News

June 16, 2016

Mitsubishi Materials Begins Providing Industry 4.0-Conformed 3D CAD Data on Cutting Tools

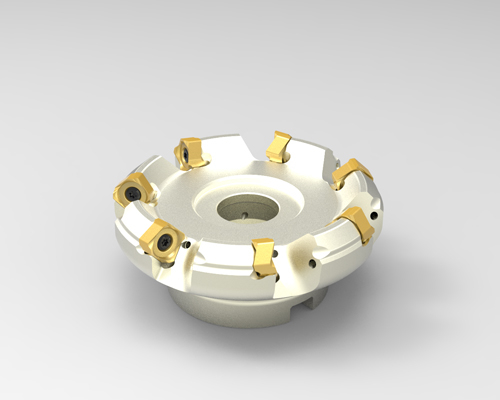

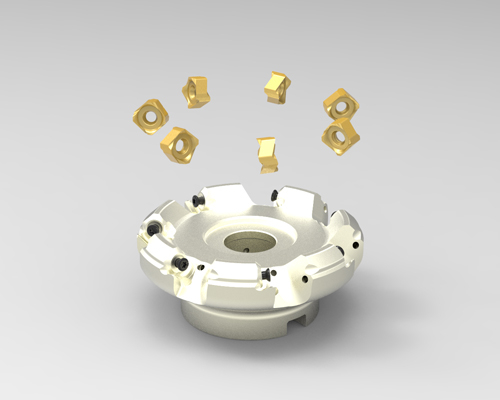

The Mitsubishi Materials Corporation (President: Akira Takeuchi; Capital: 119.4 billion yen; hereinafter "MMC") announced today that its Advanced Materials & Tools Company begin to provide three-dimensional (3D) CAD data on cutting tools that conform to Industry 4.0. By making this data available, MMC seeks to deliver technology information efficiently to customers in Japan and around the world.

Led by the German government and dubbed "the fourth industrial revolution" Industry 4.0 is a strategy for optimizing the practical manufacturing process through the use of information technologies such as the Internet of Things (IoT) and Cyber Physical Systems (CPS) to create networks connecting machines to people or other machines in all fields. Similar to Germany, the government of Japan has also defined the construction of a super-smart society through system networking as one of its national strategies. Under Industry 4.0, one of the most important technologies is that for the standardization of shared data. For data on cutting tools, the data offered must comply with the ISO 13399*1 international standard and the Generic Tool Catalog*2, which both conform to Industry 4.0.

MMC will begin providing 3D CAD data conformed to the aforementioned criteria for the standard models of the cutting tools placed in our product catalog. The data will be made available to customers through the MachiningCloud GmbH*3 website. Customers will be able to download 3D CAD data and use it to simulate cutting before they actually cut with a machining center or a CNC lathe, allowing them to confirm the behavior and develop a processing program in high precision in advance.

Past forms of 3D CAD data on cutting tools did not contain any data on the assembly of the necessary components such as tool holders and inserts. As a result, the worker required complex CAD operation for precise confirmation. MachiningCloud™ possesses the functionality for automatically assembling the necessary components with the use of the assembly data defined in ISO 13399 and the GTC, making it easy for customers to assemble different parts of 3D CAD data on cutting tools needed for simulations. After connecting to the database from their computer or tablet, customers can quickly acquire CAD data on tens of thousands of cutting tools free of charge, by simply selecting the name of the cutting tool product based on the ISO 13399 and GTC standards.

MMC's Advanced Materials & Tools Company takes pride in being a leader among cutting tool manufacturers. We will respond to the demands of society for the efficient provision of manufacturing technology information in line with the "For People, Society and the Earth" commitment stated in MMC's corporate philosophy.

- *1

- ISO 13399

An international standard related to representation and exchange of data on cutting tools that can be interpreted by computer.

This standard covers product information, the methods for preparing databases and regulations on the creation of CAD data on cutting tools. It was established with the aim of defining cutting tools around the world by common parameters and ensuring smooth data communication between systems. - *2

- Generic Tool Catalog (GTC)

A standard for databases of cutting tools that supplements the ISO 13399 standard. It was formulated by a voluntary forum run by cutting tool-related companies around the world.

Website about GTC: http://gtc-tools.com/ - *3

- MachiningCloud GmbH

A company based in Switzerland that provides solutions on cutting processes.

MachiningCloud's website: https://www.machiningcloud.com/

[Advanced Materials & Tools Company website]

http://www.mitsubishicarbide.com/en/

* The website above regularly provides information of cutting tools.

[For inquiries about downloading data, please contact the following:]

Machining Technology Center, Research & Development Div., Advanced Materials & Tools Company

1-297 Kitabukurocho, Omiya-ku, Saitama 330-8508 Japan

+81-(0)48-641-4220

+81-(0)48-641-4159