- Home

- Corporate

- Our Commitment

- Guideline to achieve "Our Commitment"

Guideline to achieve

"Our Commitment"

Medium-Term Management Strategy 2031

("FY2031 Strategy")

We have set Our Commitment for the year 2030 to be "For people,

society and the earth, circulating resources for a sustainable future".

The FY2031 Strategy charts the course we must take

to achieve this commitment.

We have set Our Commitment for the year 2030

to be "For people,

society and the earth, circulating resources

for a sustainable future".

The FY2031 Strategy charts the course

we must take

to achieve this commitment.

Growth through Expansion

of Resource Recycling and Enhancing

the Supply of High-performance

Materials

and Products

Since the 20th century, the economic system of mass-production, mass-consumption, and mass-disposal has taken root in society. As a result, various global issues, such as resource depletion and global warming, have been taking place in recent years. It is necessary to address these issues in society, but what should we do to use limited resources without waste for the benefit of people, society, and the earth? As a means to do this, the idea of a circular economy has been attracting attention. In addition to designing products that are easy to recycle and reuse, prolonging their lifespan, and creating a system for sharing goods, we must also view unutilized waste as a resource and recycle it to create a sustainable society. We have decided to incorporate this way of thinking into our newly established vision of "Circulating resources for a sustainable future" for future projects. Our Medium-Term Management Strategy 2031 (FY2031 Strategy) charts the course we must take to achieve this commitment.

The FY2031 Strategy, which will last a period of eight years, encompasses two major phases: Phase 1 (FY2024 - FY2026) and Phase 2 (FY2027 - FY2031). The strategy is designed based on business opportunities and market conditions

surrounding us. The main point of Phase 1 is Strengthening Competitiveness. We will improve profit growth and

profitability while actively investing in medium- to long-term growth areas, such as resource recycling.

The main point of Phase 2 is Business Expansion. We will aim to increase business scale through the expansion of target

areas and further global development.

Business opportunities

for the Company

Expansion

of the resource recycling

Need to increase the rate of recycling metal resources, especially copper, for which demand is increasing, and to respond to recycling in new areas such as used LIBs by accelerating the adoption of xEV

Enhancing the supply

of high-performance

materials and products

Need to respond to the demand for xEV in automobiles, the high-performance materials in aerospace, and the product sophistication in semiconductors

Expansion

of the resource recycling

Need to increase the rate of recycling metal resources, especially copper, for which demand is increasing, and to respond to recycling in new areas such as used LIBs by accelerating the adoption of xEV

Enhancing

the supply of

high-performance

materials

and products

Need to respond to the demand for xEV in automobiles, the high-performance materials in aerospace, and the product sophistication in semiconductors

Phase 1

FY2024 - FY2026

Strengthening

Competitiveness

Improving profit growth and profitability by strengthening cost competitiveness and investing in medium- to long-term growth areas centered on resource recycling

Phase 2

FY2027 - FY2031

Business

Expansion

Expansion of business scale through regional development including overseas, in addition to expansion of target business areas

-

Strengthen metal resource recycling and promote the integration of Metals business and Environmental recycling business

Strengthen metal resource recycling and promote the integration of Metals business and Environmental recycling business

(Strengthening E-Scrap processing, recycling of LIB/xEV materials and tungsten, and strengthening recycling of wrought copper products) -

Supply of products to growing markets such as semiconductors and xEVs, and expansion of carbide tools and tungsten business

Supply of products to growing markets such as semiconductors and xEVs, and expansion of carbide tools and tungsten business -

Promotion of renewable energy projects such as geothermal power generation

Promotion of renewable energy projects such as geothermal power generation

(efforts to achieve 100% self-sufficiency in renewable energy power by FY2051) -

Implementing GHG reduction measures to achieve carbon neutrality by FY2046

Implementing GHG reduction measures to achieve carbon neutrality by FY2046

Metals business

Contributing to the Development

of the Industry through

the Stable Supply

of Metal Resources

Resources business

There is a possibility that supply and demand for copper and other metal resources may become imbalanced in the future.

In particular, copper, whose demand is increasing as an essential material for realizing a decarbonized society, is

expected to see a decrease in its supply volume from mines.

This is why we are actively working on metal resource recycling, a process that involves repeatedly utilizing existing

metal resources, with the aim of securing a stable supply and contributing to Japan's industries and societal

advancement. Additionally, we invest in overseas copper mines, such as Mantoverde Mine in Chile, to procure clean metal

resources.

FY2031 Target

Leader in Resource Recycling of Nonferrous Metals

-

Securing at least 500,000 tons of copper concentrate from mines owned by the Company

Securing at least 500,000 tons of copper concentrate from mines owned by the Company

-

Establishing supply chains for electrolytic copper (SX-EW)

Establishing supply chains for electrolytic copper (SX-EW)

Business

strategy

FY2024 - FY2031

-

Promotion of technological development to recover rare metal resources contained in copper deposits

Promotion of technological development to recover rare metal resources contained in copper deposits

-

Acquisition of copper mining interests and securing copper concentrates through continuous investment in mines

Acquisition of copper mining interests and securing copper concentrates through continuous investment in mines

-

Expansion of electrolytic copper supply through SX-EW operations at copper mines

Expansion of electrolytic copper supply through SX-EW operations at copper mines

Important

measures

FY2024 - FY2031

-

Promotion of the Mantoverde Sulfide Mine Project (including development of new technologies such as cobalt recovery)

Promotion of the Mantoverde Sulfide Mine Project (including development of new technologies such as cobalt recovery)

-

New participation in medium-scale copper mines

New participation in medium-scale copper mines

-

Participation in hydrometallurgy operations at copper mines

Participation in hydrometallurgy operations at copper mines

-

Increasing amount of copper concentrate collected from the current 150,000 tons to 500,000 tons or more in FY2031(Increasing the ratio in the amount of copper concentrate processed in the Naoshima Smelter & Refinery and the Onahama Smelter & Refinery from the current 10% to 30% in FY2031)

Increasing amount of copper concentrate collected from the current 150,000 tons to 500,000 tons or more in FY2031(Increasing the ratio in the amount of copper concentrate processed in the Naoshima Smelter & Refinery and the Onahama Smelter & Refinery from the current 10% to 30% in FY2031)

With the continued growth in copper demand, our goal is to stably secure concentrates. Alongside the objective of securing a three-fold increase in copper concentrate from our mines by FY2031, we also consider the new participation in medium-scale copper mines as an important measure. The Mining & Metallurgy Laboratories will focus on developing new technologies and refining resources-related techniques to ensure the stable collection of rare resources.

Smelting & Resource Recycling business

We are committed to producing high-quality metal materials using the "Mitsubishi Process," a uniquely developed, efficient, pollution-free method for continuous copper smelting. We are also expanding our resource recycling efforts by disassembling used home appliances and automobiles to regenerate metal resources.

FY2031 Target

Leader in Resource Recycling of Nonferrous Metals

-

Major and leading-edge operator in the resource recycling of nonferrous metals

Major and leading-edge operator in the resource recycling of nonferrous metals

-

Expanding processes of nonferrous metal resources not limited to E-Scrap

Expanding processes of nonferrous metal resources not limited to E-Scrap

-

Becoming a core supplier in the resource recycling loop based on the world's top-class electrolytic copper supply capacity

Becoming a core supplier in the resource recycling loop based on the world's top-class electrolytic copper supply capacity

Business

strategy

FY2024 - FY2031

-

Strengthening and expanding the networks to promote resource recycling

Strengthening and expanding the networks to promote resource recycling

-

Expansion of electrolytic copper production capacity

Expansion of electrolytic copper production capacity

-

Increasing the recycling rate by expanding the treatment of recycled products containing metal resources

Increasing the recycling rate by expanding the treatment of recycled products containing metal resources

-

Creation of rare earths and rare metals recycling businesses

Creation of rare earths and rare metals recycling businesses

-

Accelerating business developments in Japan and overseas

Accelerating business developments in Japan and overseas

(E-Scrap, home appliances, automobile recycling)

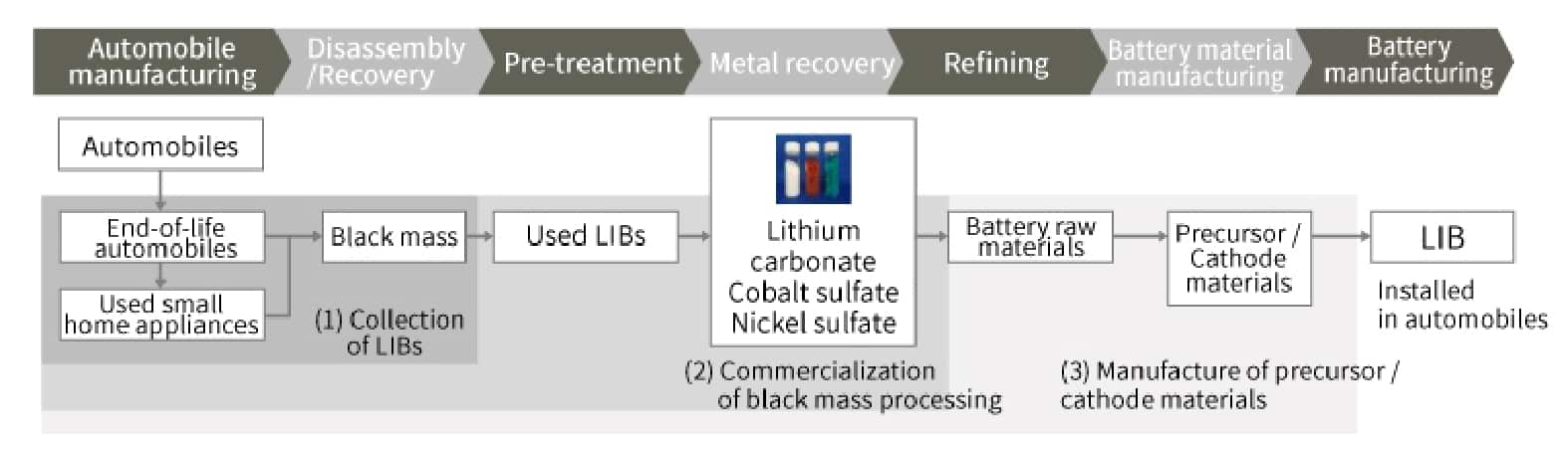

LIB Recycling

-

Ensure global competitiveness through early development of a set of recycling processes from LIBs to battery materials, collection of black mass*, leveraging of the network established in the E-Scrap business, and highly efficient recovery of lithium carbonate, cobalt sulfate, and nickel sulfate from black mass

Ensure global competitiveness through early development of a set of recycling processes from LIBs to battery materials, collection of black mass*, leveraging of the network established in the E-Scrap business, and highly efficient recovery of lithium carbonate, cobalt sulfate, and nickel sulfate from black mass

-

Increase our E-Scrap processing capacities and expand our business areas through three stages: (1) collection of used LIBs from end-of-life automobiles, (2) commercialization of black mass processing in cooperation with business partners, and (3) development of manufacture of precursor/cathode materials

Increase our E-Scrap processing capacities and expand our business areas through three stages: (1) collection of used LIBs from end-of-life automobiles, (2) commercialization of black mass processing in cooperation with business partners, and (3) development of manufacture of precursor/cathode materials

Utilizing our world-class smelting technology and electrolytic copper production capabilities, we strive to expand

nonferrous metal recycling initiatives. Our primary focus is on recycling LIBs, which are expected to be increasingly

discarded with the widespread adoption of xEVs. Concurrently, we are developing technology to collect and refine rare

resources contained in the black mass generated during the LIBs recycling process.

*Black mass: Powders obtained after heat-processing LIBs

Advanced Products

Addressing Demand through the

Power

of High-performance Materials

and Products

Copper & Copper Alloy business

The demand for wrought copper products is growing worldwide due to the expansion of the xEV market, the increasing need for renewable energy, and advancements in healthcare. We utilize electrolytic copper produced through smelting as raw materials to manufacture various wrought copper products, including ingots, strips, plates, and rods, tailoring them for customer needs. We proudly hold the largest market share in Japan. To address the growing demand, we are making investments to enhance our production capacity.

FY2031 Target

Global First Supplier

-

Japan: Establishing a dominant position as Japan's No. 1 manufacturer of wrought copper products as the largest supplier

Japan: Establishing a dominant position as Japan's No. 1 manufacturer of wrought copper products as the largest supplier

-

Overseas: Strengthening key account (KA) strategy based on alloy development capabilities

Overseas: Strengthening key account (KA) strategy based on alloy development capabilities

Business

strategy

FY2024 - FY2031

-

Improve the recycling rate of wrought copper products and establish a scrap platform base

Improve the recycling rate of wrought copper products and establish a scrap platform base

-

Overseas (Luvata): Rapid entry into growing markets (xEV, healthcare, and environment)

Overseas (Luvata): Rapid entry into growing markets (xEV, healthcare, and environment)

-

Expanding sales and strengthening services to overseas customers by looking into new overseas plants to carry out downstream processes, with domestic plants acting as a guiding hand

Expanding sales and strengthening services to overseas customers by looking into new overseas plants to carry out downstream processes, with domestic plants acting as a guiding hand

While enhancing our production capacity for high-performance metal alloys, which are one of our strengths, and supporting the evolution of growth markets, including the xEV market, we will aim to establish an overwhelming position as Japan's largest supplier. Outside Japan, we will aim to further expand business by collaborating with Luvata, our Group company that has a dedicated license for GloBrass®, a next-generation lead-free brass with excellent machinability. Additionally, we will contribute to reducing GHG emissions by increasing the recycling rate for wrought copper products.

Electronic Materials

& Components business

To support the evolution of IT and electronics technology, which encompasses daily necessities such as computers, smartphones, automobiles, and home appliances, we offer unique, high-value-added products that leverage our proprietary materials. Our product lineup is extensive and includes processed silicon products, sealing products, plating chemicals with extremely low alpha-ray emissions for semiconductor electrodes, automotive thermistor sensors, and solar heat-ray shielding paint. Some of our products hold the number one global market share.

FY2031 Target

Global First Supplier

-

Providing products and solutions with added value through concept-in (promoting the adoption of our products at the initial concept-setting stage of product development), focusing on the semiconductor and xEV markets

Providing products and solutions with added value through concept-in (promoting the adoption of our products at the initial concept-setting stage of product development), focusing on the semiconductor and xEV markets

-

Highly profitable business entity and sustainably growing entity that is recognized as an indispensable partner in the market

Highly profitable business entity and sustainably growing entity that is recognized as an indispensable partner in the market

Business

strategy

FY2024 - FY2031

-

Highly capital-efficient management through continual restructuring of the business portfolio

Highly capital-efficient management through continual restructuring of the business portfolio

-

Strategic investment in focal products in growth areas

Strategic investment in focal products in growth areas

-

Developing and securing human resources for the creation of new businesses and the promotion of business alliances

Developing and securing human resources for the creation of new businesses and the promotion of business alliances

-

Improvement of manufacturing capabilities and DX to enhance production sophistication and profitability

Improvement of manufacturing capabilities and DX to enhance production sophistication and profitability

-

Providing business and social value (SDGs) for carbon neutrality

Providing business and social value (SDGs) for carbon neutrality

In April 2023, we established the Semiconductor New Technology & Materials Business R&D Center to create a consistent R&D system across the business unit and drive new business creation. Specifically, we are accelerating exploration of new business opportunities and products related to semiconductor materials and components.

Metalworking Solutions business

Becoming the Strength

of the World's Manufacturing

Metalworking Solutions business

We provide carbide tools used at manufacturing sites of a wide range of industries, including automotive, aerospace,

medical, die and mold, and hygiene.

Additionally, we collect used carbide tools and recycle them as raw materials for tungsten, a rare metal, contributing to the establishment of a recycling-oriented society.

FY2031 Target

A Leading Company in Tungsten Products Recognized by Customers Globally

-

Providing tungsten products and solutions with outstanding technology to manufacturing sites around the world

Providing tungsten products and solutions with outstanding technology to manufacturing sites around the world

-

In addition to the core business of carbide tools, the tungsten business and the solutions business will be the mainstay of earnings

In addition to the core business of carbide tools, the tungsten business and the solutions business will be the mainstay of earnings

Business

strategy

FY2024 - FY2031

Transforming into a truly global company with the aim of

autonomous business development in strategic markets

-

Stable supply of the world's top quality, high-efficiency products utilizing the strength of materials and coating technology (Carbide tools business)

Stable supply of the world's top quality, high-efficiency products utilizing the strength of materials and coating technology (Carbide tools business)

-

Expansion of business scale for rechargeable batteries in addition to carbide tools, etc. (Tungsten business)

Expansion of business scale for rechargeable batteries in addition to carbide tools, etc. (Tungsten business)

-

Strengthen environmental responsiveness (Tungsten business)

Strengthen environmental responsiveness (Tungsten business)

-

Commercialization of solution sales to manufacturing sites (Solution business)

Commercialization of solution sales to manufacturing sites (Solution business)

Utilizing our strengths in proprietary materials and coating technology, we enhance our initiatives in machining difficult-to-cut and new materials. We reinforce a system for collecting used carbide tools and recycling them into tungsten raw materials, thereby contributing to a recycling-oriented society.

Additionally, we ensure a stable supply of raw materials by strengthening the recycling capacities of Japan New Metals Co., Ltd., our Group company. Leveraging globally developed technical centers and digital technology, we offer various metalworking solution services to our customers.

Renewable Energy business

Offering Expertise Cultivated

through

Geothermal and Hydroelectric Power

Generation to Society

Renewable Energy business

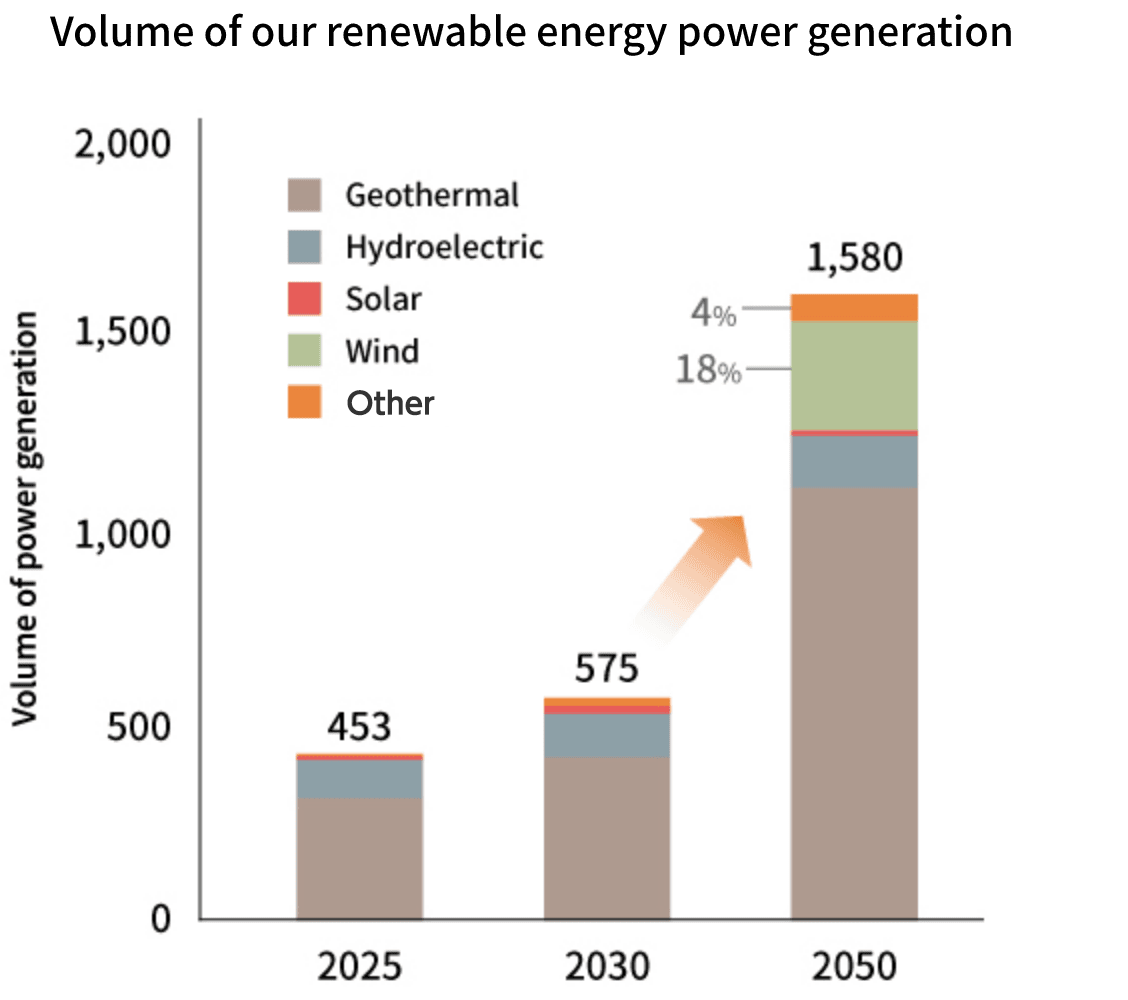

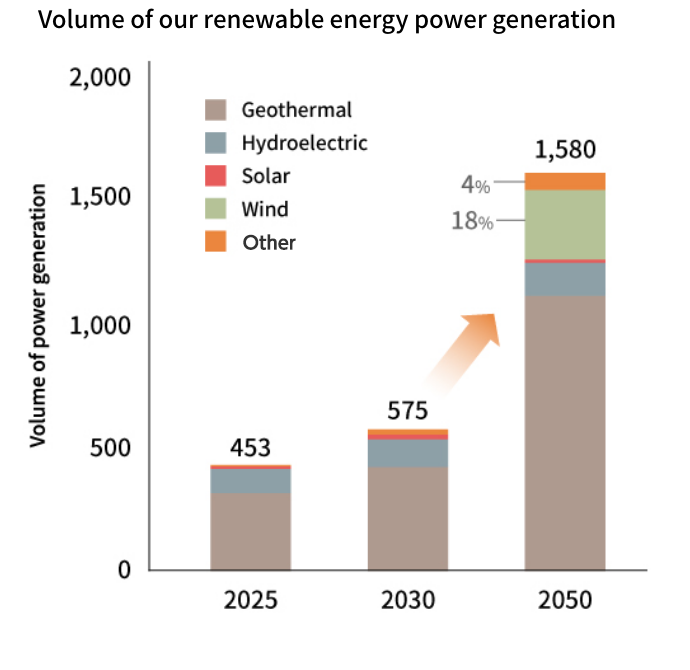

Utilizing this planet's limited resources without waste and creating a sustainable society with cleaner energy are humankind's major issues. Our company has employed renewable energy sources, such as geothermal, solar, and hydroelectric power, to contribute to the realization of a sustainable society. We aim to generate more than three times the current volume of electricity to offset our electricity consumption by FY2051.

FY2031 Target

Expansion of Renewable Power Generation to Achieve 100% Self-sufficiency in Renewable Power Electricity

-

Further expansion of geothermal power generation business

Further expansion of geothermal power generation business

-

Expansion of business areas (wind power generation and power generation-related businesses)

Expansion of business areas (wind power generation and power generation-related businesses)

Business

strategy

FY2024 - FY2031

Consolidate the renewable energy business in the Strategic Headquarters as a company-wide effort to expand the business from a long-term perspective

-

New development at one location every three years to expand business (Geothermal)

New development at one location every three years to expand business (Geothermal)

-

New entrants into wind power generation where power generation costs are expected to decline in the future (Wind)

New entrants into wind power generation where power generation costs are expected to decline in the future (Wind)

Expansion of renewable

energy power generation

-

To generate the volume of electricity that will offset our electricity consumption by FY2051, we are accelerating the establishment of geothermal power generation development systems and expansion of business. We are developing new renewable energy power generation projects, with a primary focus on wind power.

To generate the volume of electricity that will offset our electricity consumption by FY2051, we are accelerating the establishment of geothermal power generation development systems and expansion of business. We are developing new renewable energy power generation projects, with a primary focus on wind power.