News

June 18, 2024

Mitsubishi Materials Corporation

Carbon Footprint Calculation for Electrolytic Copper Awarded Third-Party Verification

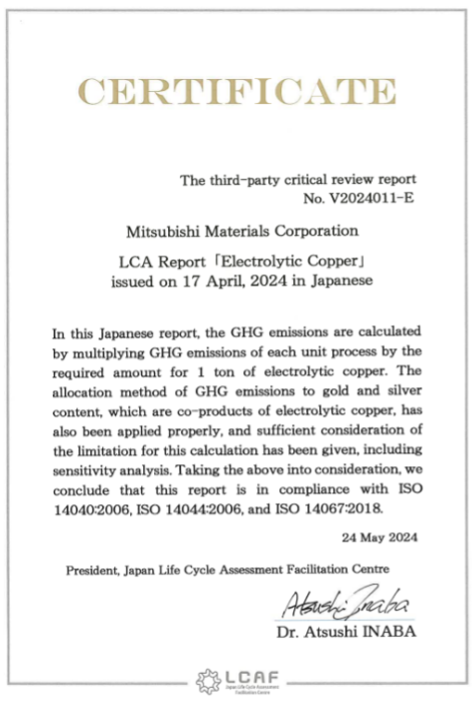

Mitsubishi Materials Corporation ("MMC") calculated the Carbon Footprint of Products ("CFP (*1)") for electrolytic copper produced at MMC Group's copper smelters in Japan and received third-party verification for the results, and obtained a certification that demonstrates the calculation complies with international standards.

The calculation of CFP this time is targeted at our main product, "electrolytic copper," which was produced at Naoshima Smelter & Refinery and Onahama Smelting and Refining Co., Ltd.'s Onahama Smelter & Refinery in the fiscal year ended March 2023.

We calculated the greenhouse gas (GHG) emissions per ton of electrolytic copper production "from Cradle to Gate" (from raw material procurement to product manufacturing and shipment) in accordance with Life Cycle Assessment ("LCA (*2)") and international CFP standards (*3). In addition, our calculation process was subject to a critical review (*4) by "Japan Life Cycle Assessment Facilitation Centre" (President: Dr. Atsushi Inaba), and was determined to comply with the above standards, thereby verifying the objectivity and reliability of our electrolytic copper's CFP by a third-party.

CFP calculations are attracting increasing interest from various sectors, such as governments and industry associations in Japan and abroad, exploring calculation and utilization methods. We will continue to conduct CFP calculations for our other major products to advance our initiatives on climate change.

MMC Group established Our Commitment of "For people, society and the earth, circulating resources for a sustainable future." We aim to realize Our Commitment through the expansion of resource recycling and enhancing the supply of high-performance materials and products.

- (*1)

- Since CFP requires calculation and analysis of GHG emissions at each stage of the life cycle of individual products, this indicator enables the identification of GHG emission reduction measures that should be prioritized or focused not only on the company's business activities but also on the supply chain as a whole from a comprehensive perspective.

- (*2)

- A method for quantitatively evaluating resource inputs, environmental burdens, and environmental impacts over a product's life cycle.

- (*3)

- ISO 14040-2006 Environmental management - Life cycle assessment - Principles and framework

ISO 14044-2006 Environmental management - Life cycle assessment - Requirements and guidelines

ISO 14067-2018 Greenhouse gases - Carbon footprint of products - Requirements and guidelines for quantification - (*4)

- A process in which an LCA expert checks whether the implemented LCA meets the requirements of (*3).

[Related Releases]

January 19, 2024

Significantly Accelerating the Switch to Electricity Derived from Renewable Sources at Sites in the Metals Business

URL: https://www.mmc.co.jp/corporate/en/news/2024/news20240119.html

<Contact details for inquiries>

Corporate Communications Dept.

+81-3-5252-5206