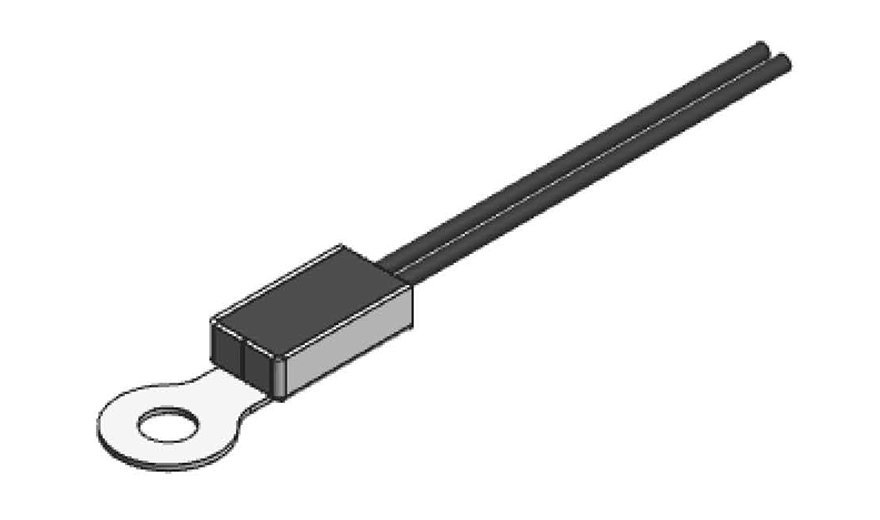

Thermistor

RD18 SeriesResin-coated sensor eliminates the risk of shorting leads within the sensor holder, thereby reducing man-hours in the insulation process.

Its heat resistance reaches 150℃. -

Thermistor Sensor

STS-74 SeriesUltra thin surface temperature sensor with a small but precise chip thermistor integrated in FPC.

The distance between the measurement target and the element is tight, enabling fast response.

Motor

A sensor of high heat resistance and high-precision, maximizing the performance of motors that generate heat due to large currents.

Inverter

Next-generation power semiconductor devices such as SiC require highly reliable bonding material with excellent temperature monitoring and heat dissipation to control the heat generated by high current.

MMC contributes to the high performance of power semiconductors through high heat-resistant and high-precision thermistors and AuSn paste, a Pb-free material.

-

Gold-tin (AuSn) Alloy Solder Paste

AuSn alloy, which has a high melting point (280°C), is made into a paste to achieve highly reliable bonding. We offer a variety of application methods to meet your needs.

-

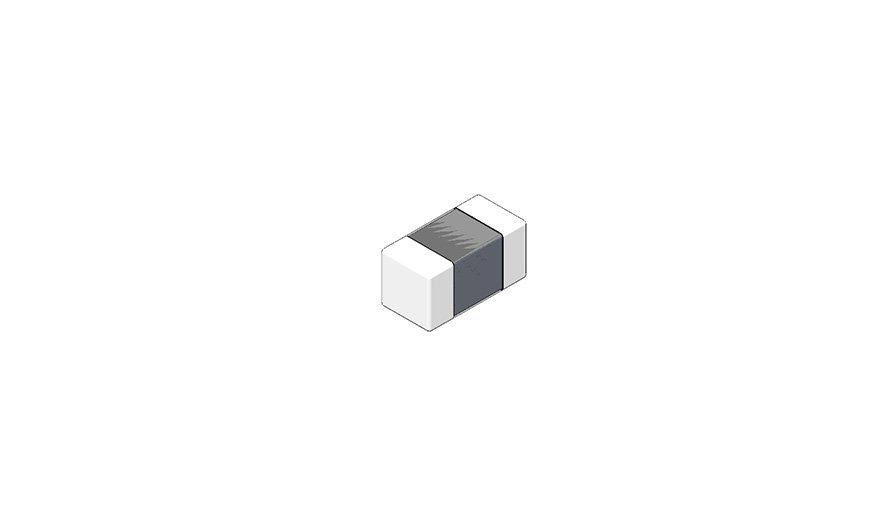

Thermistor

TK05 SeriesA highly reliable chip thermistor, which uses a unique four-sided glass coating, gives it excellent mechanical strength, high environmental resistance, and migration resistance.

R=±1%、B=±1%

Operating temperature range is -40~175℃. -

Thermistor

PA30 SeriesGlass-encapsulated thermistors for Al wire bonding.

Compatible with solder and sintered Ag fixation. The insulation between the front and back surfaces provides freedom of placement. -

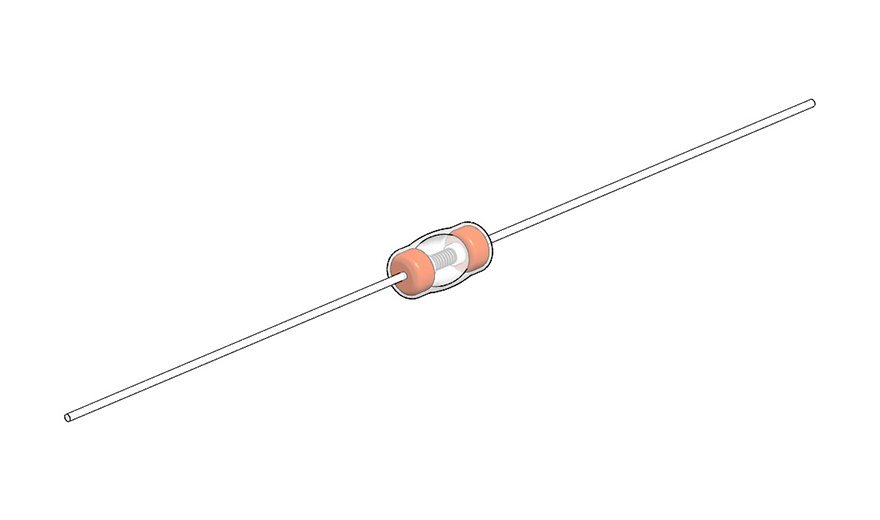

Thermistor

MH18 SeriesGlass molded MELF style onboard thermistor.

Suitable for high temperature applications and excellent choice for harsh environments. -

Thermistor Sensor

STS-74 SeriesUltra thin surface temperature sensor with a small but precise chip thermistor integrated in FPC.

The distance between the measurement target and the element is tight, enabling fast response.

OBC(Onboard Charger)

Measuring temperature with our high-precision thermistor enables stable and safe charging. We also provide lightning surge solutions that are compatible with next-generation high-output fast charging standards (NACS, CHAdeMO, GBT, CCS) and regular chargers (various AC withstanding voltage tests).

-

Thermistor

RD18 SeriesResin-coated sensor eliminates the risk of shorting leads within the sensor holder, thereby reducing man-hours in the insulation process.

Its heat resistance reaches 150℃. -

Thermistor

TZ05 SeriesA highly reliable chip thermistor, which uses a unique four-sided glass coating, gives it excellent mechanical strength, high environmental resistance, and migration resistance.

R=±0.5%、B=±0.3%.

Operating temperature range :-40~150℃. -

Thermistor Sensor

STS-74 SeriesUltra thin surface temperature sensor with a small but precise chip thermistor integrated in FPC.

The distance between the measurement target and the element is tight, enabling fast response. -

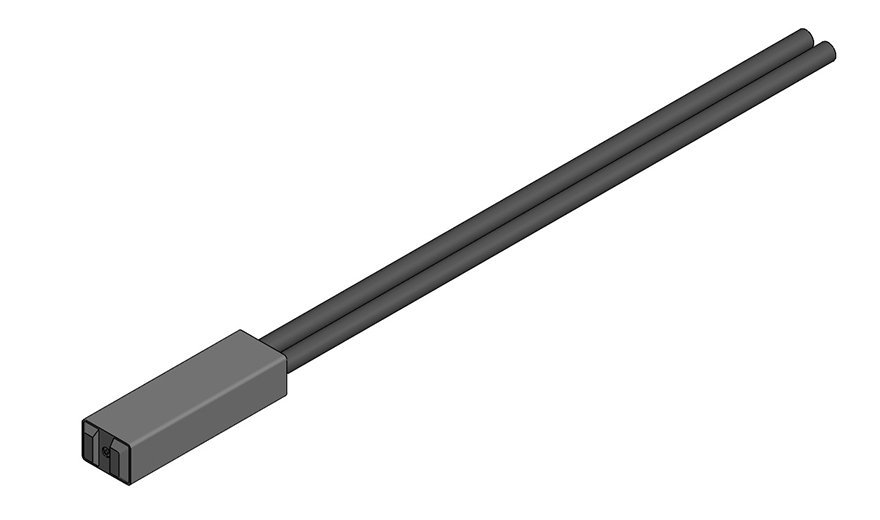

Thermistor Sensor

PPS caseResin encased temperature sensor that is small, and has high withstand voltage and high heat resistance (up to 200℃)

Customizable shape and size according to installation method. -

Surge Absorber

DA53 SeriesEffective for surge countermeasures between lines, line-ground.

It has excellent surge response and is stable against repeated surges. -

Surge Absorber

DE37 SeriesEffective as a surge countermeasure for resonance countermeasures.

The size is compact(φ3.7mm L7.0mm) and easy to mount. -

Surge Absorber

CSA70 SeriesEffective as a surge countermeasure against resonance.

It is a SMD type surge absorber.

Size: L 4.0mm W 3.2 mm T 2.3mm.

Oil/Coolant Temperature

Protect various components by precisely measuring the temperature of the coolant, which is essential for vehicle heat management.

-

Thermistor

GR15 SeriesGlass-molded radial leaded type thermistors.

Suitable for high temperature applications. It can be used with automatic insertion equipment. -

Thermistor

RD18 SeriesResin-coated sensor eliminates the risk of shorting leads within the sensor holder, thereby reducing man-hours in the insulation process.

Its heat resistance reaches 150℃. -

Thermistor Sensor

Oil Temperature Sensor (Metal case)Integrated waterproof connector sensor that can be affixed using a fasten screw.

Durable at high temperature(sensor portion 200℃).

Double molding makes for airtight construction. -

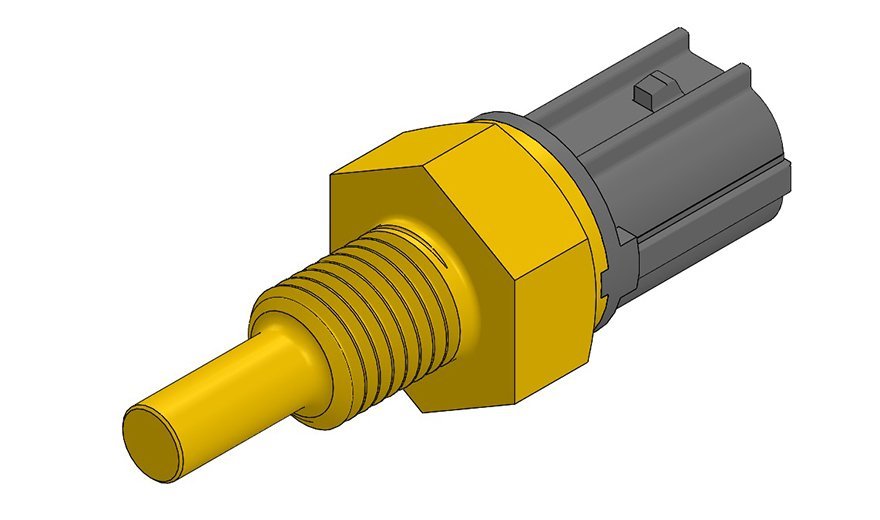

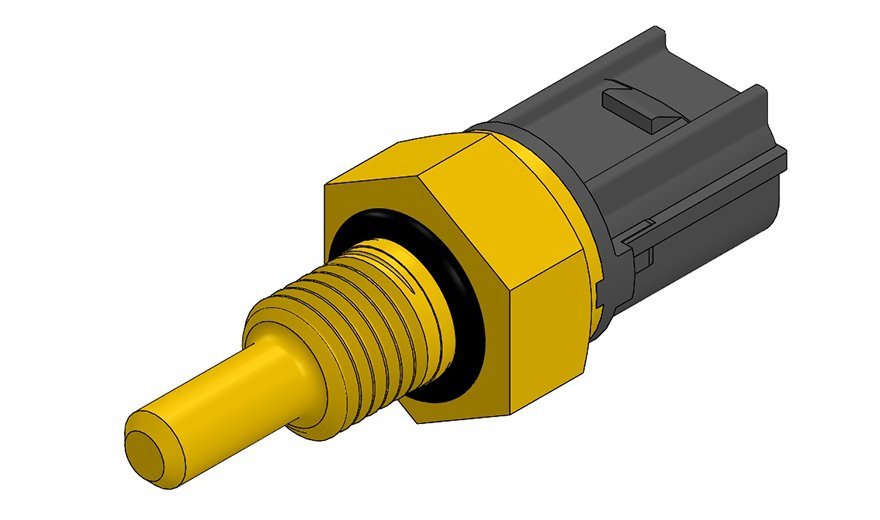

Thermistor Sensor

Coolant Temperature Sensor (Metal case)Integrated waterproof connector sensor with O-ring that can be affixed with screws.

Durable at high temperature.

Double molding makes for airtight construction. -

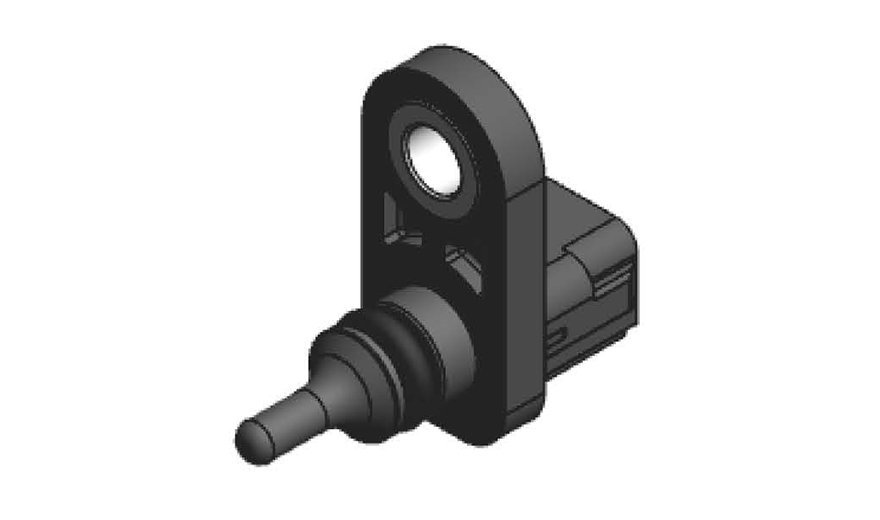

Thermistor Sensor

Oil Temperature Sensor (Resin case)Integrated waterproof connector sensor that can be affixed with screws.

Durable at high temperatures(sensor portion 200℃)

Double molding makes for airtight construction. -

Thermistor Sensor

Coolant Temperature Sensor (Resin case)Integrated waterproof connector sensor with O-ring that can be affixed with screws.

Durable at high temperature. (sensor portion 130℃)

Double molding makes for airtight construction.

DC/DC Converter

Protect semiconductors by detecting heat generated by voltage conversion with high precision.

-

Thermistor

TD05 SeriesA highly reliable chip thermistor, which uses a unique four-sided glass coating, gives it excellent mechanical strength, high environmental resistance, and migration resistance.

R=±1%、B=±1%.

Operating temperature range is -40~150℃. -

Thermistor Sensor

STS-74 SeriesUltra thin surface temperature sensor with a small but precise chip thermistor integrated in FPC.

The distance between the measurement target and the element is tight, enabling fast response.

ECU

Protect ECUs, the brains of automobiles through highly accurate temperature control.

-

Thermistor

GH13 SeriesGlass-molded axial leaded type thermistors.

Suitable for high temperature applications.

It can be used with automatic insertion equipment. -

Thermistor

TZ05 SeriesA highly reliable chip thermistor, which uses a unique four-sided glass coating, gives it excellent mechanical strength, high environmental resistance, and migration resistance.

R=±0.5%、B=±0.3%.

Operating temperature range :-40~150℃. -

Thermistor Sensor

STS-74 SeriesUltra thin surface temperature sensor with a small but precise chip thermistor integrated in FPC.

The distance between the measurement target and the element is tight, enabling fast response.

Air Conditioner

Air conditioning control with high-precision temperature measurement helps to create a comfortable interior space.

LED Headlight

LEDs have a reduced life span when operated in a high temperature environment.

By using high heat-dissipating bonding materials and by monitoring the temperature with a thermistor to derate the LED current, help to reduce LED overheating and extend the life of the LEDs.

-

Gold-tin (AuSn) Alloy Solder Paste

This solder material makes it possible to create high-strength and high thermal conductivity bonding layers and has a high market share of the automotive LED mounting market, including headlamp applications.

-

Thermistor

VH02 SeriesSmall precision type.

Solder:Au/Sn(79/21)Preform.

Excellent compatibility with Au/Sn soldering process.

It maintains long term accuracy and is capable of high temp. soldering. -

Thermistor

TD05 SeriesA highly reliable chip thermistor, which uses a unique four-sided glass coating, gives it excellent mechanical strength, high environmental resistance, and migration resistance.

R=±1%、B=±1%.

Operating temperature range is -40~150℃.

LiDAR

The wavelength of the laser used in LiDAR systems shifts depending on the ambient temperature. Therefore, laser diode temperature is monitored by a thermistor and controlled by a TEC (thermoelectric cooler).

IVI (In-Vehicle Infotainment)

Featuring our very own micro-gap system, our gas discharge tube type surge absorbers have excellent surge protection characteristics and low capacitance that won’t impede the high-speed communication system.

-

Surge Absorber

CSA30 SeriesCSA30 Series(3.2x1.6mm) confirm with IEC61000-4-2(150pF-330Ω-25kV) standard.

-

Surge Absorber

CSA20 SeriesCSA20 Series(2.0x1.25mm) confirm with IEC61000-4-2(150pF-330Ω-25kV) standard.

-

Sarge Absorber

DSP SeriesDSP Series(φ2.6㎜, L 7.0㎜) is 1500pF-0Ω-10kV require.

It is easy to handle because of the size.

Car Window Glass

ITO (Indium Tin Oxide) particles absorb and shield the heat-ray (near infrared ray) of the sunlight, contributing to the measures against heat in automobile cabins and energy saving measures for air conditioners.

Charger Station/ Battery Charger

Our high-precision thermistor monitor and protect the charger from the heat generated from high voltage and high current.

We also have a lineup of surge absorbers compatible with various DC charging voltages such as NACS, CHAdeMO, GBT, CCS and standard charger(AC withstand voltage tests).

-

Thermistor Sensor

PPS caseResin encased temperature sensor that is small, and has high withstand voltage and high heat resistance (up to 200℃)

Customizable shape and size according to installation method. -

Surge Absorber

DA53 SeriesEffective for surge countermeasures between lines, line-ground.

It has excellent surge response and is stable against repeated surges. -

Surge Absorber

DE37 SeriesEffective for resonance countermeasures.

It is compact in size (φ3.7mm L7.0mm) and easy to mount. -

Surge Absorber

CSA70 SeriesEffective for resonance countermeasures.

It is an SMD type surge absorber.

Size: L 4.0mm W 3.2 mm T 2.3mm.