AuSn PASTE

Solution

Self-Alignment

Challenge

The chip is misaligned when bonding

- AThe chip is mounted using AuSn eutectic preform, but the misalignment at the time of chip mounting is directly linked to the misalignment after reflow.

- When the chip with AuSn deposition film is bonded, the mounting speed (throughput) of the mounter cannot be increased because high position accuracy is required at the time of mounting.

Solution Overview

When using AuSn eutectic preform or a chip with AuSn thin-film deposition film in AuSn junction, high mounting accuracy is required at the time of mounting, so the operating speed of the mounter cannot be increased, and the throughput reaches a plateau.

Our AuSn is a paste type and contains an active flux, so it has excellent fluidity when melted. If the electrode shapes on the substrate side and the chip side match, the effect of automatically aligning the positions and orientations can be obtained by the surface tension of the molten metal, which is called the “self-alignment effect”. As a result, the mounting accuracy required is reduced, and the mounting throughput can be improved.

■ Case study

-

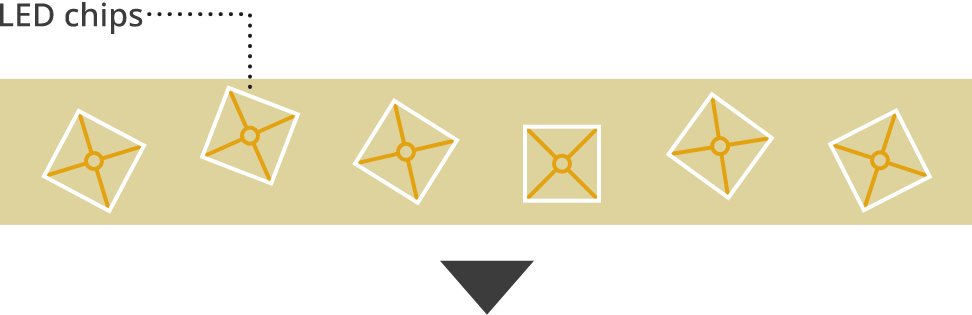

When LED is set

(before reflow)

-

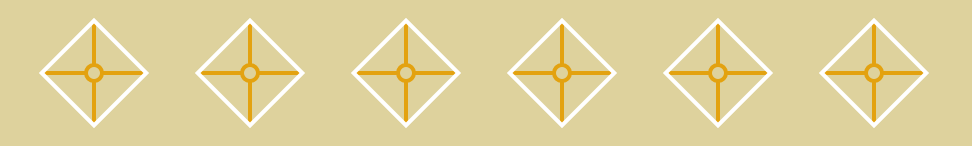

LEDs aligned by

self-alignment

(after reflow)

Effect

-

Before

When using a chip with an AuSn thin-film deposition film, high mounting accuracy is required at the time of mounting, so the operating speed of the mounter cannot be increased, and the throughput reaches a plateau.

-

After

Since AuSn paste has high fluidity during reflow, it is easy to obtain the ”self-alignment effect”, an effect of automatically aligning the position and orientation by the surface tension of the molten solder if the substrate and chip electrode shapes are matched. Therefore, the mounting accuracy required is reduced, and faster chip mounting is possible, and throughput can be improved.

MOVIE

This video shows the moment the AuSn solder melts, the surface tension of the molten solder moves the chip onto the pad.

ADVANTAGE

-

ADVANTAGE01

Some misalignment of the chip mount is corrected by self-alignment effect.

-

ADVANTAGE02

High-speed chip mounting is possible and throughput is improved.

OTHER SOLUTIONS

Other solutions for AuSn paste

-

AuSn PASTE

Hope to flexibly change the thickness and shape of AuSn

-

AuSn PASTE

Bond strength is not stable due to substrate roughness

-

AuSn PASTE

Hope to reduce the cost of the cleaning process

-

AuSn PASTE

There are problems when using paste in mass production

Other related solutions

This solution utilizes

Mitsubishi Materials' AuSn paste.