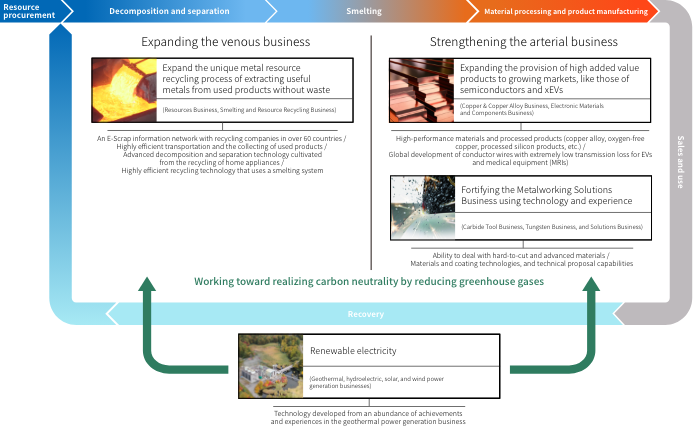

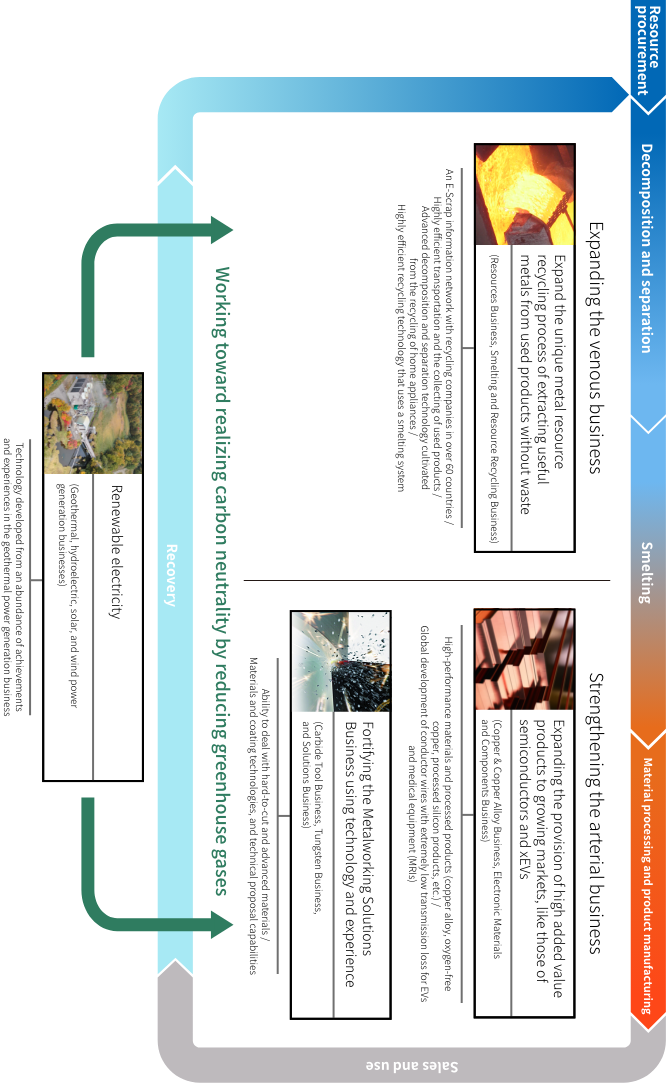

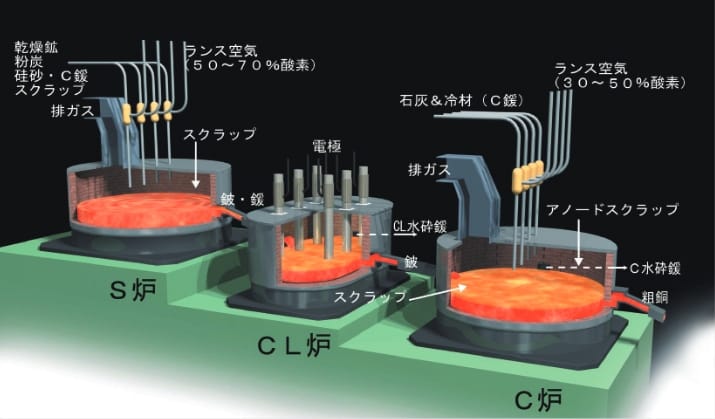

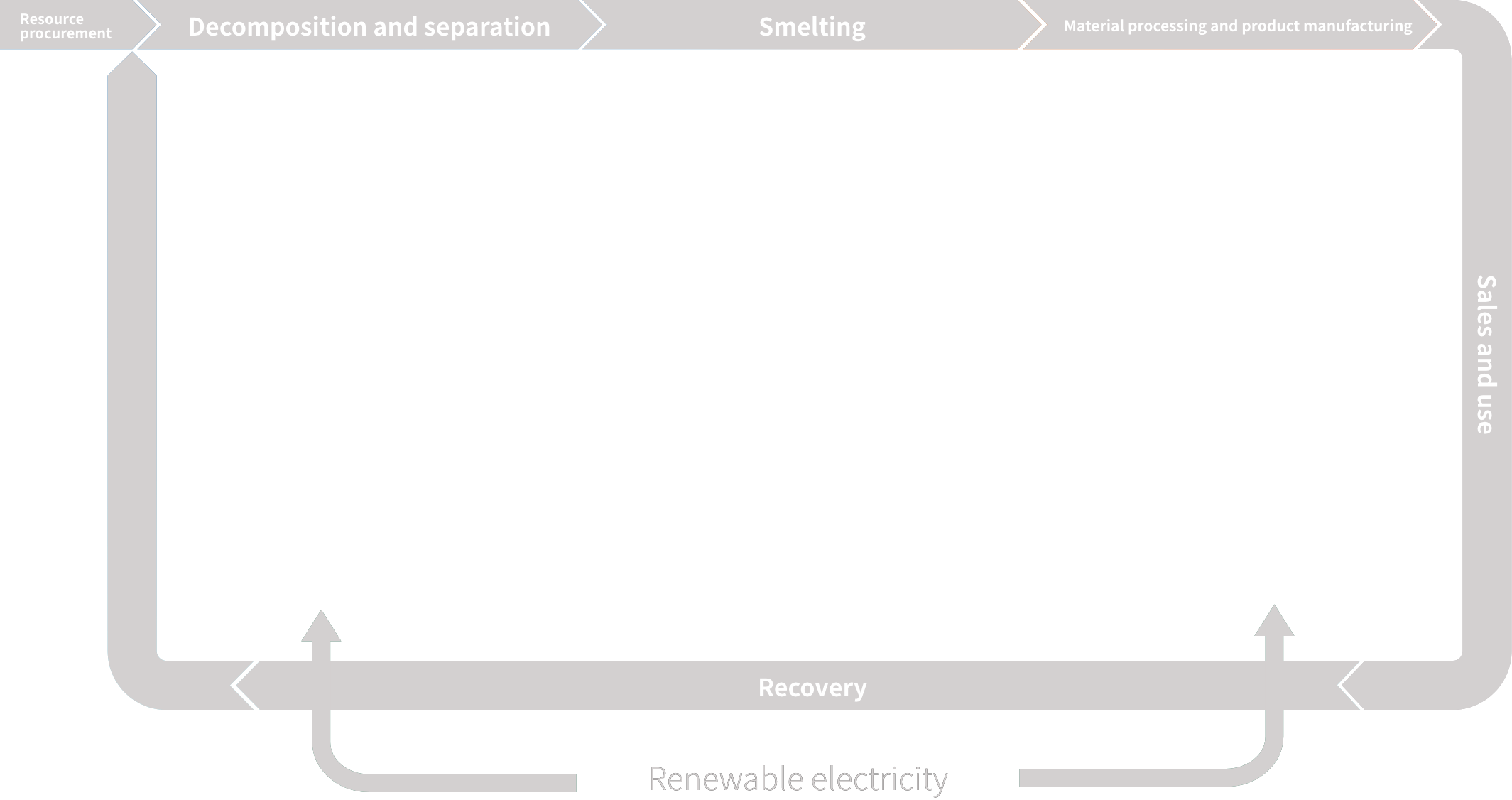

Decomposition and separation

Decomposing complex

metal compounds

metal compounds

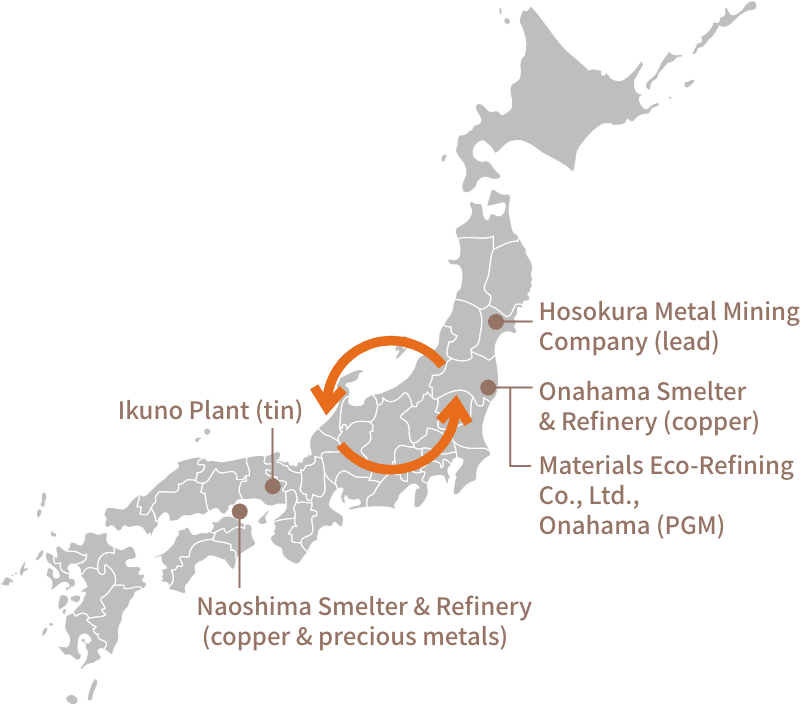

We have developed the home appliance recycling business based on our mine and mineral processing techniques, which have been cultivated over many years. We utilize our advanced skills for decomposing and separating used products.

Decomposition and separation