News

October 17, 2025

Mitsubishi Materials Corporation

Developed a New Inorganic Black Pigment "NITRBLACK™ UB-3"

- Achieved 1.5 times higher performance than existing products -

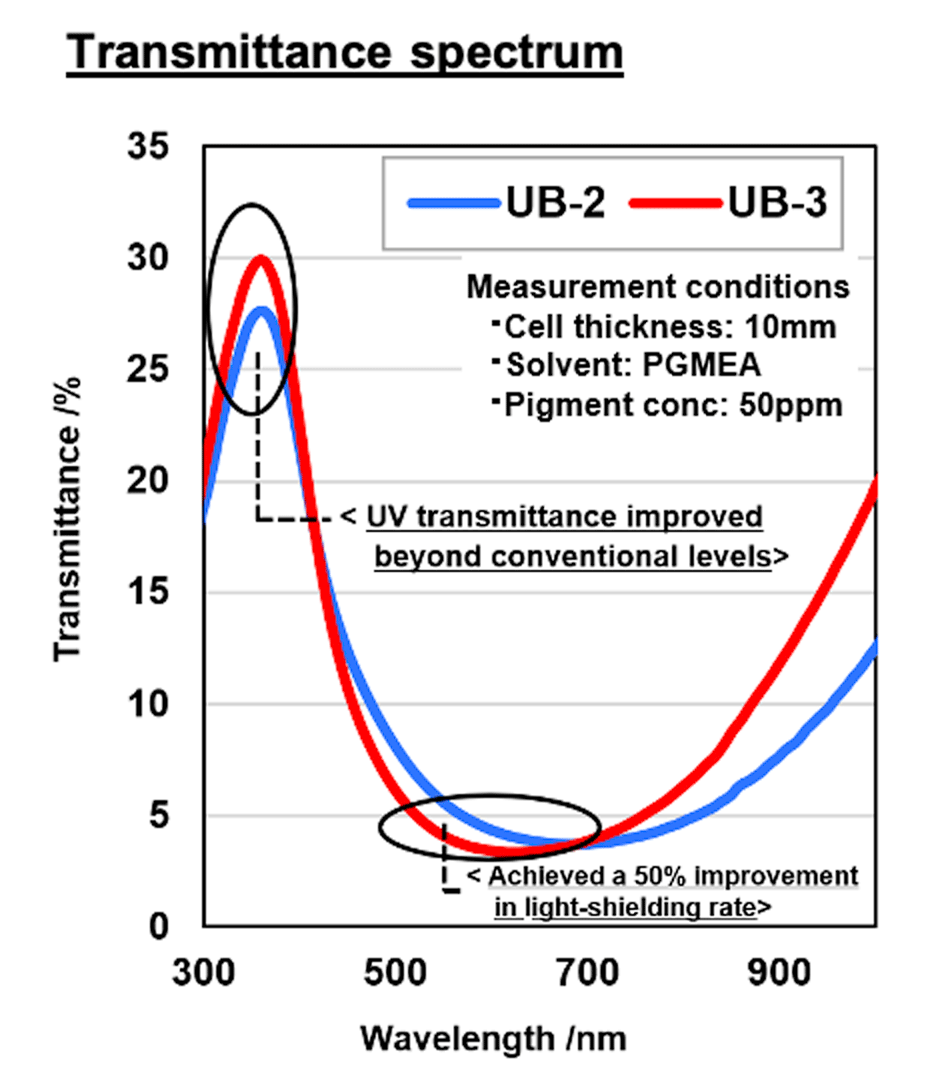

Mitsubishi Materials Corporation ("MMC") and its consolidated subsidiary Mitsubishi Materials Electronic Chemicals Co., Ltd. have developed the ultraviolet ("UV")-transmissive black pigment "NITRBLACK™ (*1) UB-3," which improves the light shielding rate in the visible light range by more than 1.5 times that of NITRBLACK™ UB-2 while maintaining the same level of UV transmittance, by significantly improving the optical performance of existing products.

■Development background and objectives

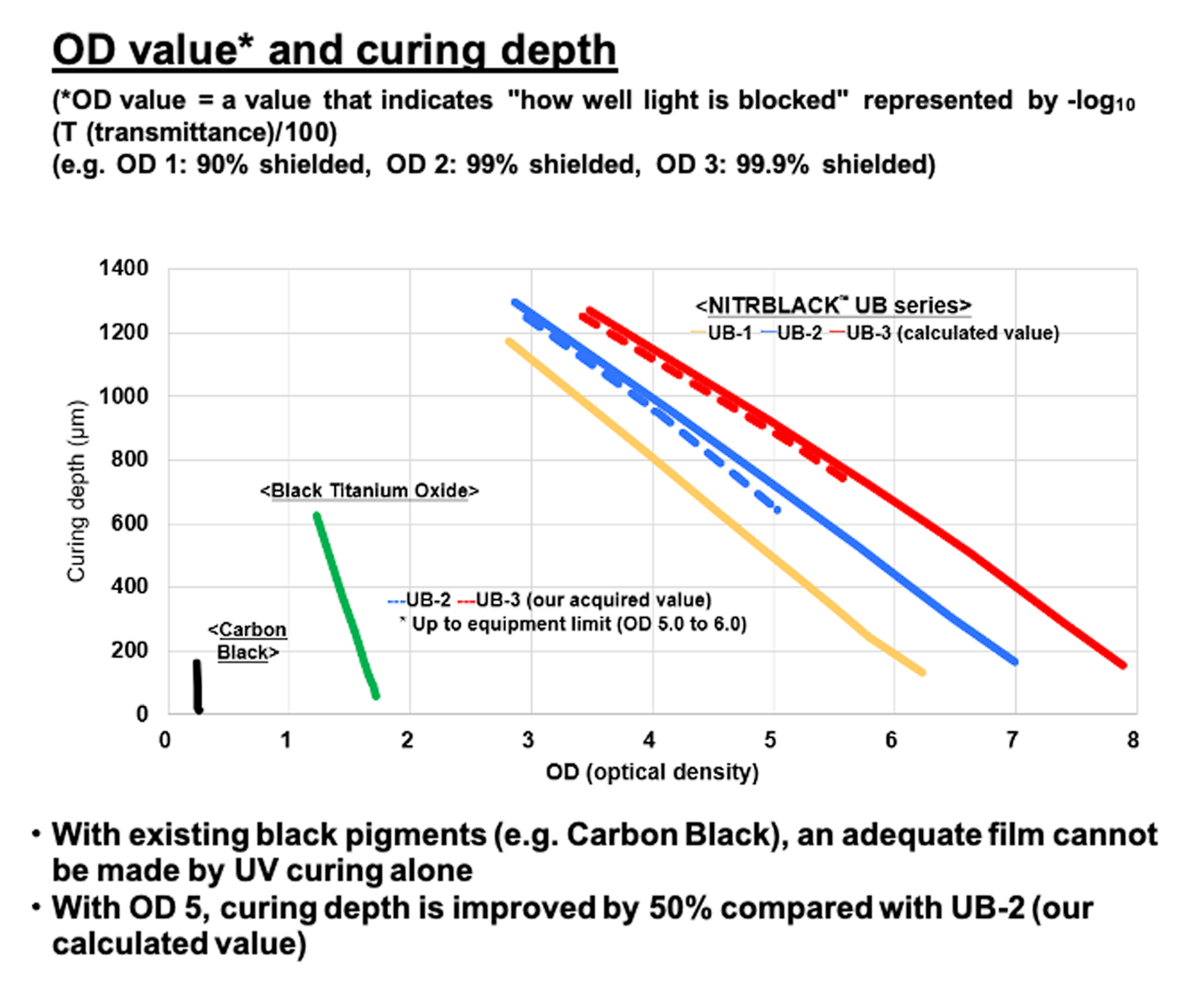

In the field of products such as high-performance displays and optical sensors, black light shielding materials, which are manufactured by thermosetting technology (a technology that uses heat to cause a chemical reaction to cure a material) or light curing technology that uses UV light (a technology that cures a material by reaction to light), are widely used for the purpose of blocking unwanted light from outside or inside devices. Of these technologies, light curing technology has attracted attention in recent years as a next-generation technology that contributes to reducing environmental load due to its many advantages, such as it allows low-temperature processing, its adaptability to microstructures, its excellent curing accuracy, and also its improved productivity through quick curing and energy savings. However, light shielding materials that use conventional black pigments (e.g. Carbon Black and Black Titanium Oxide (*2)) absorb not only light in the visible light range but also ultraviolet light, which is necessary for light curing. This makes it difficult to obtain sufficient blackness by light curing alone, resulting in the issue of requiring a thermosetting process after light curing.

To address this issue, in 2017, MMC used our proprietary nitridation reduction technology (*3) to develop NITRBLACK™ UB-1 ("UB-1"), an inorganic black pigment with high UV transmittance, for the first time in the world. UB-1 is highly regarded as an epoch-making material that achieves the curing of black shielding materials by light curing alone due to it maintaining high transmittance in the UV range while demonstrating excellent light shielding performance in the visible light range. In addition, in 2021, MMC developed "NITRBLACK™ UB-2 ("UB-2")," which offers further improved performance.

- (*1)

- NITRBLACK™, derived from a combination of our proprietary nitrogen reduction technology and the name of a black pigment, is our registered trademark.

- (*2)

- Black Titanium Oxide Product website: https://www.mmc-ec.co.jp/eng/en-product/black-titanium-oxide/

- (*3)

- A technology for transforming a metal or metal compound into a nitride by applying metallurgical methods or by processing in a special environment.

■New product features and applications

In response to requests for further improved performance, MMC has advanced the UB-2 technology to successfully develop the new product "NITRBLACK™ UB-3," which has an improved shielding rate in the visible light range of more than 1.5 times compared with previous products while maintaining the same level of UV transmittance. This product allows the UV irradiation time for light curing to be reduced to less than half that of previous products (according to our test results), enabling light curing of films that are either thicker or have higher blackness, or both.

We anticipate that this product will be increasingly used in displays, optical sensors, etc., which are expected to achieve higher performance in the future, as well as in a wide range of other applications such as light shielding adhesives. Its ability to significantly shorten the UV irradiation time also contributes to shorter working hours in the manufacturing process, improved energy efficiency, and reduced greenhouse gas emissions.

■Form of provision

"NITRBLACK™ UB-3" is available in the form of dispersions (*4), with both solvent-based and low-viscosity monomer-based types (viscosity of several tens of mPa・s). In previous studies, many cases were confirmed where the performance of the "NITRBLACK™ series could not be fully realized when insufficiently dispersed. Provision in the form of a dispersion will enable the performance of "NITRBLACK™ UB-3" to be maximized by more customers and in more applications.

- (*4)

- A liquid substance in which powder is dispersed in the liquid (solvent or monomer).

Dispersion refers to a state in which powder is uniformly distributed in a liquid and particles do not agglomerate and exist in a stable state.

MMC Group has established "For people, society and the earth, circulating resources for a sustainable future" as Our Commitment. Moving forward, we will continue to create innovative materials, deliver one-of-a-kind high-performance products, and work toward realizing Our Commitment by providing optimal solutions tailored to customer needs.

<Contact details for inquiries>

Corporate Communications Dept.

+81-3-5252-5206