News

May 7, 2025

Mitsubishi Materials Corporation

Establishment of a "Post-Stamping Plating" System for PIC plating® of Automotive Connector Terminals

Mitsubishi Materials Corporation ("MMC") has established a "post-stamping plating" (*1) system for PIC plating® (PIC: Precise Interface Control), which reduces the frictional resistance at automotive connector terminal insertion.

As the electrification of automobiles progresses, connectors for electrical components are becoming increasingly multipolar, and this has caused the problem of deterioration of the insertability of connector terminals. In response, MMC focused on the contact structure between connector pin terminals and socket terminals to reduce frictional resistance at terminal insertion and developed PIC plating® in 2014 by applying its proprietary plating technology. Currently, MMC sells strip products ("pre-stamping plated" products) (*2) with PIC plating® applied to various copper alloys.

In recent years, MMC has received many requests from connector manufacturers that use "pre-stamping plated" products asking us to establish a system for "post-stamping plating" (of processed surfaces) so that PIC plating® can also be applied to terminals and other parts that require soldering.

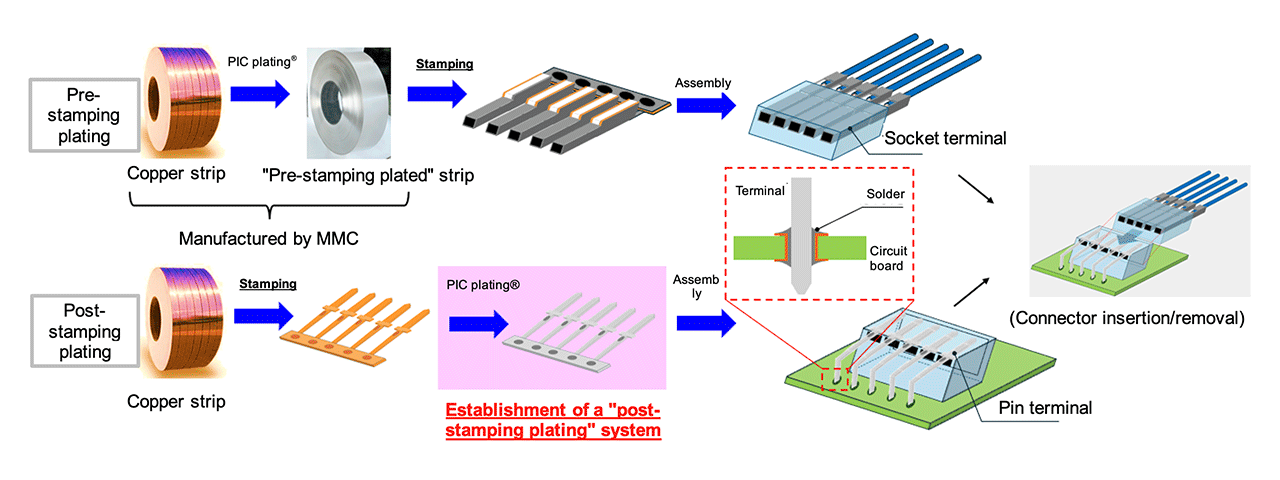

Accordingly, MMC concluded a license agreement with a plating company outside the Group to license the related patents, provide technical know-how, and make other advantages, enabling "post-stamping plating" (four-surface plating (*3)), or application of PIC plating® to terminal materials after stamping working (see Figure 1).

Figure 1: Positioning of PIC plating® in the connector manufacturing process flow (conceptual diagram)

(Click the picture to see the enlarged image)- (*1)

- In the manufacturing process of connector terminals, plating before stamping working of terminals is called "pre-stamping plating" and plating after stamping working is called "post-stamping plating."

- (*2)

- Link to information about strip products with PIC plating® applied : https://www.mitsubishi-copper.com/en/products/plating/pic/

- (*3)

- Stamping working of a strip with PIC plating® applied results in an absence of plating on the processed surfaces (sides) (because only two surfaces, the front and back, are plated), whereas plating after stamping working, which is referred to as "four-surface plating," enables all surfaces including the sides to be plated. Plating all four surfaces improves the reliability of the soldering of the connection between the pin terminals and the circuit board.

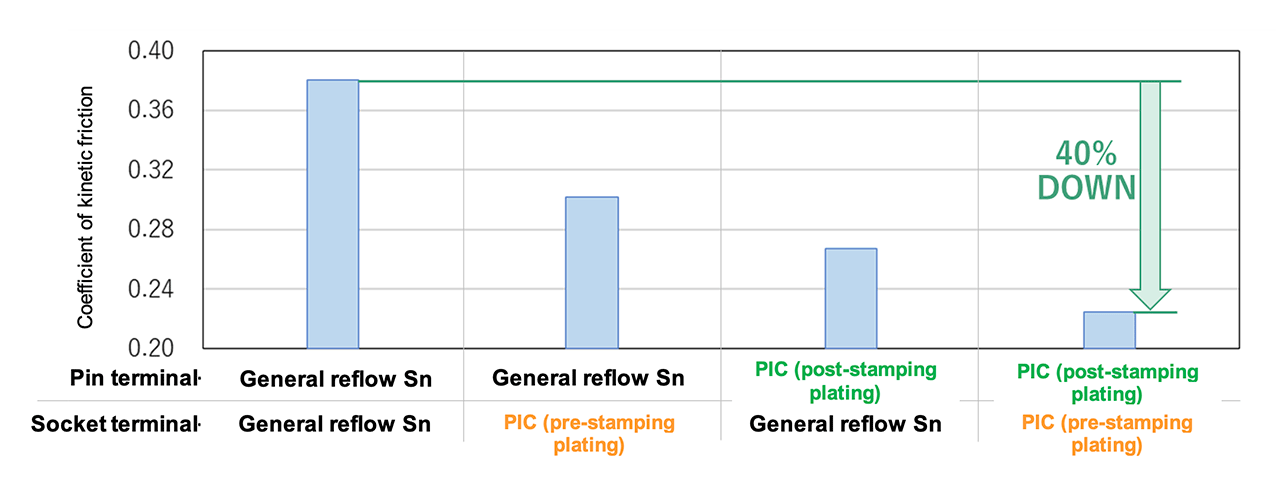

PIC plating® reduces the frictional resistance at terminal insertion, even if used only for either the connector pin terminals or socket terminals. With the new "post-stamping plating" system in place, it is now possible to achieve even better frictional resistance reduction by using PIC plating® for both types of terminals, such as a combination of socket terminals manufactured with a "pre-stamping plated" strip and "post-stamping plated" pin terminals (see Figure 2).

The "post-stamping plating" of PIC plating® contributes to improving the degree of freedom in designing automotive connectors and to reducing the assembly workload.

MMC Group has established Our Commitment as "For people, society and the earth, circulating resources for a sustainable future." We will continue to work towards fulfilling Our Commitment by providing high-performance materials and products.

Figure 2: Comparison of coefficient of kinetic friction (*4) by combination of general reflow tin plating and PIC plating

- (*4)

- Frictional force is generated on the contacting surfaces in the direction that hinders movement when one of the contacting objects is moved. The frictional force generated during the movement of an object in this way is called kinetic friction force. The coefficient of kinetic friction is a dimensionless quantity obtained by dividing the kinetic friction force by the normal force acting on the contacting surface; generally, the smaller coefficient the more slippery the surface.

<Contact details for inquiries>

Corporate Communications Dept.

+81-3-5252-5206