News

January 26, 2018

World's First Gold-Tin Alloy Paste Developed that Does Not Require a Washing Process

The Electronic Materials & Components Company of Mitsubishi Materials Corporation (President: Akira Takeuchi; Capital: 119.4 billion yen) has developed the world's first gold-tin (AuSn) alloy paste that does not require a washing process (hereinafter, called "new product") and has started sample shipments.

The gold-tin alloy paste, which is a mixture of gold-tin alloy powder and a binder called "flux", has the following features that are common to the new product and conventional products:

- 1.

- The gold-tin alloy has a high melting point (280℃), which is greater than the typical lead-free solder, and is superior in terms of its high thermal conductivity and post-bonding reliability. It can be used for a variety of applications, including as a material for die bonding*1 in super luminosity type LEDs and for the bonding of air-proof sealing caps*2 for crystal devices*3 and other packages.

- 2.

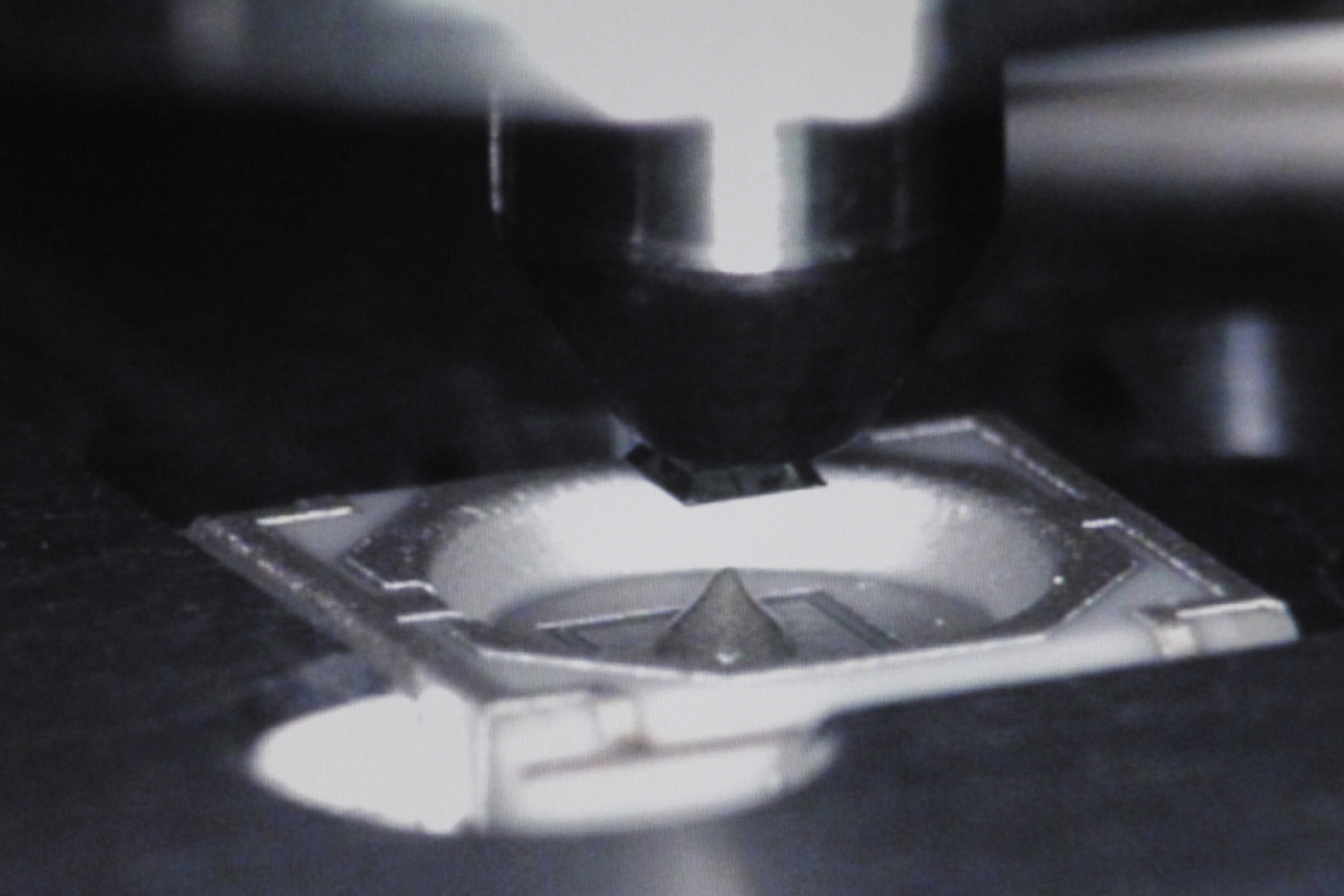

- Because it is in a paste form, it can be used for a wide range of applications, such as screen printing*4, dispenser application*5, pin transfer*6 and other processing methods, and can be promptly used for bonding areas of various shapes.

When using this gold-tin alloy paste for bonding, it is necessary to remove the oxidized film from the powder surface and bonding surface of the gold-tin alloy to improve the wettability (the ability of the melted metal to spread on a solid surface and not be repelled). In the conventional product, a high heat-resistant rosin-based flux is used to remove the oxidized film. However, because this flux is highly thermal-resistant, residue, a cause of corrosion on a bonding surface and other problems, is generated after the thermal process (reflow), which requires a washing process for removal.

Recently, equipments that create an oxygen-reducing atmosphere with formic acid during the thermal process have penetrated the market among customers, and it has become possible to remove oxidized film from the powder surface of the gold-tin alloy. As a result of the successful development of a gold-tin alloy paste using a new flux with a low decomposition temperature, which meets the needs of customers, the newly developed product has the following additional features:

- 1.

- A dramatic decrease in residue from the flux generated after the thermal process, eliminating the need for a washing process.

- 2.

- As the flux decomposes quickly at low temperatures, the reduction effect of formic acid on the removal of oxidized film from the powder surface of the gold-tin alloy is maximized.

Consequently, the bonding reliability is anticipated to improve due to the higher bond rate (percentage of wet area on the gold-tin alloy against the bond area of a loaded object). Meanwhile, the Electronic Materials & Components Company has successfully developed a new product that does not require washing after the thermal process for the first time in the world.

The new product does not use a halogenated activator, which was present in the flux of the conventional product and influenced the stability of the paste. Therefore, another feature is an increase in the guarantee period (pot life) and effective use period.

The new product will not only reduce costs required for special cleaners during the washing and waste disposal process, but is also more environmentally friendly, and will also provide "a sense of joy" to customers, meaning improved productivity with the elimination of the washing process.

The new product was also introduced at NEPCON JAPAN 2018—47th Electronics R&D and Manufacturing Expo, which was held at Tokyo Big Sight from January 17 to 19, 2018. The Electronic Materials & Components Company is actively expanding its applications, especially ones that require high radiation performance and post-bonding reliability, such as super luminosity type LED head lamps and UV-C LED lamps for sterilization, aiming for an annual sales of 2.5 billion yen in 2022.

Our group has a vision of "Becoming the leading business group committed to creating a sustainable world through materials innovation, with use of our unique and distinctive technologies, for People, Society and the Earth." The Electronic Materials & Components Company will continue to contribute to society by developing products that utilize our unique technologies.

- *1.

- Die bonding

A process that bonds a piece of a semiconductor device (die) to a circuit board with adhesive. - *2.

- Air-proof sealing cap

A cap with sufficient airtightness for a package containing electronic parts. - *3.

- Crystal device

A device made with crystal that accurately and stably generates reference signals, which are the base of radio waves for sending and receiving voice data and others. - *4.

- Screen printing

A method that applies paste evenly and flatly at one time on a surface using a mask and squeegee. - *5.

- Dispenser application

A method that dispenses paste from an injector-shaped container using compressed air from the needle-like tip. - *6.

- Pin transfer

Also known as "stamp method" and "stamping method," it is a method that transfers the paste adhered to the pin tips to a desired area.

January 15, 2018