News

APPLICATION

SEARCH by application/use

PRODUCTS

Products Lineup

Products

We introduce unique, high-value products that make use of the materials produced by our group.

- Precision Silicon Products

- Gold-tin (AuSn) Alloy Solder Paste

- Sol-Gel Solutions

- Low Alpha Solders

- NTC Thermistors

- Thermistor Sensors

- Surge Absorbers

- Columnar Crystal Silicon

- Perfluoroalkylsulfonyl Compounds

- Transparent Conductive Materials

- White Electro-conductive Materials

- Insulation Black Pigment

- Solar Heat-ray Shielding

- Seal Products

PICK UP

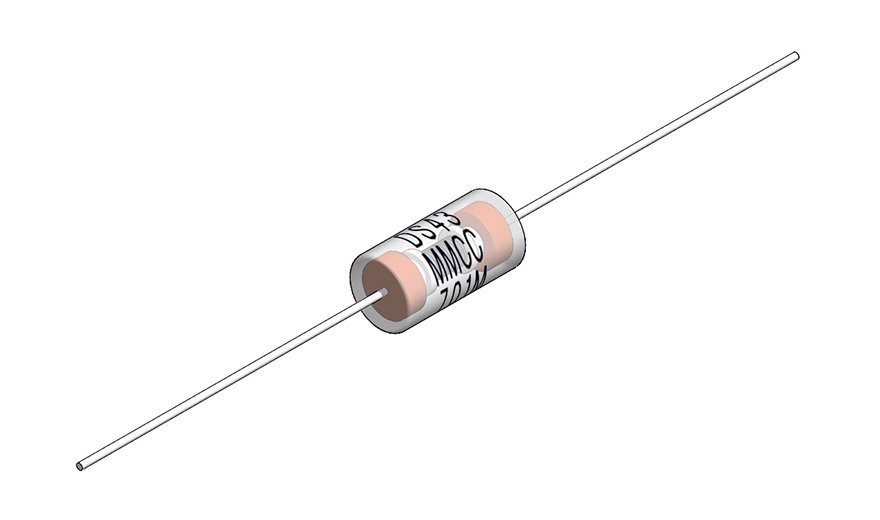

DA53 Series

The DA53 Series has a micro-gap cut to an accuracy of several tens of microns for rapid response against induced lightning and electrostatic discharges.Ideal for protecting power supplies from power-line surge voltage.

Gold-tin (AuSn) Alloy Solder Paste

Mitsubishi Materials' Gold-tin(AuSn) alloy paste offers high process flexibility.

New KH05 Series

The KH Series are wire-bondable flake style NTC Thermistors

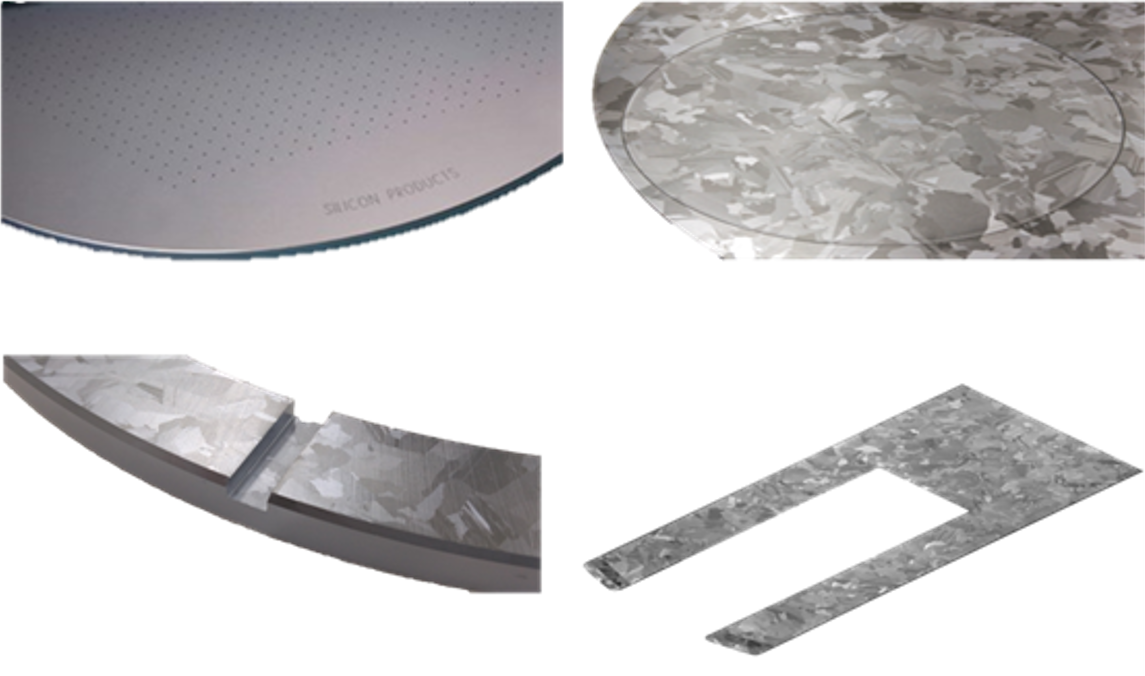

Precision Silicon Products

We manufacture internal parts primarily for semiconductor front-end processing equipment from crystalline silicon ingots. Please consider our high-purity silicon processed products as reduction of metal contamination on wafers, particle countermeasures, heat-resistant parts, and chemical-resistant parts.

SOLUTION

SOLUTIONS / KNOWLEDGE

Solution

We have useful information like usage examples, technical information, and explanations for using our products.

- Thermal Management Solution for Mobility

- Characteristics of Gold-Tin Alloy Paste

- Characteristics of Low Alpha Plating Chemicals

- Basic Characteristics of NTC Thermistors

- Example of Using NTC Thermistors

- Chip Thermistor Resistance Simulator

- Basic Characteristics of Surge Absorbers

- Surge Absorber Examples

- Surge Countermeasures