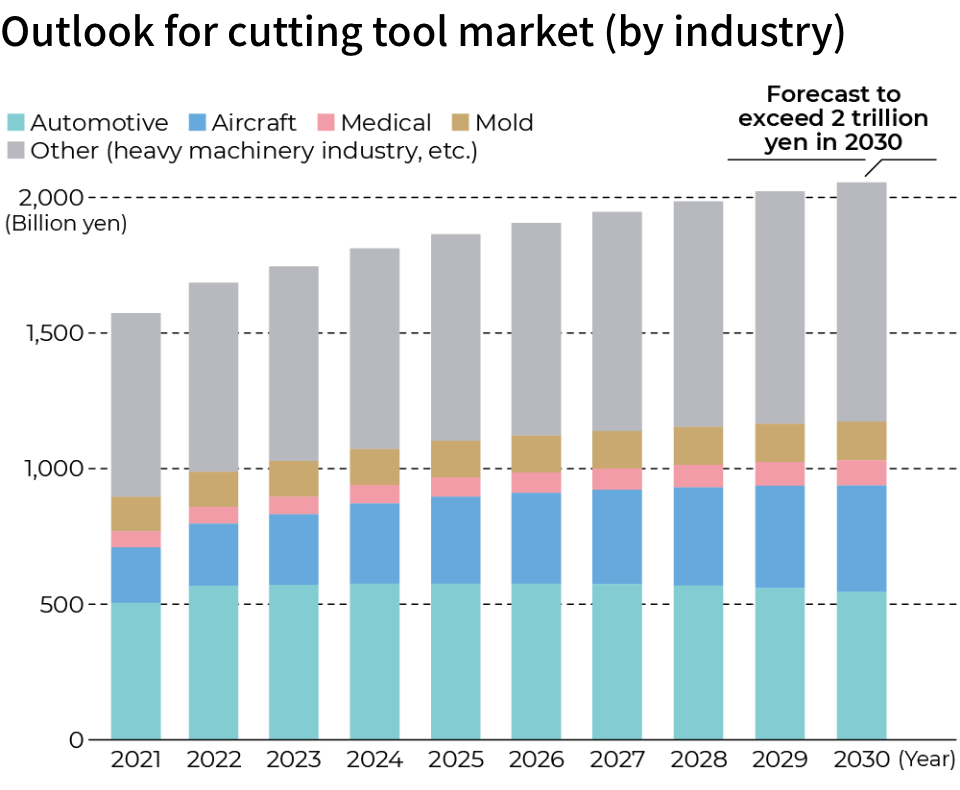

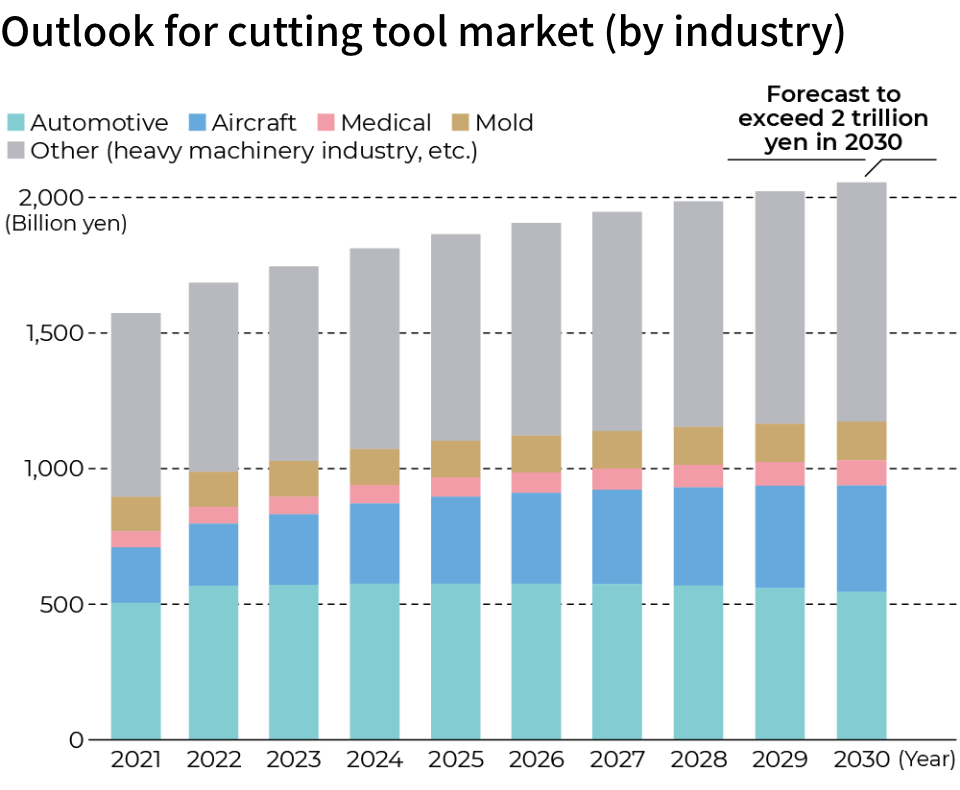

Increase in demand expected

across industries worldwide

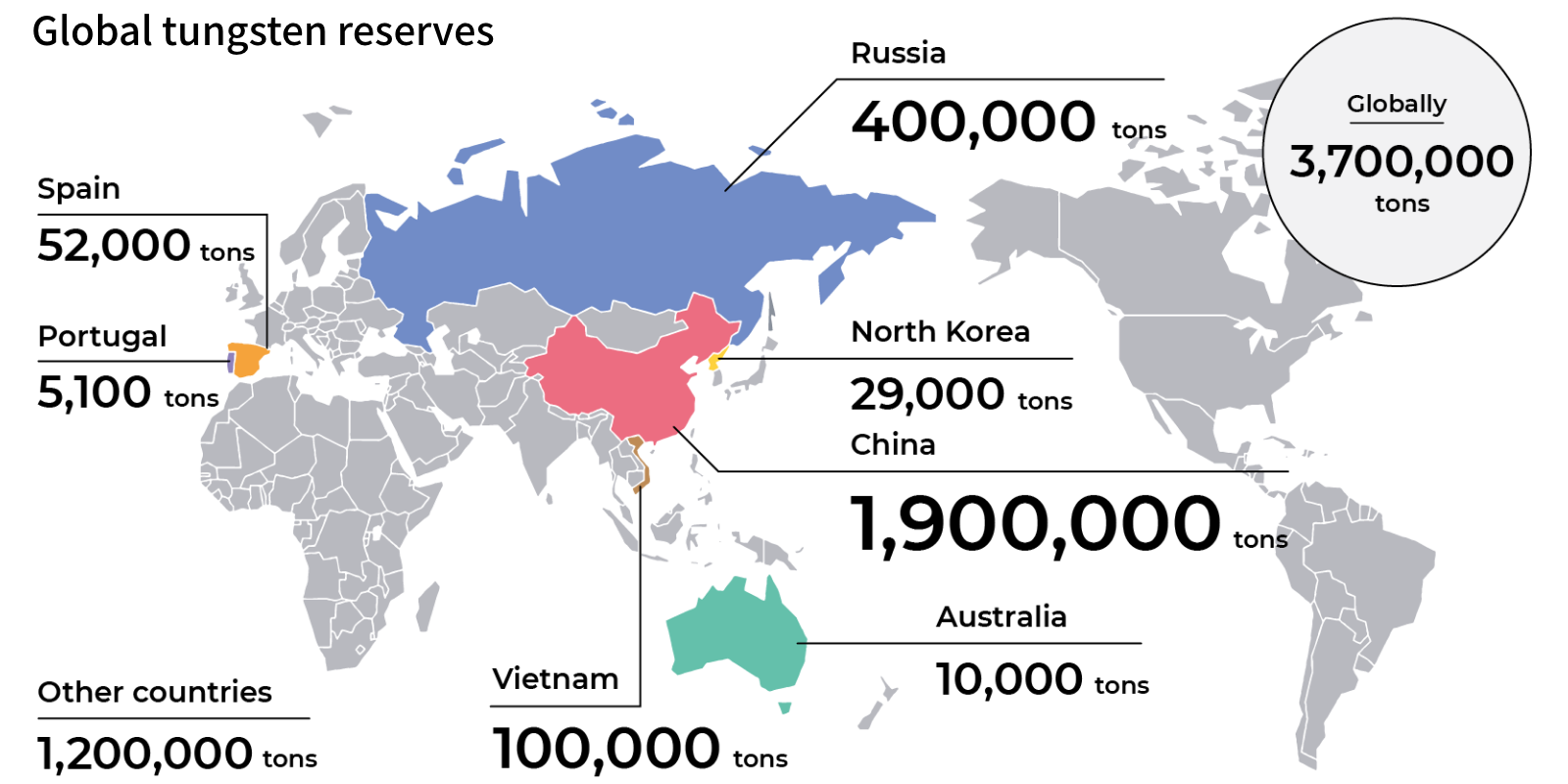

Global Supply

of the Promising Material Tungsten

- Home

- Corporate

- Our Commitment

- Guideline to achieve "Our Commitment"

- Our Current Challenges

- Global Supply of the Promising Material Tungsten

The environment around tungsten

and resource circulation as the key to a stable supply

Tungsten is a promising material that is indispensable for the automobile, airplane, medical, and other industries. The size of the tungsten market is often expressed by weight. In 2022, the estimated scale of the global tungsten powder and tungsten carbide powder market was approximately 100,000 tons, with applications for carbide tools accounting for approximately 60,000 tons of the total. Under these circumstances, Mitsubishi Materials has set a goal of increasing the supply of tungsten for electronic parts by nearly 30% in the Medium-term Management Strategy FY2031.

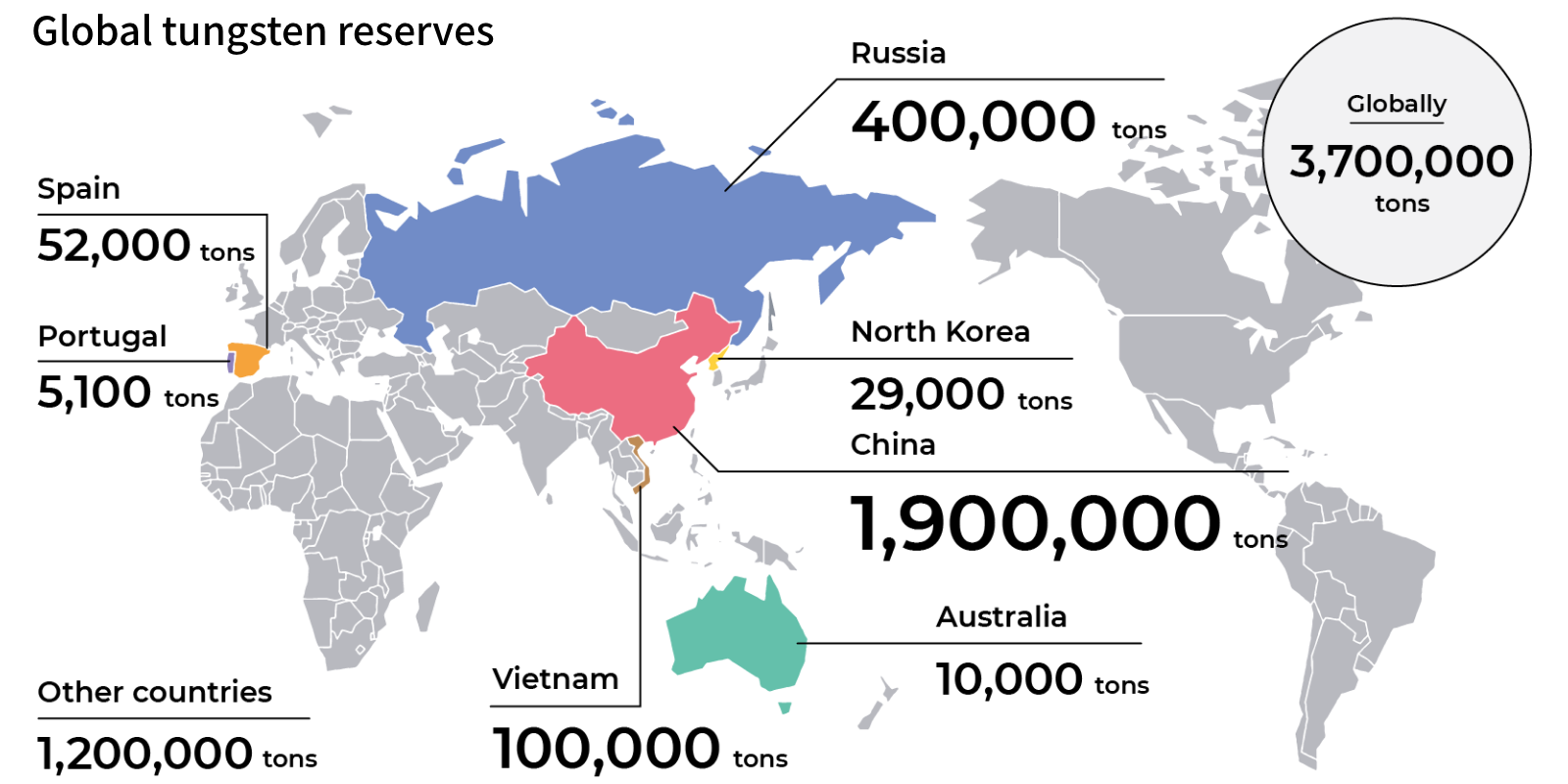

With technological advancements, the demand for tungsten is expected to grow. However, its procurement risk is also increasing. This is because approximately 50% of tungsten is reserved in China, and 85% of the global supply depends on the country. For this reason, it is crucial to mitigate the risk of being unable to procure the material due to future global situations.

To achieve this, the Mitsubishi Materials Group aims to reach a recycled tungsten ratio of over 80% for carbide tools by the fiscal year ending March 2031 as part of the Medium-term Management Strategy FY2031. The key to realizing this goal is expanding the collection of tungsten scraps and improving recycling capabilities--in other words, strengthening resource circulation.

In that regard, JAPAN NEW METALS Co., Ltd. a Group company, is the only company in Japan that possesses tungsten refining technology that enables the integrated manufacturing of tungsten powder and tungsten carbide powder from tungsten-containing scraps. The company's supply capacity has reached 2,500 tons per year.

In addition, the Group acquired all shares of H.C. Starck Holding (Germany) GmbH, a world-leading tungsten product manufacturer with over a century of history, in December 2024. As a result, our Group has established operational bases for the tungsten business in the major markets of Japan, Europe, North America, and China. Furthermore, this acquisition has grown our Group's annual supply capacity to a world-leading level of approximately 15,000 tons, nearly six times our previous supply capacity.

Aiming to become a global-leading company for tungsten products, our company will consolidate our Group's capabilities to establish an integrated system for global tungsten recycling and further strengthen resource circulation.

Using our expertise

and many years

of operational experience

to turn various kinds

of scraps into

tungsten powder

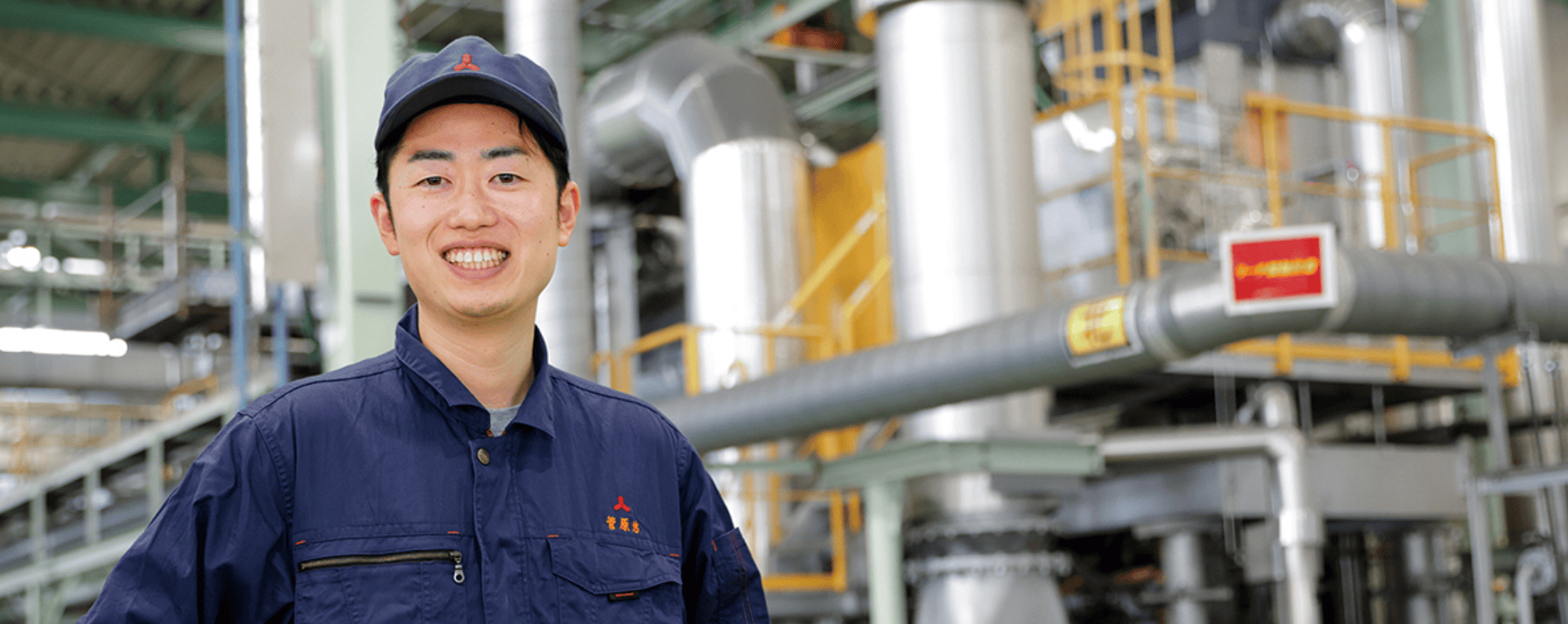

Yuto Sugawara

Production Engineering Group

Akita Plant

JAPAN NEW METALS Co., Ltd.

I am responsible for technical improvement and support for enhancing the productivity of existing recycling processes and the development of new processes. Scraps collected in Japan and overseas are examined for size, quality, and other specifications at our company before being turned into oxide powder through preprocessing and oxidation roasting. Then, impurities are removed from the powder through hydrometallurgy processes. Finally, tungsten powder products (WO3/W/WC) are produced through calcination, hydrogen reduction, and carbonization during the drying process.

The challenge of recycling is that we must standardize the output quality of tungsten powder. In this respect, the Akita Plant's expertise, acquired from many years of operation, enables us to produce high-quality tungsten powder from various kinds of scraps. This achievement is the result of highly-skilled operators and flexible process managers working together.

In addition, I recognize the significance of a future where we will be able to expand our business globally in cooperation with H.C. Starck. This technical partnership may allow us and H.C. Starck to compensate for each other's weaknesses, enhance each other's strengths, and ultimately develop new recycling processes together. I am excited about the potential of this collaboration.

For a stable tungsten supply, stable processing in the recycling processes is of the utmost importance. I believe that diligently working on my current tasks will lead directly to the realization of the previously mentioned goal as part of the Medium-term Management Strategy FY2031. Furthermore, with the increased collection of scraps, there is a demand for the development of recycling processes capable of processing scraps at a low cost. I will proactively take on the challenge of optimizing existing technologies and developing new technology in order to contribute to a stable supply of tungsten.

Expanding the potential

of tungsten according

to social environment

and customers' needs

Yuko Kato

Production Engineering Group

Akita Plant

JAPAN NEW METALS Co., Ltd.

My duty is to produce pure tungsten by removing impurities from scraps while combining technologies, such as ion exchange. The scraps include cobalt and various elements in addition to tungsten. The Akita Plant's ability lies in removing these unnecessary elements through our hydrometallurgy technology, of which we are the only possessors in Japan.

To support a stable tungsten supply and expand its potential, we need to advance technical capabilities that can handle scraps with unexpected impurities and those that are difficult to be processed. The key to achieving this is hydrometallurgy. By identifying the appropriate types and amounts of chemical agents required to remove impurities, I would like to establish a stable recycling method using our accumulated expertise and knowledge.

We are also addressing environmental measures for hydrometallurgy. At our plant, using ammonia results in a high nitrogen content in the wastewater. Excessive nitrogen levels negatively impact water quality. To remain eco-friendly and expand our sustainable business, we aim to collect and recycle ammonia nitrogen.

Moreover, we will improve our operations by establishing recycling technology with low greenhouse gas emissions and conducting other activities, based on social needs. I will also refine our Group's recycling technology in cooperation with other Group members and promote the circulation of tungsten resources in order to expand the Group's recycling business.

Aiming to become a global-leading company of tungsten products, Mitsubishi Materials will continue to take on the challenge of exploring the potential of tungsten by working together as one group and further strengthening resource circulation.