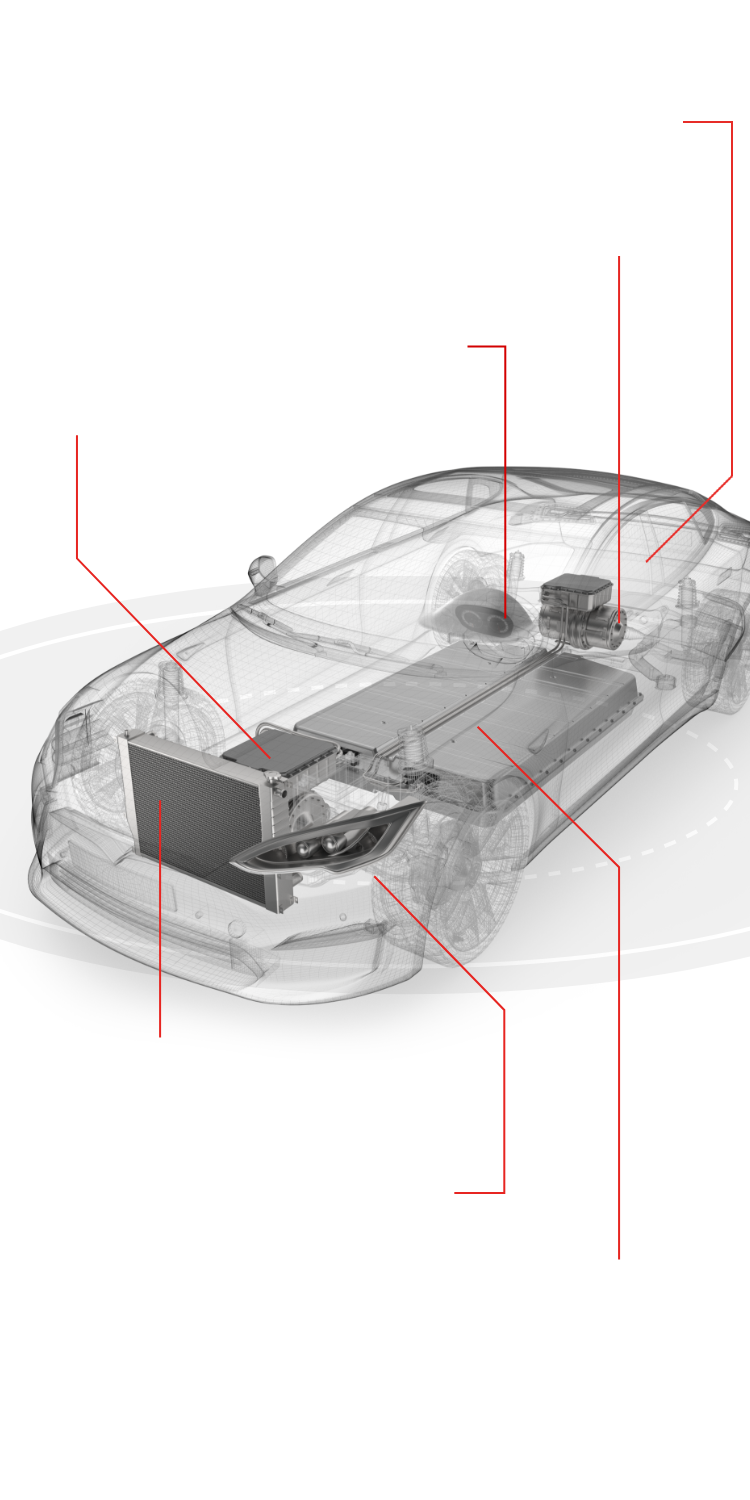

For engineers developing EV technology

Control the heatThermal management solution

by Mitsubishi Materials

-

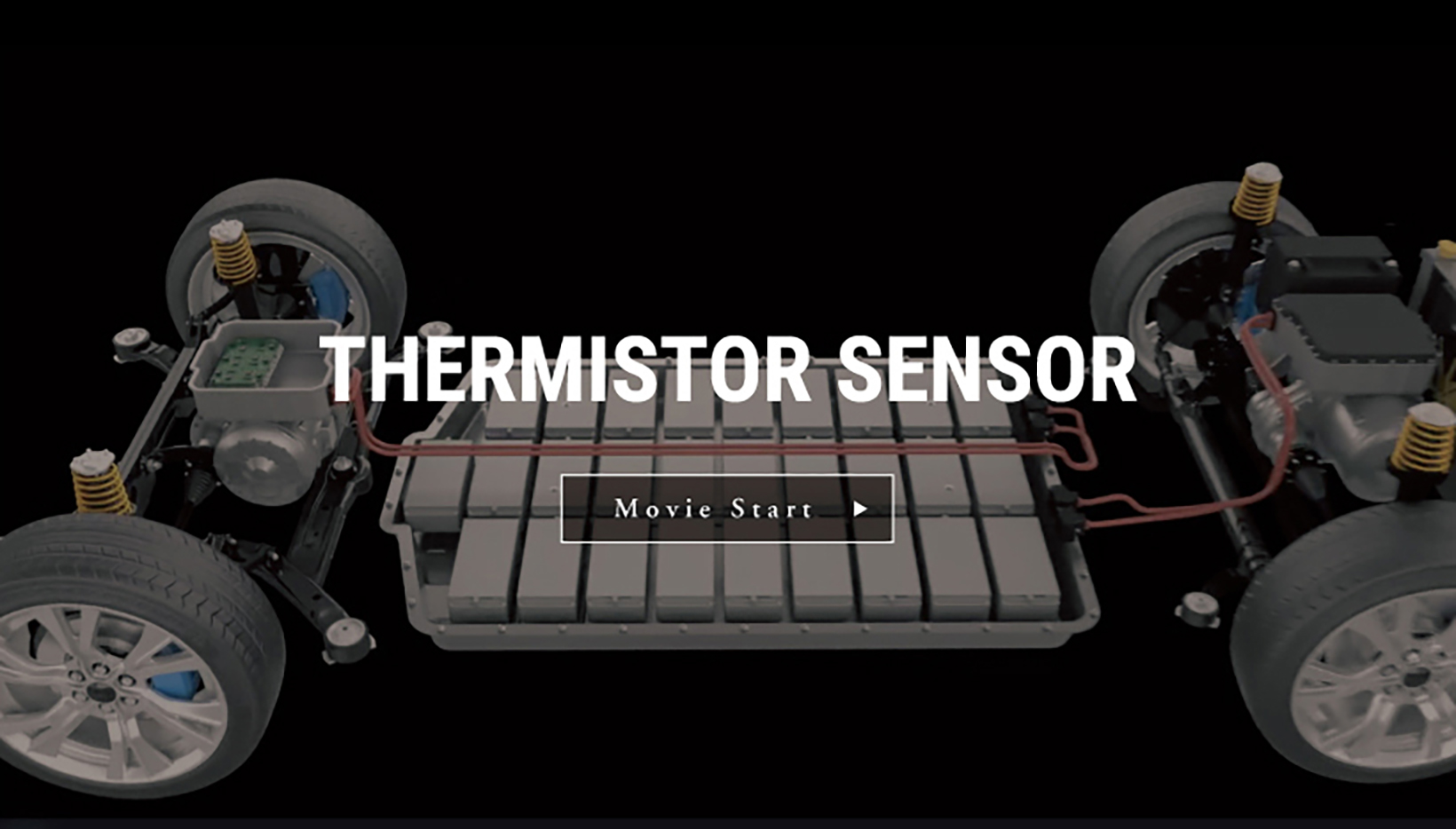

THERMISTOR

SENSOR -

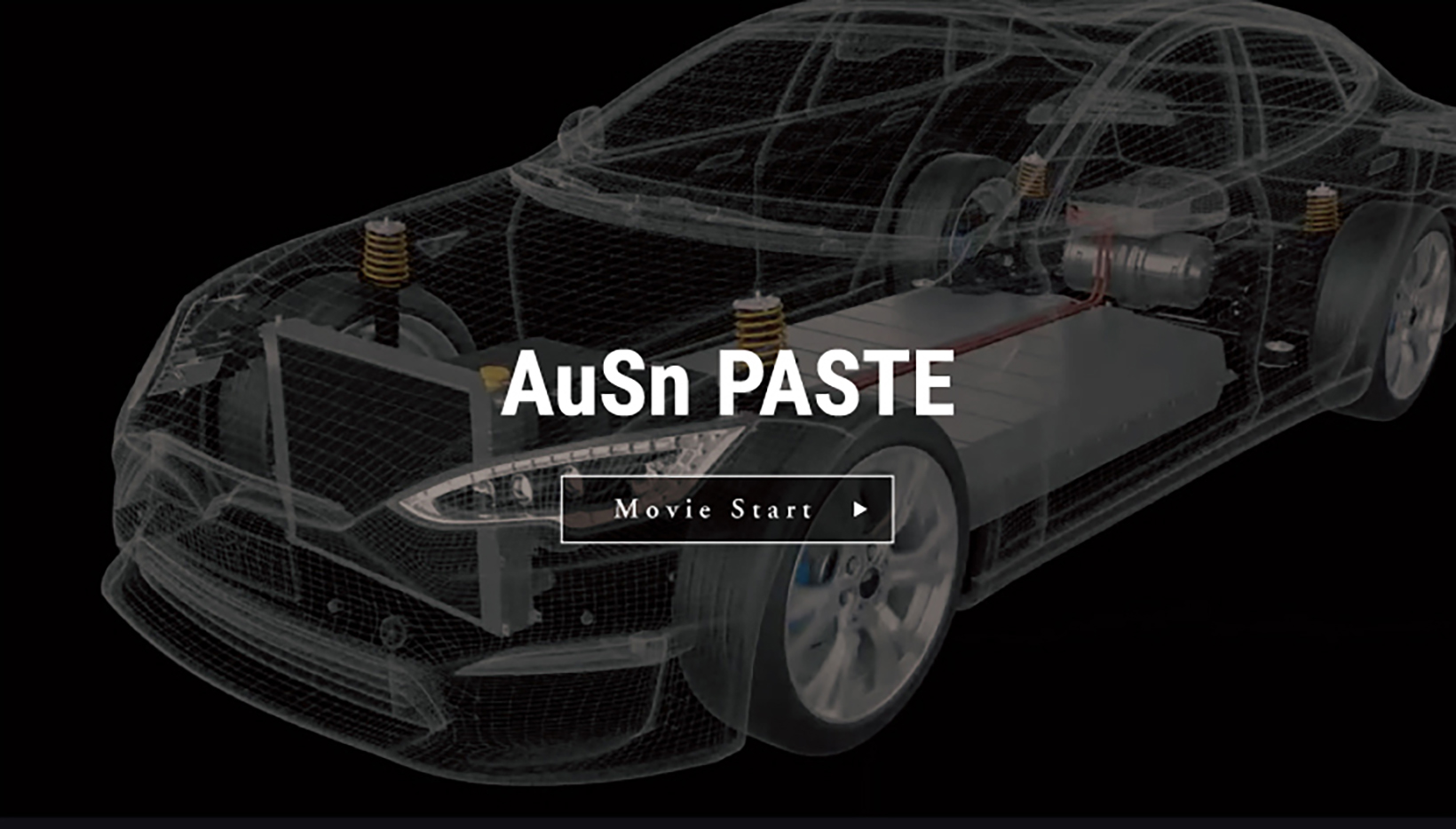

AuSn PASTE

-

SOLAR HEAT-RAY

SHIELDING -

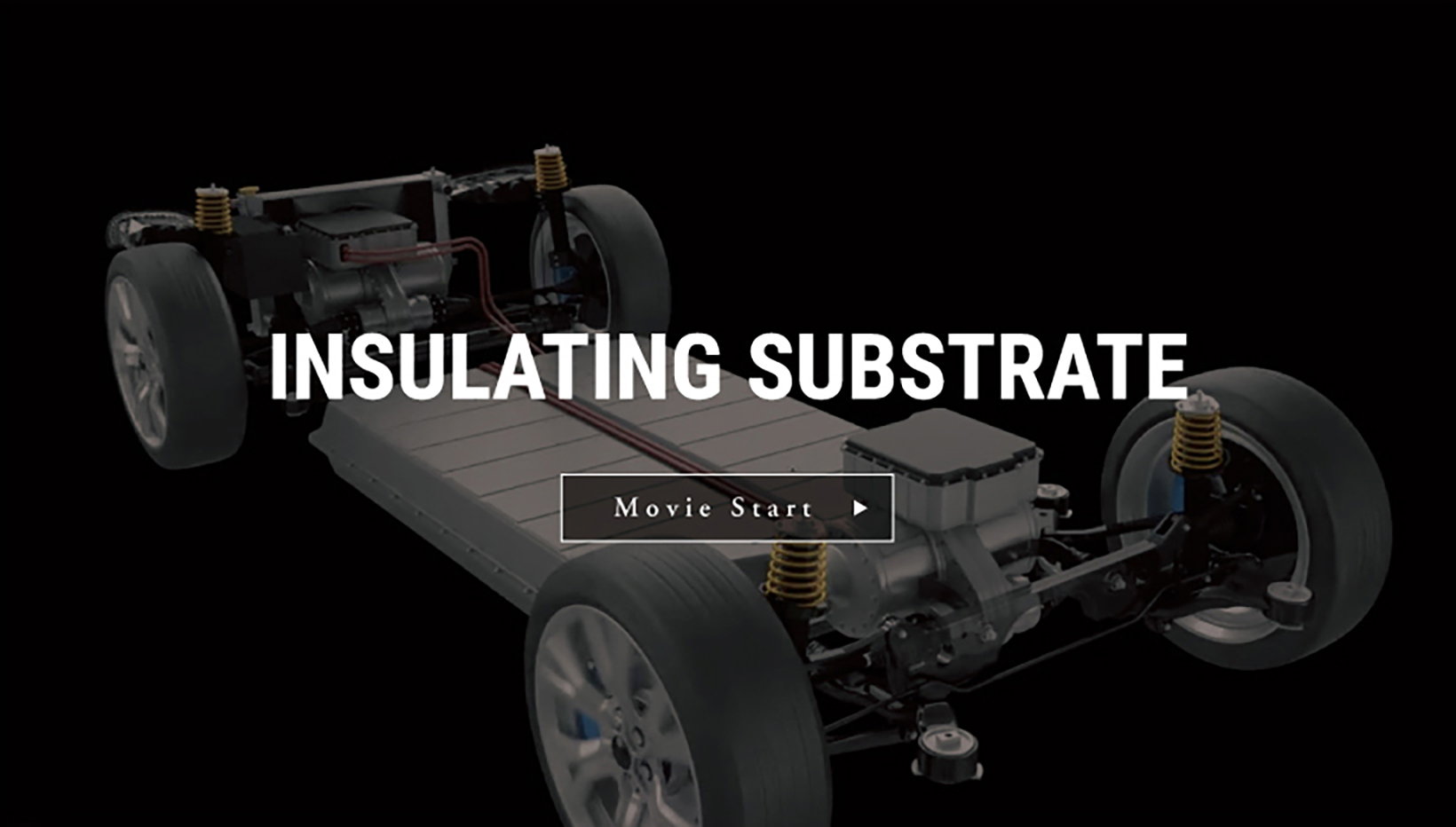

INSULATING

SUBSTRATE

Mitsubishi MaterialsThermal management solution

-

SOLUTION

Battery, Inverter,

Exterior LED, etc.THERMISTOR

SENSORHigh heat resistance, high accuracy,

high-speed response

temperature sensor for various

applications -

SOLUTION

Exterior LED / Interior LEDAuSn PASTE

Boasts a high market share as high

temperature solder with high

reliability for

automotive LED -

SOLUTION

Window, RoofSOLAR HEAT-RAY

SHIELDINGThermal insulation paint with high

transparency by original ITO

micronization and dispersion

technology -

SOLUTION

Drive inverterINSULATING

SUBSTRATEContributes to relieve the thermal

stress and improvement of heat

dissipation with our unique

bonding technology

ABOUT

We can help with your

thermal management needs.

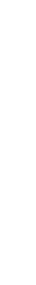

The development of next-generation vehicles is

accelerating around the world.

Under such circumstances,

thermal management of each part

has become crucial. Here at Mitsubishi Materials,

our “controlling the heat” thermal management

solutions

can help you along the way.

SEARCH

Search solutions by parts

Click to check solutions

Click to check solutions

MOTOR

INSTRUMENT PANEL

INVERTER

AIR CONDITIONING

LAMP

BATTERY

WINDOW, ROOF

INSTRUMENT PANEL

- Hope to flexibly change the thickness and shape of AuSn

- Bond strength is not stable due to substrate roughness

- The chip is misaligned when bonding

- Hope to reduce the cost of the cleaning process

- There are problems when using paste in mass production

- Hope to suppress deterioration due to LED heat

- Hope to discuss the structure and shape of the sensor

INVERTER

- Hope to reduce the thermal resistance of the power module

- Hope to improve reliability of the power module

- Hope to realize an efficient cooling structure

- Want a heat-resistant product compatible with SiC power semiconductors

- Hope to measure sudden temperature changes with good response

- Hope to discuss the structure and shape of the sensor

LAMP

Headlamp / RCL / DRL / Fog lamp / Position lamp

/Stop lamp / Direction lamp / Mirror lamp

- Hope to flexibly change the thickness and shape of AuSn

- Bond strength is not stable due to substrate roughness

- The chip is misaligned when bonding

- Hope to reduce the cost of the cleaning process

- There are problems when using paste in mass production

- Hope to suppress deterioration due to LED heat

- Hope to discuss the structure and shape of the sensor

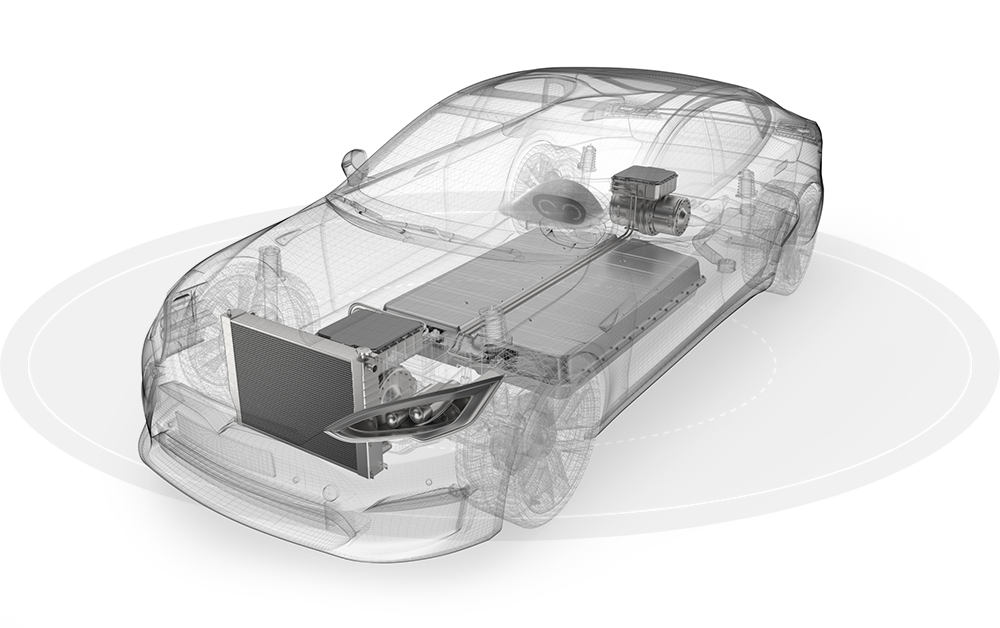

THERMISTOR SENSOR

Do you face these challenges?

Overview

What is a Thermistor Sensor?

In xEVs, components are required to be smaller, lighter, more reliable and have higher output.

Therefore, heat management has become more severe and more important than conventional gasoline-powered vehicles.

Our thermistor sensors have an ultra-fast thermal response and extremely high accuracy, enabling improved thermal management, and detecting abnormalities quickly.

AuSn PASTE

Do you face these challenges?

Overview

What is AuSn paste?

In recent years, high-brightness LEDs have been widely used as the light source for automobile headlamps.

However, when LEDs become brighter, heat dissipation and ensuring reliability becomes a major issue.

Mitsubishi Materials’ AuSn paste is a AuSn eutectic solder that is ideal for mounting high-brightness LEDs, and because of its high strength and thermal conductivity, it is a bonding material that boasts a high market share in the mounting of LEDs for headlamps.

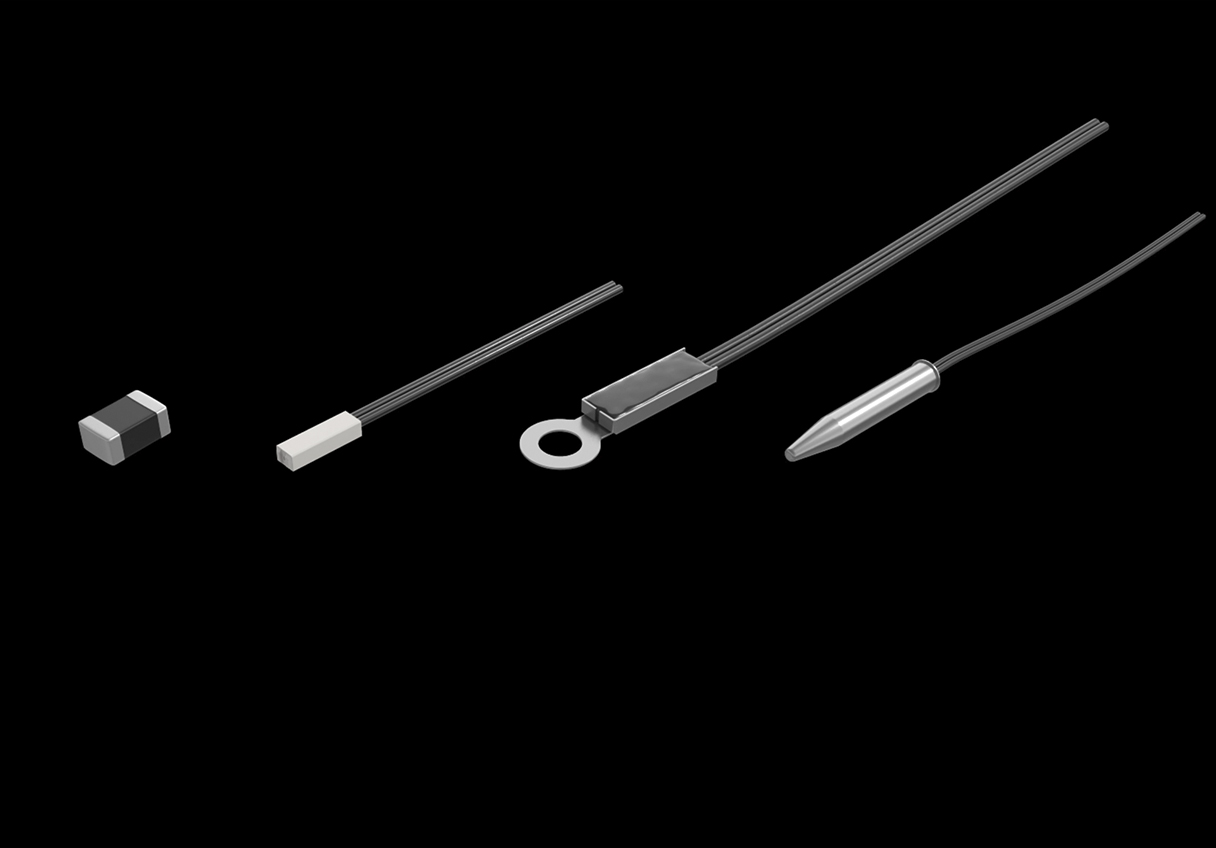

SOLAR HEAT-RAY SHIELDING

Do you face these challenges ?

Overview

What is Solar Heat-ray Shielding (ITO) ?

A large amount of sunlight and heat rays (near-infrared rays), which cause an increase in the temperature inside the car, enter through the windows and roof of the car. As a result, people in the car feel uncomfortably hot, and the downside is that power consumption increases as the cooling load increases. Mitsubishi Materials' "heat-ray cutting material (ITO)" solves this problem by applying nano-sized ITO particles to windows and roofs. By absorbing and cutting the heat rays (near-infrared rays) contained in sunlight, it contributes to measures against heat in the car and energy-saving measures for air conditioners.

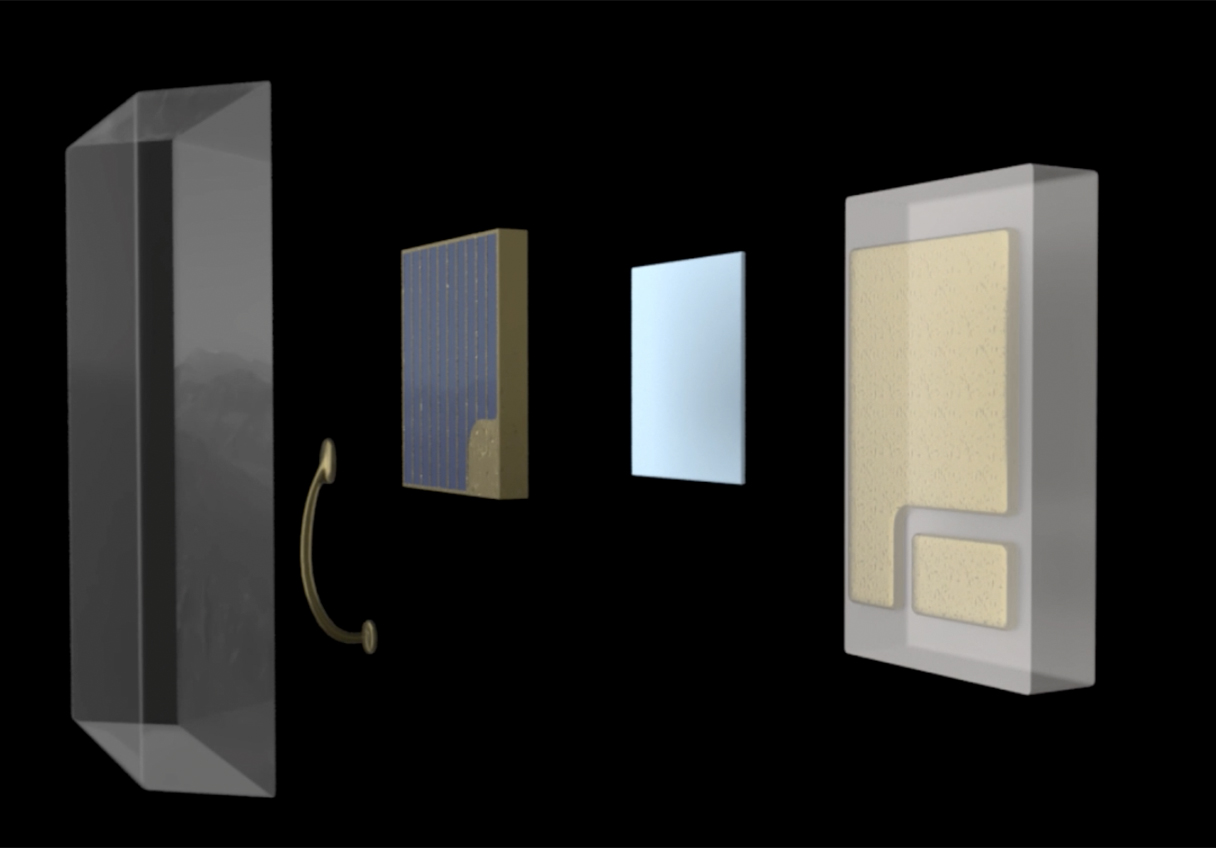

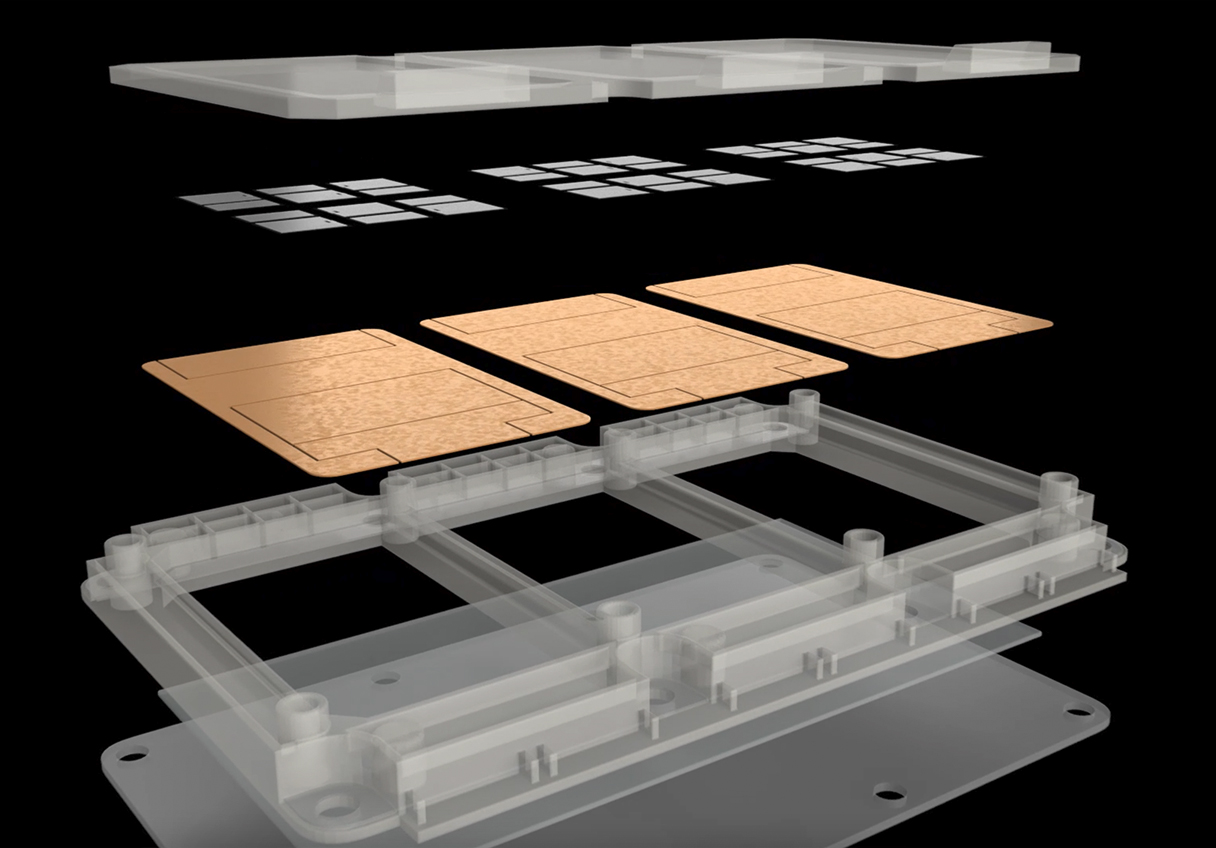

INSULATING SUBSTRATE

Do you face these challenges ?

Overview

What is DBA®︎ substrate for power module ?

Driving inverters of xEVs in recent years have adopted high-performance power modules.

Insulated heat-dissipating boards that mount power semiconductors in power modules are required to have both reliability to withstand harsh cold heat cycles and heat dissipation to quickly dissipate heat.

Mitsubishi Materials’ DBA®︎ substrate has a track record of being used in a cumulative total of approximately 10 million xEVs because it can maintain bonding quality even in harsh environments with severe temperature changes due to its unique bonding technology.

( Responsible Dept.: Monozukuri and R&D Strategy Dept. )

DBA® and DBAC® are registered trademarks of Mitsubishi Materials Corporation in Japan.