INSULATING SUBSTRATE

Solution

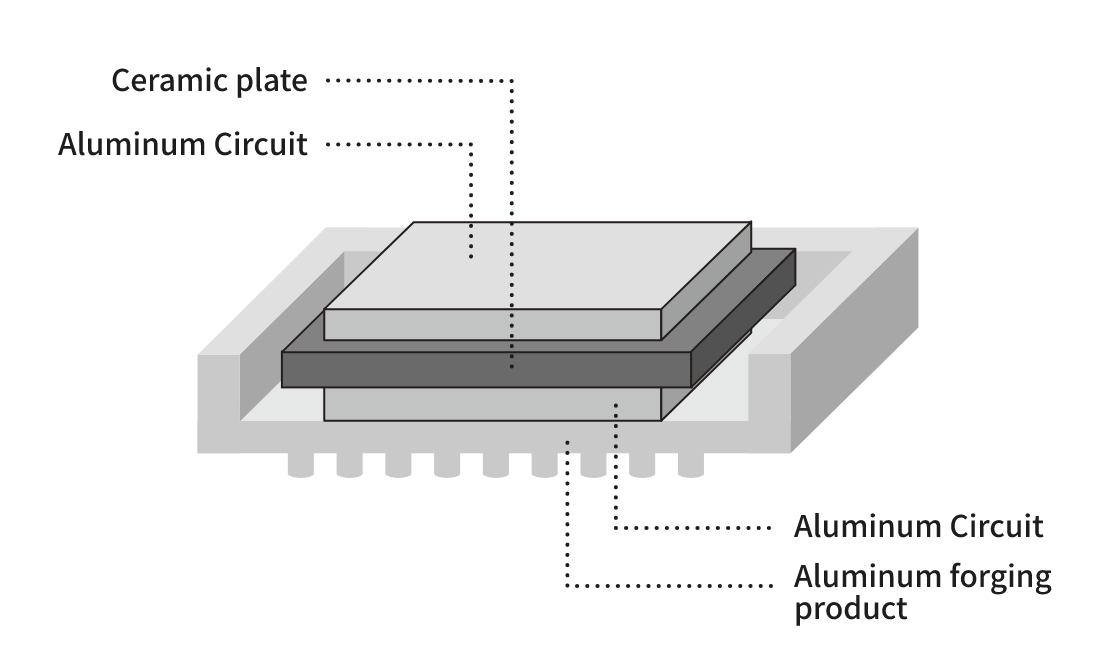

Proposal of heat sink

integrated structure

Challenge

Hope to realize an efficient cooling structure

- Hope to reduce the number of mounting dies and occupation area of insulating substrate.

- Hope to realize high efficiency cooling structure power module.

- Hope to consider development of heat sink integrated insulating substrate, but don’t know whether component and material combination is suitable.

Solution Overview

In order to release generated heat more efficiently from die which is mounted on the circuit layer, commonly heat sink is bonded to the other face side of insulating layer, but we could propose suitable specification for various kind of components and materials combination by use of our know-how of bonding insulating substrate and heat sink.

Effect

-

Before

Need to procure insulating substrate and heat sink individually.

-

After

Realizing man-hours reduction, owing to procurement of heat sink integrated insulating substrate.

-

Before

Hope to reduce pressure loss of water-cooling structure, but there is a limit to satisfying the required heat resistance.

-

After

Owing to development of heat sink structure, achieved to reduce pressure loss.

ADVANTAGE

-

ADVANTAGE01

Owing to heat sink integrated structure, you can simplify manufacturing process.

-

ADVANTAGE02

Utilization of our simulation technology, you can realize optimization of water-cooling structure.

-

ADVANTAGE03

Utilization of our simulation technology, you can realize optimized heat sink shape.

OTHER SOLUTIONS

Other solutions for insulating substrate

-

INSULATING SUBSTRATE

Hope to reduce the thermal resistance of the power module

-

INSULATING SUBSTRATE

Hope to improve reliability of the power module

Other related solutions

-

AuSn PASTE

Hope to flexibly change the thickness and shape of AuSn

-

THERMISTOR SENSOR

Want a heat-resistant product compatible with SiC power semiconductors

-

THERMISTOR SENSOR

Hope to measure sudden temperature changes with good response

-

THERMISTOR SENSOR

Hope to discuss the structure and shape of the sensor

This solution utilizes

Mitsubishi Materials' insulating substrate.

( Responsible Dept.: Monozukuri and R&D Strategy Dept.)