- Home

- Products & Business

- Metals and Resource Circulation Business

Metals and Resource Circulation Business

METALS COMPANY

Providing Stable Supply of Metal Materials and Recycling of Metal Resources as Our Mission

The roots of our Metals Business trace back to 1873 when the Company acquired the Yoshioka Mine. Metal materials such as copper are essential in many industries. We have supported the development of Japanese industry and society across centuries by providing metal materials. Our supply destinations have now expanded globally.

Furthermore, we have developed a recycling system for recovering metal resources such as gold, silver, tin, lead and bismuth not only from the so-called urban mine of printed circuit board waste and other scrap materials (E-scrap), but also by efficiently disassembling discarded products such as home appliances and automobiles and incorporating them in smelting and other processes.

Business Summary

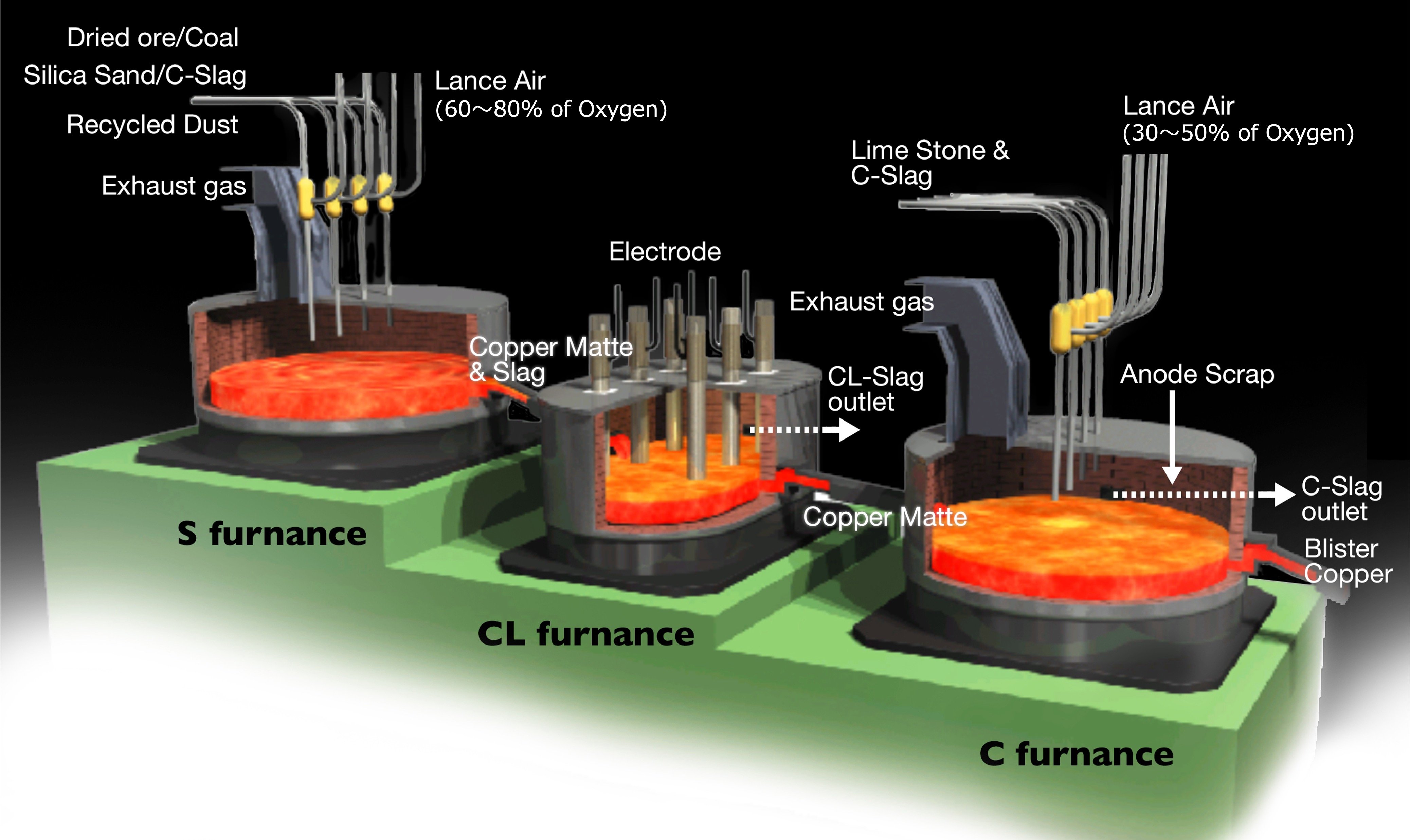

The Mitsubishi Process

The Mitsubishi Process

1kg Gold BarElectrolytic Copper

1kg Gold BarElectrolytic Copper

Resources Business

The mining sector invests in overseas copper mines to ensure the stable procurement of copper ore, the raw material used for smelting, and to meet the growing global demand for copper.

Smelting Business

The smelting and refining sector uses the advanced technological capabilities that enabled the development of the proprietary Mitsubishi Process, a highly efficient and environmentally-clean smelting method, which we use to smelt raw materials such as ore and E-scrap, allowing us to produce high-quality electrolytic copper, gold, silver, PGMs (such as platinum and rhodium), tin, lead, and other metals, as well as by-products such as sulfuric acid.

We offer an accumulation plan called "My Gold Partner" for gold, silver and platinum, providing an alternative for private investors' asset building.

Resource Recycling Business

In FY2024, we integrated our Environmental Recycling Business into the Metals Business and strengthened our system to allow more efficient recycling and utilization of discarded products such as home appliances and automobiles as metal resources.

Targets and Strategy

Mantoverde Mine (Chile)

Mantoverde Mine (Chile)

In the mining sector, we will develop new mines to increase the procurement amount under off-take agreements from invested mines.

In the smelting and refining sector and the resource recycling sector, we aim to become a key player in the resource recycling loop by further expanding the scope and scale of recycled products beyond E-scrap, for which we now have the world's highest processing capacity, as well as by strengthening cooperation in our value chain with a focus on copper.

Topics

World's Top-ranked E-Scrap Intake and Processing Capacity

Examples of Receiving and Processing E-Scrap

Examples of Receiving and Processing E-Scrap

Known as E-scrap, discarded printed circuit boards of various electronic devices such as home appliances, personal computers, mobile phones, smartphones, and network devices have gained attention in recent years as a new source (known as the urban mine) of precious smelting materials because they contain high concentrations of valuable metals such as gold, silver, copper, and palladium.

Furthermore, amid growing environmental concerns, the amount of E-Scrap recovered is expected to increase in line with the higher recycling rates of home appliances and other items.

Taking advantage of the Mitsubishi Process for continuous copper smelting, a unique technology for smelting precious metals with the lowest environmental impact in the industry, our Group has been promoting the expansion of E-Scrap receiving and processing. Through the combined operations with Onahama Smelting and Refining Co., Ltd., our group company, we are working to expand this business further and achieve the leading share of the world market in terms of processing volume.

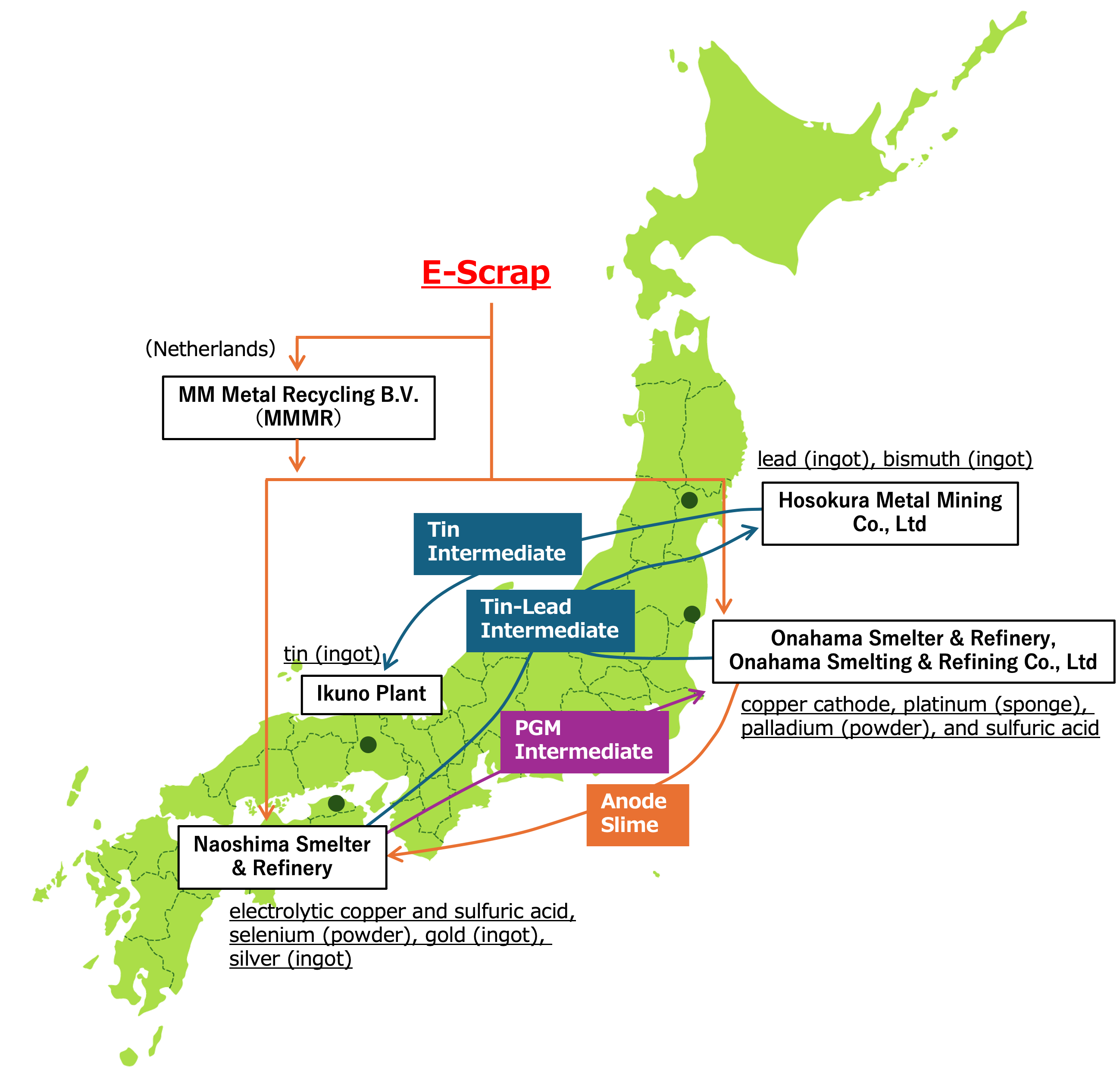

Promotion of material flow optimization

In addition to copper smelting, we also have the advantage of having lead smelting, tin smelting, precious metal smelting, and PGM refining capabilities within the Group, and we are working on measures for recovering various valuable metals even more efficiently by turning the Group into a single smelting system to build process flows across production bases.

For example, by organically linking together the areas in which each production base excels, such as efficiently processing and recovering lead-containing by-products generated by copper smelters at lead smelters, and efficiently processing and recovering tin-containing by-products generated by lead smelters at tin smelters, we aim to establish a robust business that is immune to changes in the external environment.

Material Grid

Material Grid

History

Naoshima Smelter & Refinery (1929)

Naoshima Smelter & Refinery (1929)

Naoshima Smelter & Refinery (2015)

Naoshima Smelter & Refinery (2015)

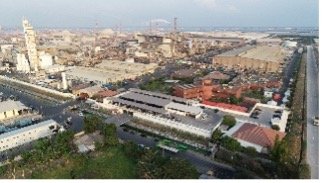

PT. Smelting

PT. Smelting

Gresik Copper Smelter & Refinery

Our Metals Business got its start in 1873, when Mitsubishi founder Yataro Iwasaki acquired and began operations at the Yoshioka Mine in Okayama Prefecture. In 1887, we also acquired a mine in Osarizawa. Full-fledged smelting and refining operations commenced in 1896, when we acquired the Ikuno and Sado mines and a refinery in Osaka from the Japanese government.

In 1917, Naoshima Smelter & Refinery was established as the central smelter of Mitsubishi Goshi Kaisha (Limited Partnership), the predecessor of Mitsubishi Materials Corporation, and, in 1974, commercial use of the Mitsubishi Process began on site.

The resource recycling sector, which was integrated in FY2024, was the first in the world to launch a home appliance recycling business utilizing the technology we have cultivated since our founding and has led the industry through close collaboration with home appliance manufacturers. By strengthening cooperation with the smelting process for non-ferrous metals, we are promoting further resource recycling.

| 1873 | Acquired and began operations at the Yoshioka Mine |

|---|---|

| 1887 | Acquired and began operations at the Osarizawa Mine |

| 1896 | Acquired the Ikuno Mine, the Sado Mine and a refinery in Osaka from the government |

| 1917 | Established the Naoshima Smelter & Refinery |

| 1934 | Acquired the Hosokura Mine (current Hosokura Metal Mining Company) |

| 1958 | Established the Akita Smelter & Refinery |

| 1963 | Established Onahama Smelting and Refining Co., Ltd. |

| 1985 | Participated in Escondida Mine, Chile |

| 1987 | Closed the Hosokura Mine. Closed Akenobe (Ikuno) Mine, Ikuno Plant specialized in tin recycling |

| 1990 | Closed the Osaka Smelter & Refinery, established the Sakai Plant |

| 1994 | Hosokura Smelter & Refinery Company (current Hosokura Metal Mining Company) started recycling lead-acid batteries |

| 1996 | Established PT. Smelting in Indonesia Discontinued zinc smelting at Akita Smelter & Refinery |

| 1997 | Participated in Los Pelambres Mine, Chile |

| 1999 | Established East Japan Recycling Systems Corporation |

| 2004 | Established Chubu Eco Technology Co., Ltd. |

| 2013 | Participated in Zafranal Copper Project, Peru |

| 2021 | Participated in Mantovelde Mine, Chile |

Products

Metals and Resource Circulation Business Related Products

Major Affiliated Companies

- Onahama Smelting & Refining Co., Ltd.Production of copper cathode, platinum sponge, and palladium powder

- Hosokura Metal Mining Co., Ltd.Production of lead ingot and tin ingot

- PT. SmeltingProduction of copper cathode

- MM Metal Recycling B.V.Collection and Sampling of E-scrap

- East Japan Recycling Systems Corp.Recycle of home appliance products

- Chubu Eco Technology Co., Ltd.Recycle of home appliance products

Related Websites

List of Plants

- Naoshima Smelter & Refinery

- Ikuno Plant