INSULATING SUBSTRATE

Solution

Proposal of simulation-optimized

structure.

Challenge

Hope to reduce the thermal resistance of the power module

- Hope to improve heat dissipation performance of power module.

- Hope to reduce number of mounting dies on power module.

Solution Overview

Commonly, insulating substrate for automobile invertor is composed of double side copper circuit ceramic substrate (AMB substrate, DCB substrate) bonded with heat sink, aim to improve heat dissipation.

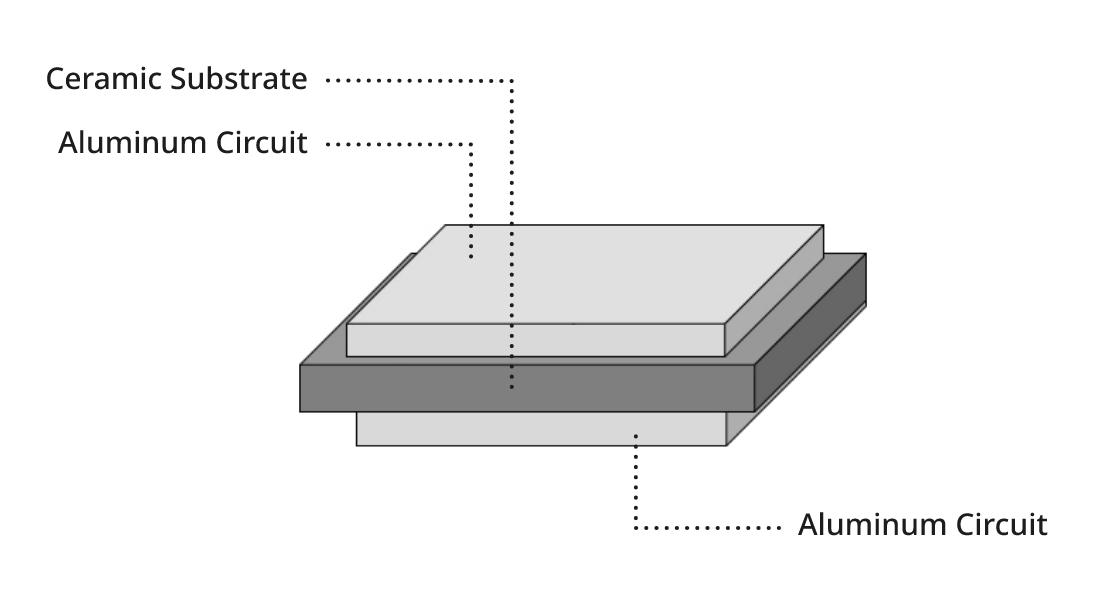

We have high heat dissipation power electric insulating substrate (DBA® Substrate) which has double side high purity (4N) aluminum circuit.

Our DBA® Substrate was adopted by the first practicalize HEV (Hybrid Electronic Vehicle) in the world, which is extremely high reliable power electric insulating substrate. We applied our original core technology to the bonding process of pure aluminum and ceramic (aluminum nitride). Therefore, bonding performance will not change and keep quite high reliable bonding characteristic even under the severe temperature changing condition.

Demand of reducing heat resistance, we could consult for how to change design of insulating substrate and heat sink.

We could also propose how to reduce heat resistance with the use of our thermal simulation technology in order to optimize specification.

Effect

-

Before

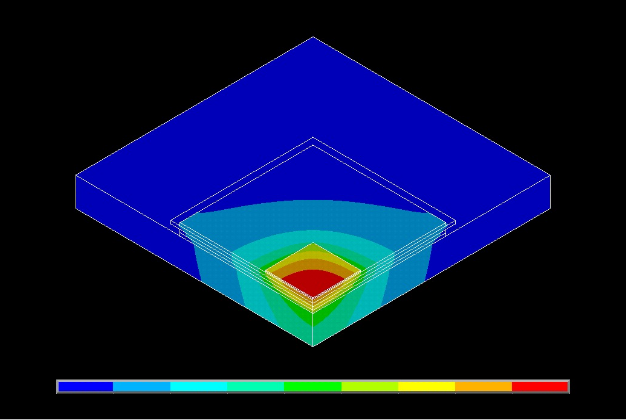

Hope to reduce the number of mounting dies and heat resistance with insulating substrate bonded with heat sink, but heat resistance will increase and hard to design.

Heat release value 100W Si□10-t0.1/SAC-t0.1 DCB□30(Cu-t0.3/SiN-t0.32/Cu-t0.3) SAC-t0.3 Base□50(Cu-t3.0) Coefficient of heat transfer 20,000 -

After

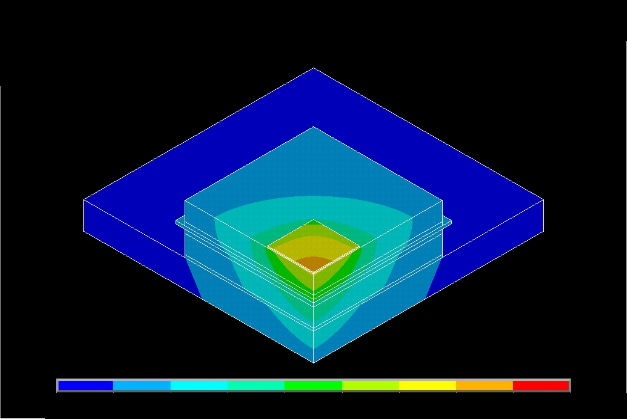

Realizing lower heat resistance by changing design of insulating substrate and heat sink.

Heat release value 100W Si□10-t0.1/SAC-t0.1 DBAC®□30(Cu-t2.0/Al-t0.4/SiN-t0.32/Al-t0.4/Cu-t2.0) SAC-t0.3 Base□50(Cu-t3.0) Coefficient of heat transfer 20,000

ADVANTAGE

-

ADVANTAGE01

Enable to reduce the number of mounting dies by improvement of heat dissipation.

-

ADVANTAGE02

Realizing high performance module by improvement of heat dissipation.

-

ADVANTAGE03

Lead to module minimization and weight saving by improvement of heat dissipation.

OTHER SOLUTIONS

Other solutions for insulating substrate

-

INSULATING SUBSTRATE

Hope to improve reliability of the power module

-

INSULATING SUBSTRATE

Hope to realize an efficient cooling structure

Other related solutions

-

AuSn PASTE

Hope to flexibly change the thickness and shape of AuSn

-

THERMISTOR SENSOR

Want a heat-resistant product compatible with SiC power semiconductors

-

THERMISTOR SENSOR

Hope to measure sudden temperature changes with good response

-

THERMISTOR SENSOR

Hope to discuss the structure and shape of the sensor

This solution utilizes

Mitsubishi Materials' insulating substrate.

( Responsible Dept.: Monozukuri and R&D Strategy Dept.)