THERMISTOR SENSOR

Solution

Proposal of optimal

temperature sensor

Challenge

Hope to discuss the structure and shape of the sensor

- Looking to measure the temperature accurately.

- Do not know what thermistor should be used.

- Do not know if the thermistor currently in use is the most optimal.

- Please make a proposal that includes the mounting method and installation method.

Solution Overview

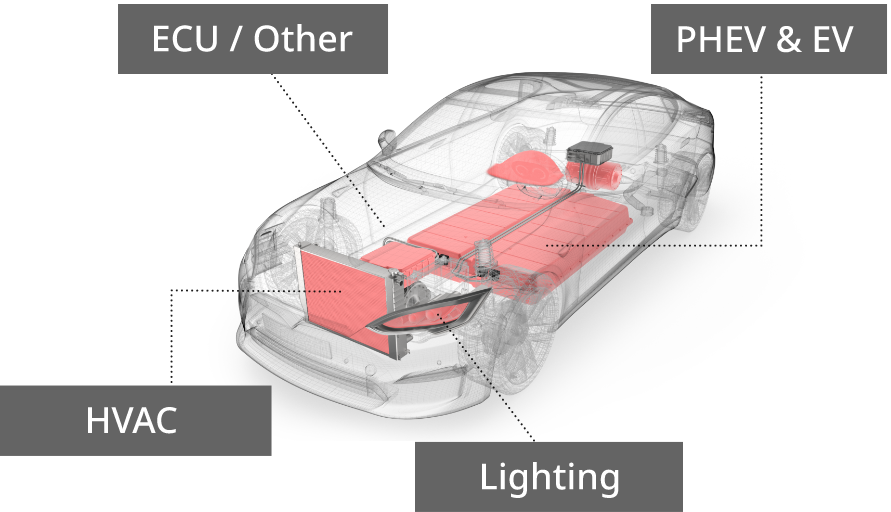

Adopted in a wide variety of products by making full use of core technology

Making full use of ceramic material design technology, resin material design technology, thermistor sensor design technology, and reliability evaluation technology, we have a track record of adopting various thermistors for air conditioning system applications, LED headlight applications, xEV / in-vehicle applications.

ECU / Other

- Power steering

- PCB / Flex temp

- Cooling fan

PHEV & EV

- Inverter

- DC-DC converter

- Motor

- Battery pack

- OBC

- Thermal reactor

- Electric pump

HVAC

- Evaporator

(Fin / Air)

- Ambient

- Interior

Lighting

- HID / LED / DRL

Thermistor

Sensor

CORE TECHNOLOGY

Ceramics material

design technology

- XRD analysis

- SEM-EDS analysis

- Particle size distribution measurement

- Surface area measurement

Thermistor sensor

design technology

- Transmissive X-ray

- X-ray CT structure analysis

- Heat conduction analysis

- Stress analysis

Resin material

design technology

- FT-IR analysis

- TG-DTA、DSC、TMA analysis

- Rheometer measurement technology

- Karl Fischer moisture meter measurement technology

Long-term accuracy

evaluation technology

- High temperature environment

- High temp, high humidity environment

- Low temperature environment

- Thermal shock testing (in air / liquid)

- Vibration test (〜20G)

- Various strength testers

Effect

-

Before

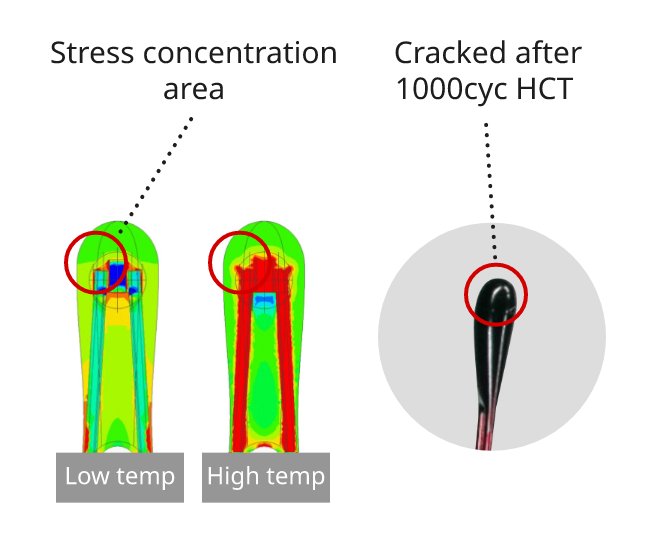

After the temperature cycle test, the sensor resin cracked. The stress simulation revealed that the stress was concentrated due to the mismatch of the resin materials.

-

After

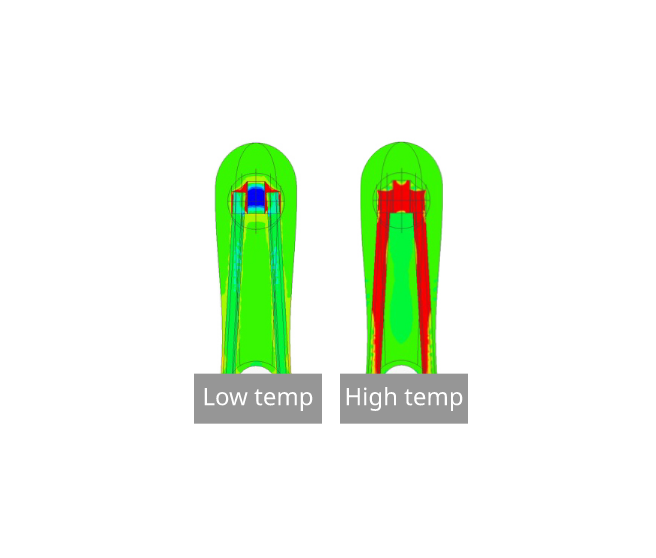

By changing the resin material, it is verified by simulation that the stress is relieved, and a highly reliable sensor design is achieved.

ADVANTAGE

-

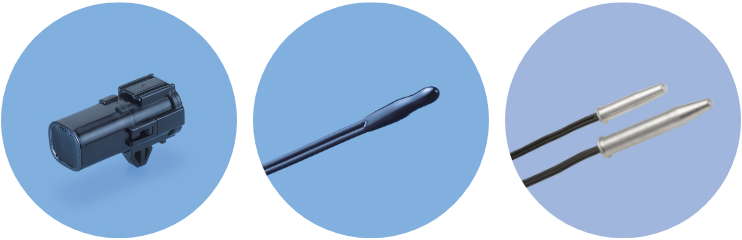

ADVANTAGE01

We offer a wide range of sensors for various applications and provide you with the optimal sensor solution.

-

ADVANTAGE02

Utilizing analysis equipment and technology unique to material manufacturers, we develop and offer thermistor element materials that meet the needs of our customers.

-

ADVANTAGE03

We have a track record of supplying many in-vehicle sensors to our customers. We also support a wide variety of reliability tests.

OTHER SOLUTIONS

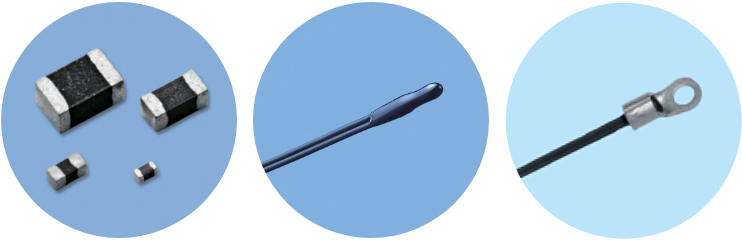

Other solutions for thermistor sensor

-

THERMISTOR SENSOR

Hope to suppress deterioration due to LED heat

-

THERMISTOR SENSOR

Want a heat-resistant product compatible with SiC power semiconductors

-

THERMISTOR SENSOR

Hope to measure sudden temperature changes with good response

Other related solutions

This solution utilizes

Mitsubishi Materials' thermistor sensor.