News

April 23, 2025

Mitsubishi Materials Corporation

"Metal Matrix Composite" with

High Thermal Conductivity, Low Thermal Expansion, and Excellent Workability

Mitsubishi Materials Corporation ("MMC") has developed a "metal matrix composite" that achieves high thermal conductivity, low thermal expansion, and excellent workability simultaneously (see Figure 1).

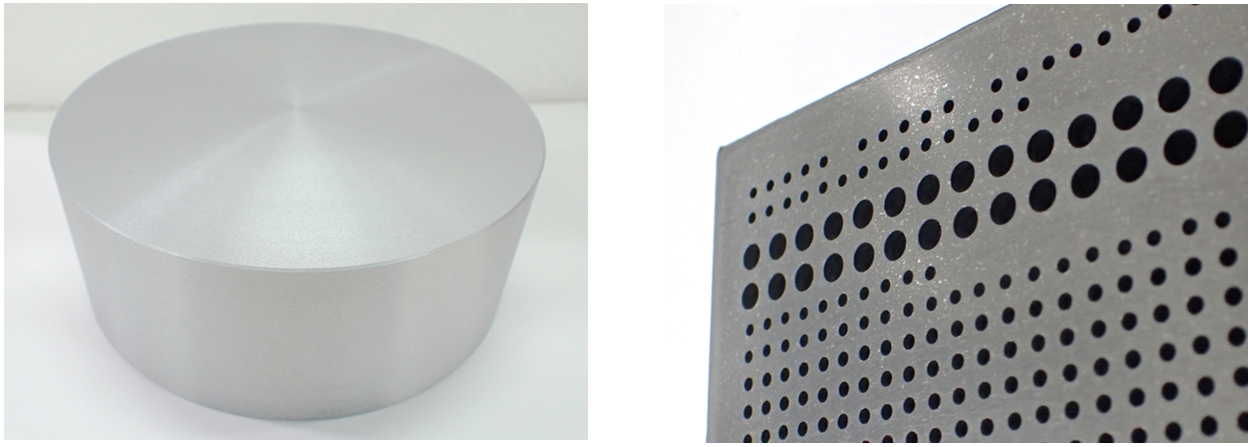

Figure 1: Example of the appearance of the newly developed metal matrix composite

(Left: Turning of cylindrical material / Right: Drilling of plate material)

Recently, the heat generated by semiconductors used in xEVs and other applications has increased due to their higher output. Additionally, semiconductor manufacturing equipment requires more precise temperature control. As a result, there is a growing demand for advanced thermal management in semiconductor assembly components and parts for semiconductor manufacturing equipment compared to the past. To meet these needs, a metal matrix composites that combines the high thermal conductivity (*1) of metals with the excellent mechanical properties of ceramics is required.

Among these, aluminum silicon carbide (Al-SiC), which is composed of aluminum (metal) and silicon carbide (ceramic), is used in components that require high thermal conductivity and low thermal expansion coefficients (*2). However, there have been challenges in achieving a well-balanced performance of certain properties due to manufacturing methods. The manufacturing methods for Al-SiC include infiltration methods (*3) and casting methods. In the infiltration method, aluminum must infiltrate to the center of the silicon carbide skeleton, limiting the shapes that can be produced to thin plates. Additionally, while the thermal expansion coefficient is small because silicon carbide is the main material, there are issues with insufficient thermal conductivity and workability. In the casting method, it is difficult to evenly distribute silicon carbide within the composite material, and to sufficiently reduce the thermal expansion coefficient, a large amount of silicon carbide is needed, which tends to decrease the thermal conductivity.

Therefore, we successfully developed a new metal matrix composite that balances high thermal conductivity and low thermal expansion while also having excellent workability by utilizing the powder metallurgy technology we have cultivated.

This metal matrix composite is designed with a structural organization (a three-dimensional network structure of the metal matrix) that allows the metal matrix in the composite to remain continuous and not be interrupted by ceramic particles. For example, the newly developed Al-SiC achieves a thermal conductivity greater than that of aluminum alloys while realizing an extremely low thermal expansion coefficient (see Figures 2 and 3). Furthermore, due to the low content of silicon carbide (ceramics), it possesses excellent workability like that of aluminum (metal), allowing for the application of general metal processing methods.

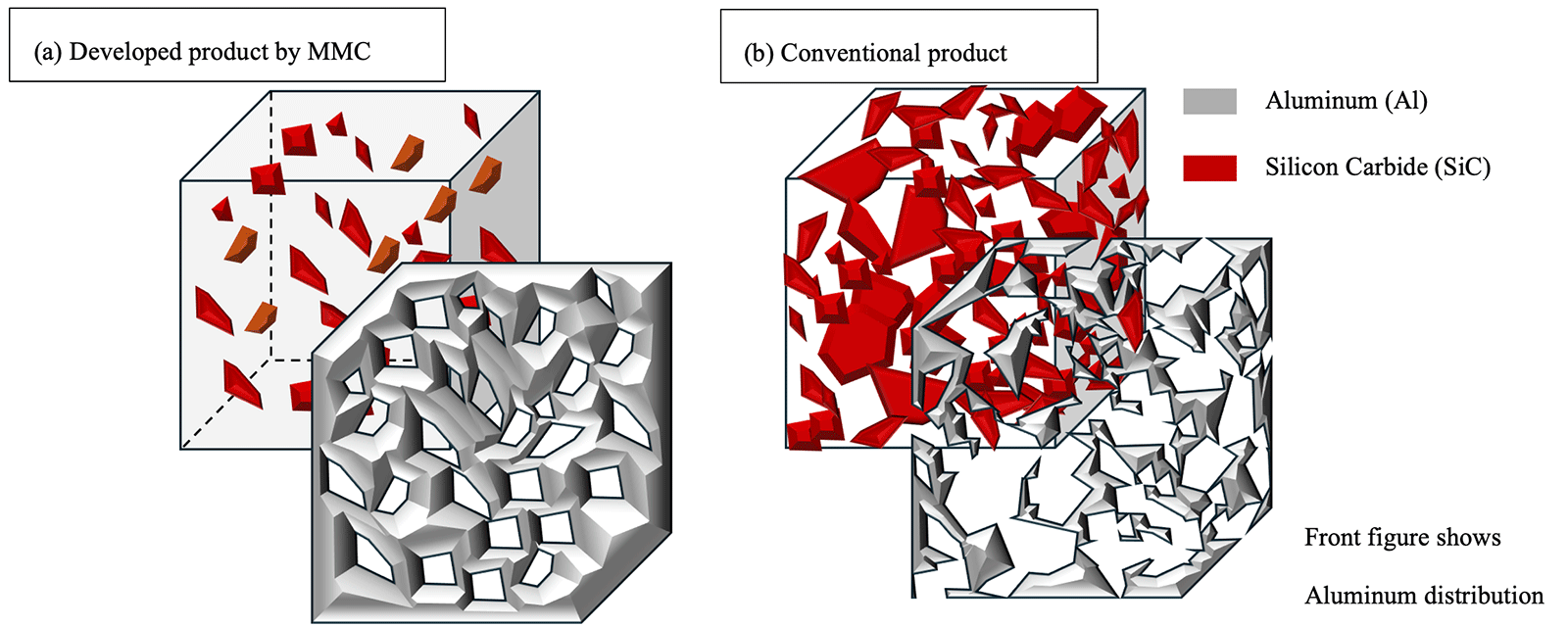

Figure 2: Image of the structural organization of the newly developed Al-SiC (*)

(*) Developed product has a structure where fine particles of silicon carbide are uniformly dispersed, and the aluminum part remains continuous without interruption.

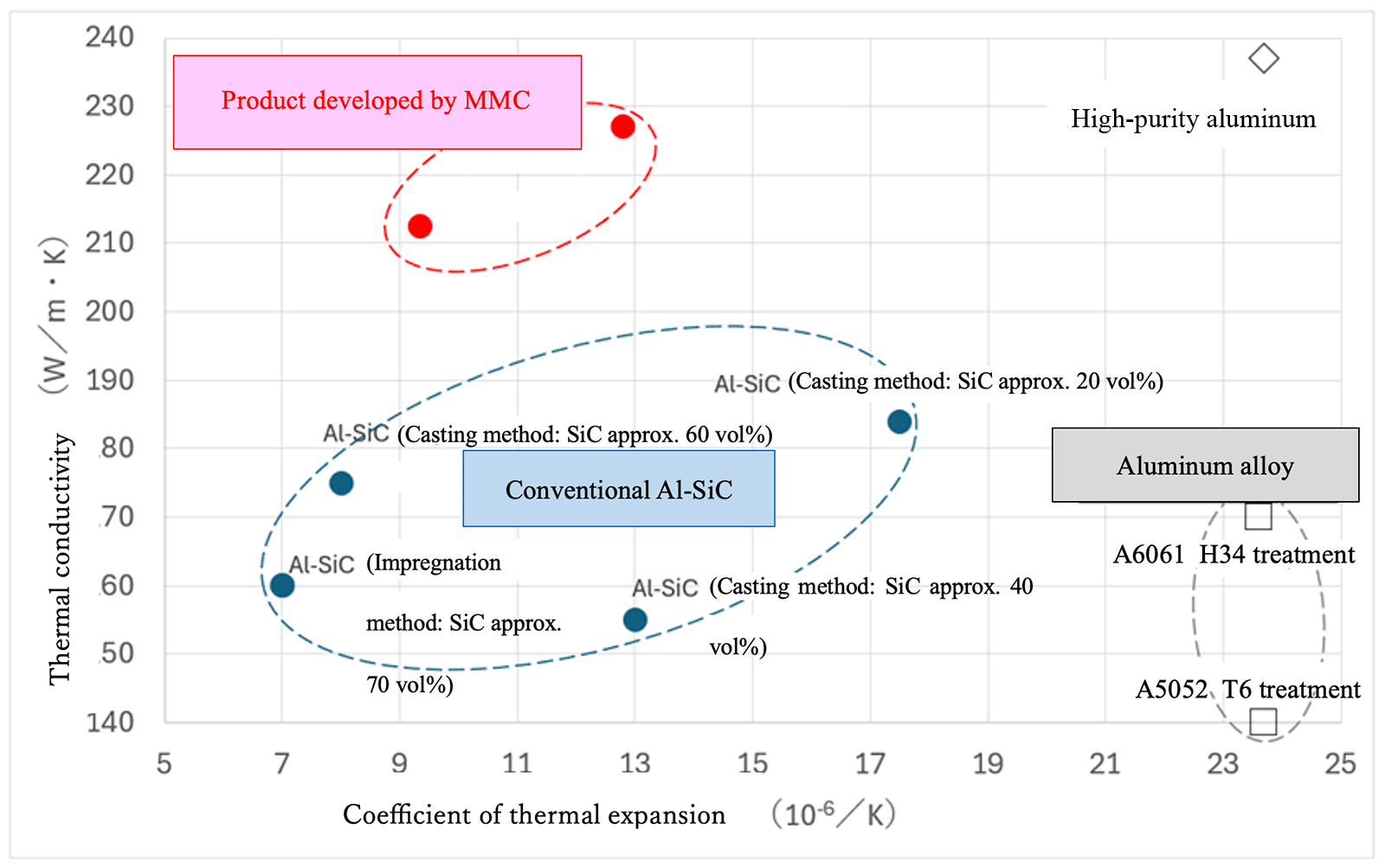

Figure 3: Properties of the metal matrix composite (Al-SiC) developed by us (*)

(*) Developed product exhibits a well-balanced performance of high thermal conductivity and low thermal expansion coefficient compared to conventional Al-SiC.

Moreover, the new metal matrix composite can vary the combinations of different metals and ceramics, as well as their mixing ratios, allowing it to meet diverse material property needs for thermal management components.

Our Group has set "For people, society and the earth, circulating resources for a sustainable future" as "Our Commitment." Moving forward, we will continue to create new materials, supply unique high-performance materials and products, and provide optimal solutions tailored to our customers' needs, working towards the realization of Our Commitment.

- (*1)

- A value that represents the ease of heat transfer of a material. With a temperature difference of 1 K between the two sides of a 1m-thick material assumed, it is represented by the amount of heat that flows through 1 m2 of the material in 1 second [W/(m・K)].

- (*2)

- The coefficient of thermal expansion used for metal materials is generally the coefficient of linear expansion, which indicates the rate at which the length or volume of an object expands per temperature as the temperature rises. The units used are per Kelvin (/K) or per ℃ (/℃).

- (*3)

- A method of impregnating porous silicon carbide with molten aluminum.

<Contact details for inquiries>

Corporate Communications Dept.

+81-3-5252-5206