News

September 25, 2025

Mitsubishi Materials Corporation

New High-Strength Copper Alloy MSP™5-ESH Developed

- World-class Cu-Mg alloy to replace beryllium copper and titanium copper -

Mitsubishi Materials Corporation (MMC) has developed MSP™5-ESH (Extra Spring Hard), a new high-strength copper alloy, designed for use in automotive electrical components and similar applications. MSP™5-ESH is a solid solution strengthened (*1) copper alloy containing magnesium as the primary alloying element. MSP™5-ESH delivers an excellent balance of manufacturability, performance, and environmental impact compared to conventional high-strength copper alloys.

■Background and Purpose of Development

MSP™5, which MMC began mass production of in 2021, is a copper alloy that features a high level of strength, conductivity, and formability by incorporating a high concentration of magnesium. Without using rare elements such as beryllium, it also offers a cost advantage and has earned high recognition as a material for miniaturized automotive terminals.

The newly developed MSP™5-ESH is a high-strength type in the same series and offers performance characteristics that make it possible to replace beryllium copper and titanium copper in areas where they were previously used. Because these conventional materials are precipitation-strengthened (*2), they require a complex heat treatment process, resulting in higher production costs, reduced quality stability, and greater environmental impact. MSP™5-ESH solves these problems by taking advantage of its solid solution strengthened characteristics.

- (*1)

- A method of strengthening a material by dissolving other atoms (solute atoms) into the matrix of parent atoms (solvent atoms).

- (*2)

- A method of strengthening a material by precipitating other atoms (solute atoms) in the matrix of parent atoms (solvent atoms).

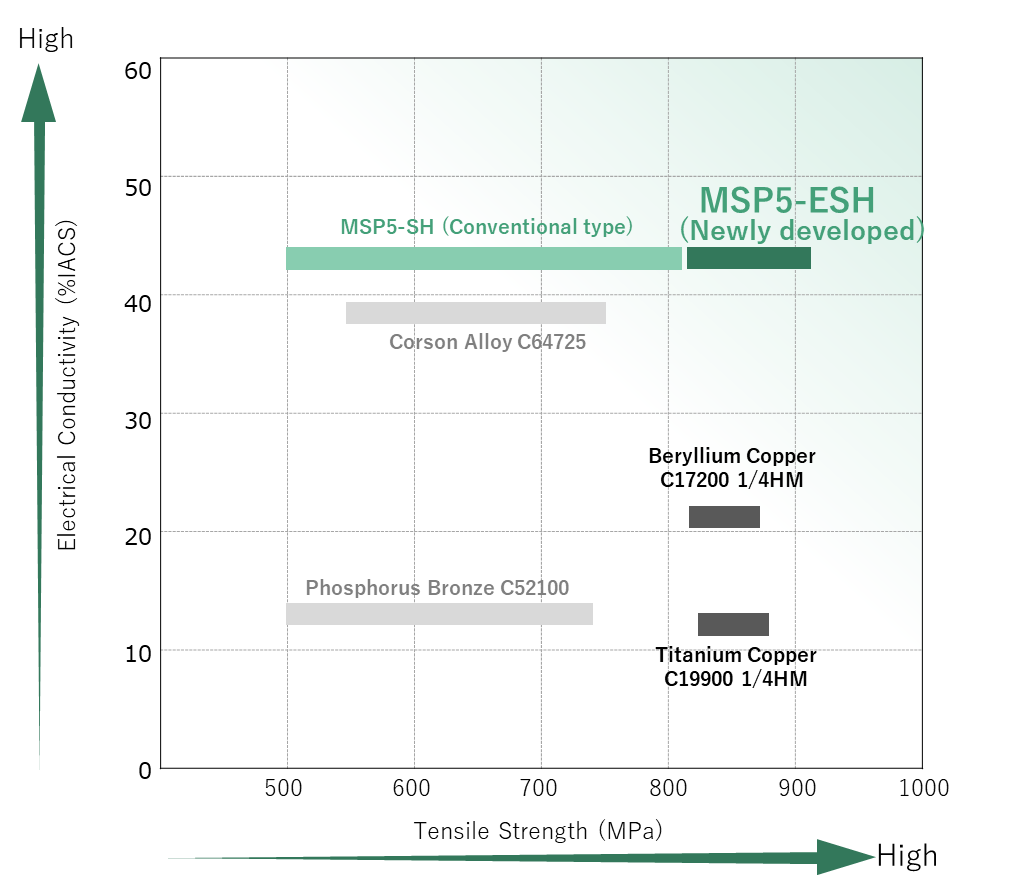

Figure: Comparison of characteristics of MSP™5

Figure: Comparison of characteristics of MSP™5and other alloys (Click the picture to see the enlarged image)

■Technical Features

- Balancing high strength and high conductivity

MSP™5-ESH has the world's highest level of performance among copper alloys, with a tensile strength of approximately 900MPa and a conductivity of 43%IACS. While maintaining the same strength as beryllium copper (C1720 - 1/4HM) and titanium copper (C1990 - 1/4HM), its conductivity is approximately two and four times higher, respectively. The compatibility of electrical and mechanical characteristics not only improves the reliability of automotive components but also contributes to the miniaturization of components and reduction of copper material usage. - Excellent formability

While cracks in high-strength materials are generally a concern during processing, MSP™5-ESH has excellent box bendability and can be processed with a minimum bending radius of R = 0. It also has excellent blanking workability , high dimensional accuracy, and low burr generation, making it highly mass-producible. - Reducing environmental impact

Compared with precipitation-strengthened alloy, the solid solution strengthened MSP™5-ESH has a simpler manufacturing process and does not require complicated heat treatment. This reduces CO2 emissions during manufacturing and contributes to reducing environmental impact.

Mitsubishi Materials Group established Our Commitment as "For people, society and the earth, circulating resources for a sustainable future." Going forward, we will continue to create new materials and supply one-of-a-kind high-performance materials and products to realize Our Commitment.

[Related information]

Press release on April 18, 2024

Received the Science and Technology Award (Development Category) for the First Time in 2024 Commendation for Science and Technology by the Minister of Education, Culture, Sports, Science and Technology

URL: https://www.mmc.co.jp/corporate/en/news/2024/news20240418.html

Press release on May 20, 2021

Start of Full-Scale Production of Copper Alloy "MSP5" for Automotive Small Terminals

URL: https://www.mmc.co.jp/corporate/en/news/2021/news20210520.html

"MSP" series introduction page on the Copper & Copper Alloy business's website

URL: https://www.mitsubishi-copper.com/en/products/materials/msp/

<Contact details for inquiries>

Corporate Communications Dept.

+81-3-5252-5206