AuSn PASTE

Solution

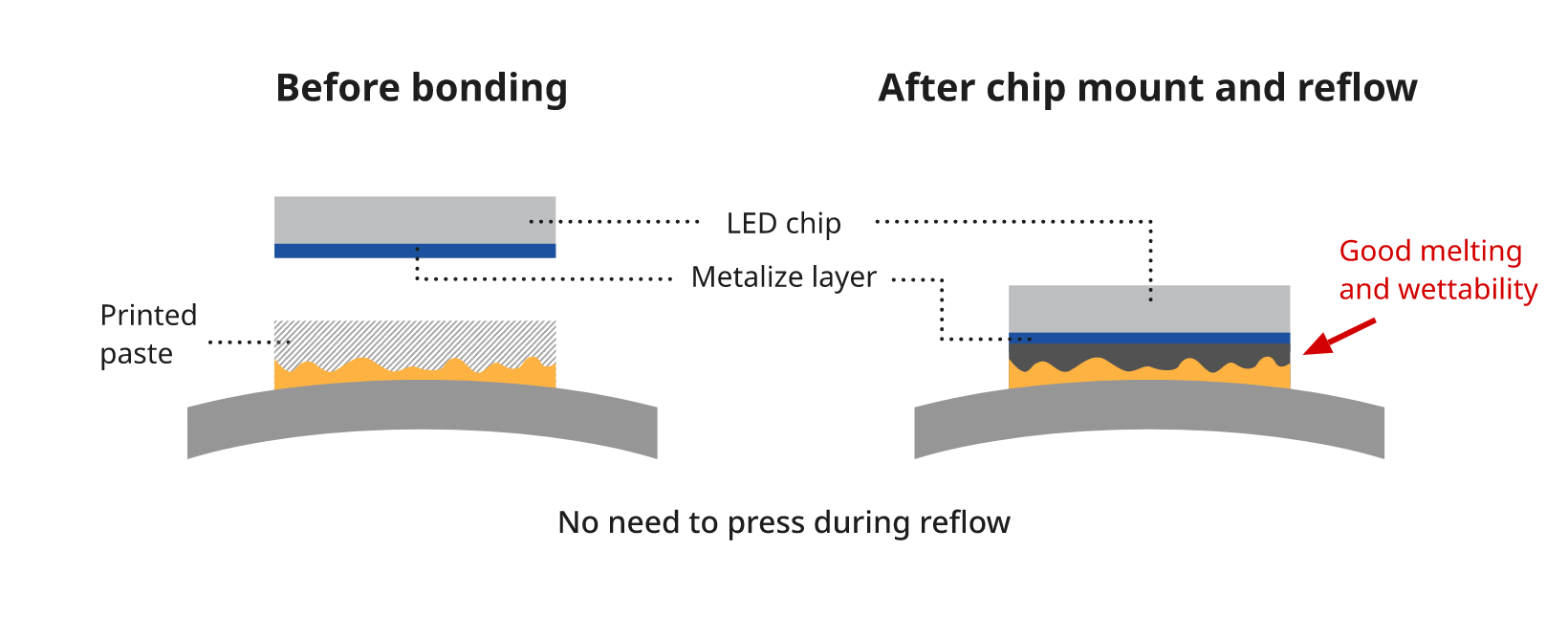

Chips can be bonded to rough

or warped substrates

Challenge

Bond strength is not stable due to substrate roughness

- When a chip with a AuSn deposition film is bonded, the surface of the substrate is rough and does not attach properly.

- When a chip with a AuSn deposition film is bonded, the warp of the substrate is large and does not attach properly.

Solution Overview

AuSn paste is a solder paste that is a mixture of AuSn powder and flux. In addition to flexibility in the supplying shape, since it contains a flux that accelerates the wetting and spreading of the solder, it can fill into the uneven parts of the substrate and get wet, and good bonding can be obtained.

Effect

-

Before

When a chip with a AuSn deposition film is used, since the surface of the substrate is rough / the substrate is greatly warped, the part where the AuSn layer is not in contact remains unwetted even after reflow.

-

After

Even if the substrate has surface roughness and / or warpage, the fill into the parts where the distance between the substrate and the chip are uneven, thus good bonding can be obtained.

MOVIE

This video shows a comparison between the bonding of chips with AuSn deposition film, and AuSn paste. AuSn paste ensures good bonding conditions and bonding strength.

ADVANTAGE

-

ADVANTAGE01

Since it is a paste, it can flexibly handle unevenness on the substrate.

-

ADVANTAGE02

The AuSn paste can also flexibly handle the warpage of substrates that are difficult to bond with AuSn deposition films.

OTHER SOLUTIONS

Other solutions for AuSn paste

-

AuSn PASTE

Hope to flexibly change the thickness and shape of AuSn

-

AuSn PASTE

The chip is misaligned when bonding

-

AuSn PASTE

Hope to reduce the cost of the cleaning process

-

AuSn PASTE

There are problems when using paste in mass production

Other related solutions

This solution utilizes

Mitsubishi Materials' AuSn paste.