News

September 25, 2019

September 2, 2019

Mitsubishi Materials Corporation

Establishment of Smart Factory Promotion Center

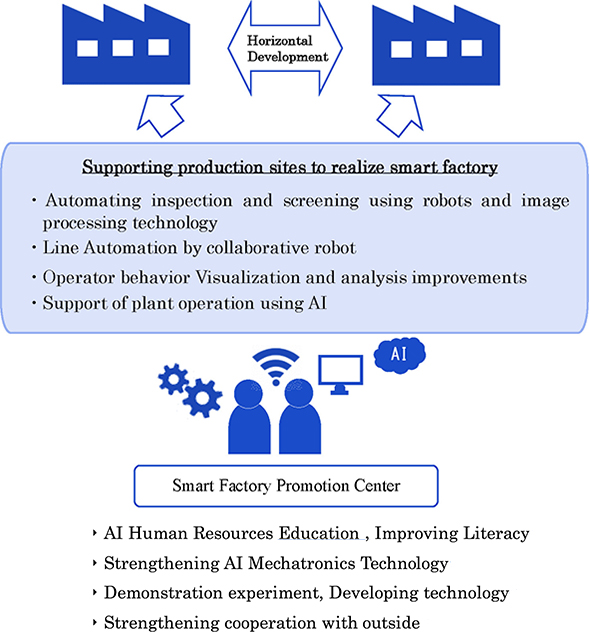

Mitsubishi Materials Corporation (President: Naoki Ono, Capital: 119.4 billion yen; hereinafter the "Company") announced that it has established the Smart Factory Promotion Center (Omiya-ku, Saitama-shi, Saitama-ken; hereinafter the "Center") on September 1, 2019. The Center will facilitate the digitization and automation of the Mitsubishi Materials Group's production sites by using information technology represented by IoT and AI and mechatronics technology.

Surrounded by an increasingly severe business environment in recent years, principally due to diversifying customer needs and the dwindling labor force in Japan, the manufacturing industry is faced with the challenge of delivering better quality and higher production efficiency through digitization and automation. In addition, Mitsubishi Materials Group has been collectively working to advance the automation of its inspection equipment and seeks to strengthen the competitiveness of each business by making its production activities more efficient and sophisticated through the use of large volumes of digital data obtained from these efforts.

The Company has consequently established the Center and assigned engineers specialized in AI to advance sophistication, standardization and horizontal expansion of technologies. Especially for AI technology, the Center aim to involve and train variety human resources including foreigners, exchange human resources actively in Mitsubishi Materials Group. The Center consists of two departments, Advanced System Department which is equipping with IT infrastructure and assisting improvement activity by data analysis, and Advanced Mechatronics Department which is developing product inspection technologies and collaborative robot technologies. Current challenges are as follows:

- AI Failure prediction of critical equipment

- Development of inspection equipment for complex shaped products using robots and image processing technology

- Construction of data collection infrastructure using radio-frequency identification (RFID), regarding information about workers and products

- Improving safety through AI analysis using camera images in production sites

- Automation of visual inspection through AI image analysis

- Supporting for AI plant operation

- Positive exchanging with universities and other external organizations

As described in its long-term management policy, the Mitsubishi Materials Group aims to "become the leading business group committed to creating a sustainable world through materials innovation, using its unique and distinctive technologies, for People, Society and the Earth." The Mitsubishi Materials Group will contribute to society through the creation of safe, quality and productive products that make use of IoT and AI.