News

March 17, 2025

Tohoku University

Tokyu Corporation

Tokyu Railways Co., Ltd.

Mitsubishi Materials Corporation

R&D on Recycling Used Cables Generated by Railroad Operations to Begin on April 1

- Aiming to establish a system for reducing waste by recycling copper and coating materials -

The four parties—Tohoku University ("Tohoku University"), Tokyu Corporation ("Tokyu"), Tokyu Railways Co., Ltd. ("Tokyu Railways") and Mitsubishi Materials Corporation ("MMC")—will commence research and development on the recycling of used cables generated by railroad operations ("R&D") on Tuesday, April 1, 2025. This R&D has been selected for the FY2025 Environment Research and Technology Development Fund of the Environmental Restoration and Conservation Agency (ERCA) and will be carried out over three years, concluding in March 2028.

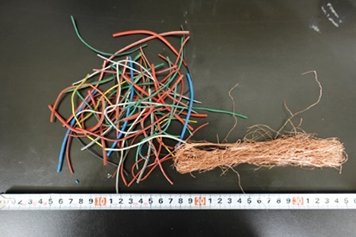

This R&D project uses cables from electrical facilities and signal cables along the tracks of Tokyu Railways, which are currently disposed of, as model cables to develop a combined plastic swelling and ball milling method ("Technology") for separating the cables into copper wires and coating materials. This Technology applies the separation principle of plastic swelling followed by separation through moderate impact from ball milling*, a method that Tohoku University has pioneered and developed in collaboration with MMC. While the cables used in this project have excellent strength to withstand the harsh conditions typical of railroads, the coated wires are thin. Existing coated wire treatment technologies make it difficult to separately sort copper wire and the coating materials to a high purity. As a result, the materials that can be recovered as recyclable resources from used cables are limited. Tokyu Railways generates an average of approximately 10 tons of such used cables per year. We aim to recycle the copper wires and coating materials recovered using this Technology into recycled cables for use in the railroad industry, including Tokyu Railways. Furthermore, we will evaluate the ripple effects on the railroad industry in the future by quantifying the CO2 emission reductions and economic benefits brought about by recycling.

This R&D has been made possible through the collaboration of four parties: Tohoku University, which has pioneered the research and technological development of the combined plastic swelling and ball milling method for coated wires; Tokyu, which formulated its Environmental Vision 2030 in March 2022 to realize a decarbonized and recycling-based society and tackles waste reduction by 10% by 2030; Tokyu Railways, which aims to solve environmental and social issues through activities including new value creation and contribution leveraging its business characteristics to realize a decarbonized and recycling-based society through its railroad business; and MMC, which has advanced smelting and recycling technologies for copper and other nonferrous metals.

Through this R&D, cables from the railroad industry will be made recyclable as recycled cables, which can be applied not only to the railroad industry but also potentially to other industries in the future. Through this effort, we aim to establish a system that reduces and recycles waste as much as possible.

- *

- Separating principle of the combined plastic swelling and ball milling method involves immersing cables in an organic solvent, which causes the coating materials to expand (swell). Impacting the cables in this state with small metal balls or balls made of other materials allows for the separation of copper wires and the coating materials without damaging them. This process is called the "combined plastic swelling and ball milling method."

swollen by an organic solvent

by the combined plastic swelling and ball

milling method

<Contact details for inquiries>

Corporate Communications Dept.

+81-3-5252-5206