News

November 18, 2025

Mitsubishi Materials Corporation

New High Strength and High Heat Resistance Oxygen-Free Copper MOFC™-HR Multi-Gauge Strip Developed

- Multi-gauge strips enable production of heat dissipation and contact areas using the same material -

Mitsubishi Materials Corporation ("MMC") has developed a new multi-gauge strip (*1) as part of the expansion of the MOFC™-HR (Heat Resistance) lineup, one of the high-performance oxygen-free copper (*2) MOFC™ (Mitsubishi Oxygen Free Copper) series.

■Background and Purpose of Development

With the electrification of automobiles and the spread of renewable energy, materials and components for electrical devices are required to have high electrical conductivity and high heat dissipation performance to handle high currents. Uses for oxygen-free copper, which has excellent electrical and thermal conductivity, are increasing, however it had the problem of insufficient strength and heat resistance in cases where the use of high currents involves rises in material temperature or where production requires heat treatment.

MOFC™-HR is an oxygen-free copper with drastically increased strength and heat resistance while maintaining high electrical and thermal conductivity through MMC's core technologies--high quality oxygen-free copper production technology and material design technology. MOFC™-HR is certified by the Copper Development Association Inc. (CDA) in the United States as oxygen-free copper with an electrical conductivity of 100% IACS or higher (registration number: C10850) and has been valued highly in lead frames for automotive power modules (*3), EV relay components, automotive terminals, etc.

The newly developed MOFC™-HR Multi-Gauge Strip enables the heat dissipation and contact areas of lead frames, terminals, or connectors to be produced using the same material and simultaneously molded.

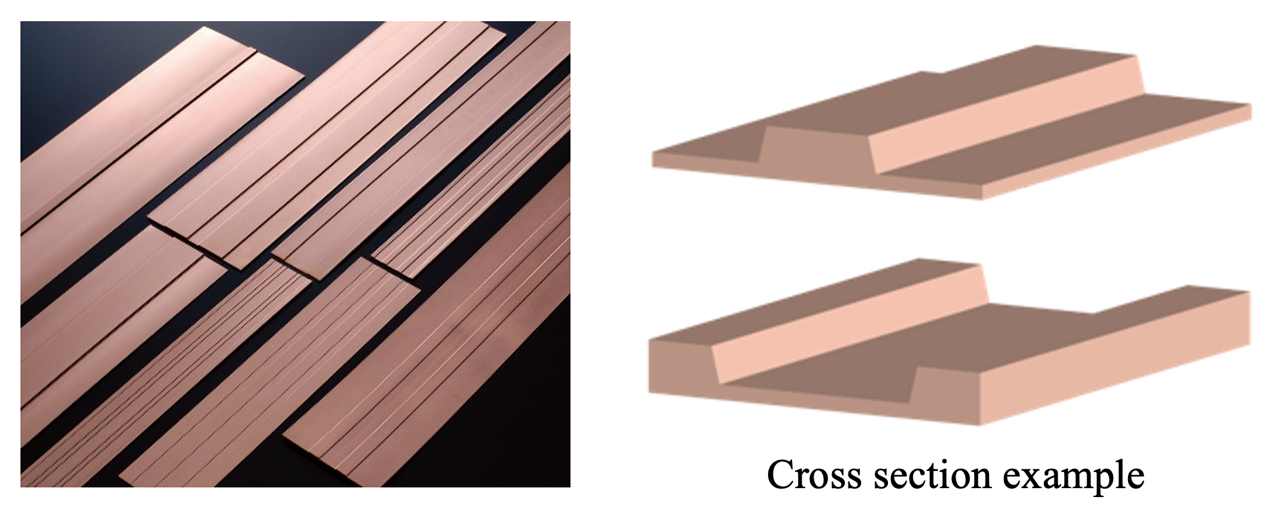

- (*1)

- Stepped strips with two or more different thicknesses to form thick and thin portions across their width (see Figure 1).

- (*2)

- Copper with a purity of 99.95% or more with an extremely low oxygen (oxide, etc.) content.

- (*3)

- A power module is a module used for power control and conversion in xEVs, etc., that combines multiple power semiconductors (including IGBTs and MOSFETs), drive circuits, protection circuits, etc., in a single package.

Figure 1:

Figure 1: Image of multi-gauge strip shapes

■Features

- Production of single-piece components using multi-gauge strips

Each multi-gauge strip has thick and thin sections, which serve as a heat dissipation section (thick) and lead section (thin) in lead frame uses, and a heat dissipation section (thick) and contact section (thin) in terminal/connector uses; this structure allows all these different components to be produced as a single piece using the same material and simultaneously molded. This contributes to the reduction of person-hours in manufacturing control and assembly.

MMC has a proven track record of producing strips in various thicknesses and widths to meet customer requirements. - Achieving high strength and high conductivity simultaneously

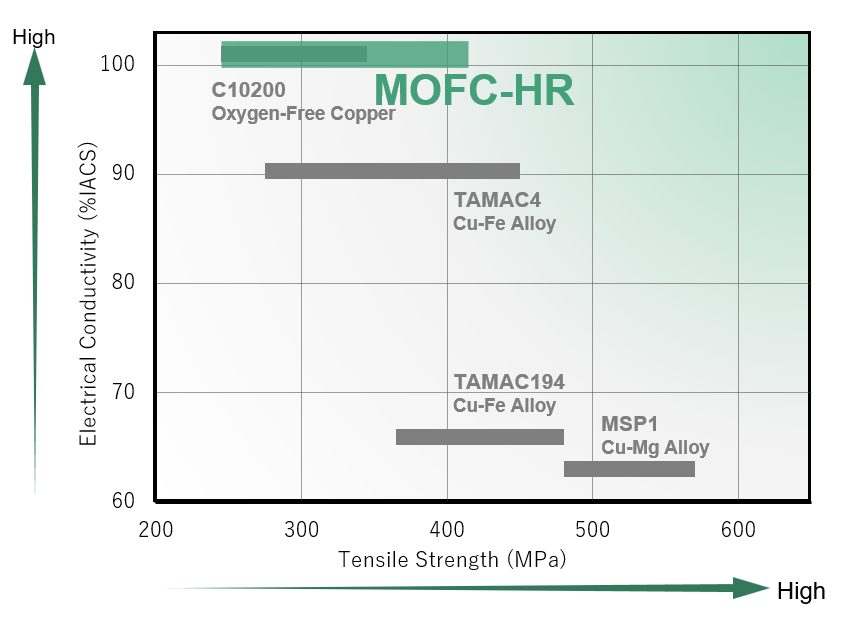

MOFC™-HR maintains equivalently high electrical conductivity (100% IACS) and thermal conductivity (391 W/mK) as oxygen-free copper (OFC), and at the same time, is significantly superior to oxygen-free copper in terms of strength (400 MPa, approximately 25% higher) and heat resistance (half-softening temperature (*4) of 350°C or more, approximately 150°C higher) (see Figure 2).

Imparted with both electrical and mechanical properties, MOFC™-HR is able to enhance the performance of oxygen-free copper and highly conductive copper alloys. Moreover, the excellent properties, which reduce the use of copper materials, contribute to cost reduction and the miniaturization and weight reduction of components.

(Note) "MOFC" trademark registration countries are as follows:

Japan, China, Germany, Finland, the U.K., Hungary, Indonesia, India, South Korea, Mexico, Malaysia, the Philippines, Portugal, Singapore, the U.S.A., Vietnam, Taiwan (Thailand is pending).- (*4)

- An indicator of heat resistance that indicates the heat treatment temperature at which the hardness is the mean of the hardness before heat treatment and after full annealing. The higher the half-softening temperature, the higher the ability to maintain hardness even after severer heat treatment.

Figure 2:

Figure 2: Comparison of properties between

MOFC-HR

and other copper materials (Click the picture to see the enlarged image)

Mitsubishi Materials Group established Our Commitment as "For people, society and the earth, circulating resources for a sustainable future." Going forward, we will continue to create new materials and supply one-of-a-kind high-performance materials and products to realize Our Commitment.

[Related Information]

Press release - September 27, 2021

Development of "MOFC-HR" (HR: Heat Resistance)

Oxygen-Free Copper with the World's Highest Standard in Strength and Heat Resistance

URL: https://www.mmc.co.jp/corporate/en/news/2021/news20211001a.html

Copper & Copper Alloy Business Website - MOFC-HR Series Overview

URL: https://www.mitsubishi-copper.com/en/products/materials/mofchr/

Copper & Copper Alloy Business Website - Multi-gauge Strips Overview

URL: https://www.mitsubishi-copper.com/en/products/processing/shaped/

<Contact details for inquiries>

Corporate Communications Dept.

+81-3-5252-5206