AuSn PASTE

Solution

The thickness and shape of

AuSn joint material can be

changed flexibly

Challenge

Hope to flexibly change the thickness and shape of AuSn

- When forming a AuSn thin deposition film on a chip, the material usage efficiency during film formation is poor and expensive.

- When the electrode shape of the chip with AuSn deposition film is changed for each product type, it is necessary to manufacture a jig (exposure mask, etc.) for each product, which increases the cost and difficulty to manage.

Solution Overview

AuSn paste is a solder paste that is a mixture of AuSn powder and flux. AuSn alloys of any shape and thickness can be formed by applying and reflowing using the printing, dispensing, and pin transfer methods.

Effect

-

Before

The unit price for chips with AuSn deposition film is very high.

-

After

Since the shape and supplying thickness of the paste can be freely changed, the shape and thickness of the chip electrode can be changed simply by replacing the printing mask or modifying the program of the dispensing device.

-

Before

If the electrode shape is different for each type of chip with AuSn deposition film for flip-chip bonding, it is necessary to manufacture a jig for each electrode shape, which increases the cost and complicates management.

-

After

Can be applied in any design by changing the program of the dispense robot.

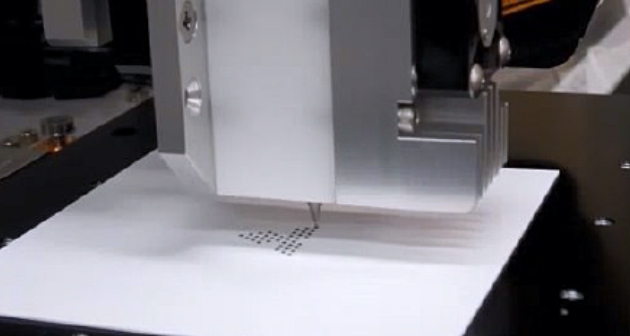

MOVIE

There are three possible construction methods for AuSn paste:

Printing

Dispensing

Pin transfer

ADVANTAGE

-

ADVANTAGE01

The shape can be changed freely just by adjusting the settings of the printing mask or dispenser.

-

ADVANTAGE02

The thickness of the joint material can also be adjusted by changing the settings of the printing mask or dispenser.

OTHER SOLUTIONS

Other solutions for AuSn paste

-

AuSn PASTE

Bond strength is not stable due to substrate roughness

-

AuSn PASTE

The chip is misaligned when bonding

-

AuSn PASTE

Hope to reduce the cost of the cleaning process

-

AuSn PASTE

There are problems when using paste in mass production

Other related solutions

This solution utilizes

Mitsubishi Materials' AuSn paste.