News

October 10, 2018

Development of DBA Substrate with Ag Layer that is Useable Under Medium to High-Temperature Conditions in Air

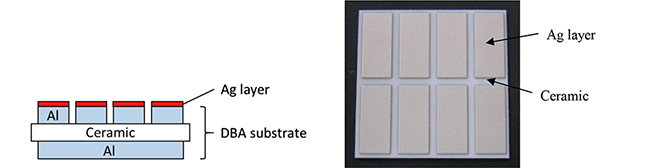

Mitsubishi Materials Corporation (President: Naoki Ono, Capital: 119.4 billion yen) announced today that it has developed a DBA (Direct Bonded Aluminum) substrate*1 with silver (Ag) layer (hereinafter referred to as "the substrate" or "the new product," Figure 1) that can be used under medium- to high-temperature conditions (300-450℃) in air. The new product is intended for use in thermoelectric modules, which are expected to be adopted in the future as an exhaust heat recovery technology for use in cars and factories, and other similar applications.

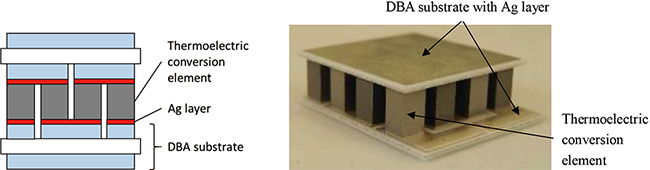

In recent years, thermoelectric conversion technologies are gaining attention because they enable exhaust heat from cars, factories and other sources to be recovered and reused to generate electricity. The thermoelectric modules (Figure 2) used to recover and reuse exhaust heat in cars generate electricity when a temperature difference is applied between the top and bottom of the module, which has substrate layers with copper or silver circuits formed on top of a ceramic base. When using a thermoelectric generator module under the high-temperature conditions (300-400℃) produced by exhaust heat, the circuit metals are prone to oxidation in the air, and there are cases in which the constituent materials (i.e. substrates) and/or thermoelectric conversion elements may be damaged by cracking. This leads to an increase in the internal resistance of the thermoelectric module itself resulting in a decrease in output power, which has been an issue in previous designs.

In response to this issue, Mitsubishi Materials has improved the design by forming a thick Ag layer with strongly adhesive bonding characteristics on top of the DBA substrate's aluminum (Al) circuit. In this way, Mitsubishi Materials has succeeded in the development of a new product that offers both low-resistance Ag circuit-which withstands oxidation at high temperatures-and the stress-relaxation*2 effects of the DBA substrate's aluminum.

By forming a thick Ag layer circuit on top of a DBA substrate, which offers high stress-relaxation effects, the new product prevents oxidation of metal circuit (which causes the module's internal resistance to increase), limits degradation of adhesion of constituent materials and damage due to cracking, and minimizes decreases in generated power output during continuous use in high-temperature environments. Moreover, because the thick Ag layer circuit utilizes pure silver in the top surface layer, when the electrode surface of the semiconductor element used is made of Ag or gold (Au), it is possible to bond the layers directly by solid phase diffusion*3, without the need for any additional bonding material. Bonding the thermoelectric conversion elements directly to the thick Ag layer circuit suppresses increases in the module's internal resistance, thereby achieving higher durability under the high-temperature conditions (450℃) associated with exhaust heat. The direct bonding of semiconductor elements with the new product and its thick Ag layer circuit will contribute to significant improvements in the reliability of thermoelectric modules under high-temperature conditions.

Mitsubishi Materials reported the results of this development project at The 37th Annual International and 16th European Conference on Thermoelectrics (which was held in France in July 2018), and it has since attracted high-levels of interest from overseas, as well as in Japan.

Under its long-term management policy, the Mitsubishi Materials Group aims to "become the leading business group committed to creating a sustainable world through materials innovation, with use of our unique and distinctive technologies, for People, Society and the Earth." Moving forward, the Group will continue to contribute to advancements in the field of electric power devices, through the development of products that make effective use of its unique proprietary technologies.

- *1 DBA substrate

- An abbreviation for Direct Bonded Aluminum substrate; a highly heat-dissipating ceramic insulator substrate with aluminum circuit bonded directly to it.

- *2 Stress relaxation

- A property of materials, whereby an object's response stress is observed to decrease gradually with the passage of time when a certain amount of strain is applied and the object is kept in a strained state for some time.

- *3 Solid phase diffusion

- A process whereby metals can be bonded or welded together using the diffusion of atoms on the bonding surface.

October 3, 2018