News

October 7, 2015

Large-Scale Expansion of Solid Carbide Tool Manufacturing Structure by an Indonesian base

Aiming for expanding the Solid Carbide Tool* manufacturing structure, the Mitsubishi Materials Corporation (President: Akira Takeuchi; Capital: 119.4 billion yen: hereinafter, “MMC”) announced today that its Advanced Materials & Tools Company will invest approximately 3.7 billion yen in PT. MMC Metal Fabrication (hereinafter, “MMF”), a carbide tool manufacturing base in Indonesia, to relocate and construct its new “Plant No. 2” in an attempt to strengthen its manufacturing capability, and approximately 400 million yen in the Gifu Plant for installing state-of-the-art drill manufacturing equipment.

Both these facilities are scheduled to commence operations in October 2016.

Solid Carbide Tools such as Solid End Mills and Solid Drills are indispensable for drilling and milling, like grooving and periphery cutting, of metal parts for automobiles and aircraft in the transportation equipment industry and medical devices in precision instrument industries.

While the solid carbide tools market is expanding globally in line with the growth of the industries especially in aircraft, materials for making components are getting diverse and difficultto-cut, such as CFRP, titanium and super heat resistant alloys, to decreasing weight and increasing functionality in recent years. Further, machining shape also tends to be complex. Responding promptly to customer needs and establishing a stable manufacturing structure are mission of MMC's business strategy.

The Advanced Materials & Tools Company, for which Solid Carbide Tools account for approximately 20% of net sales, deliberated its business strategy to cultivate Solid Carbide Tools as another revenue stream in addition to its core “insert” products.

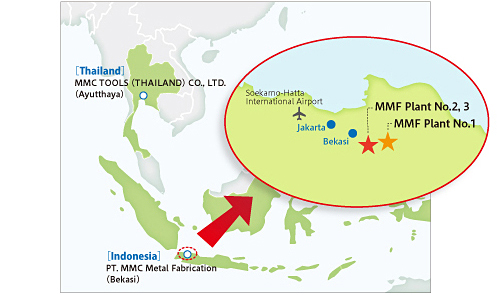

Since MMF's current “Plant No. 2” commenced operations in 2012, it has grown steadily as secondary production base following to the main plant in Thailand for the production of cemented carbide products in Asia area.

MMC decided to expand the MMF and the Gifu Plant manufacturing capability in consideration of (1) MMF's accumulated manufacturing expertise, (2) necessity for fortifying local services in growing ASEAN country markets, and (3) mitigating risks through the dispersion of manufacturing bases.

After relocation, “Plant No. 2 will expand annual Solid End Mill manufacturing capacity to 740,000 units (approximately twice the current capacity) while the new construction will result in a Solid Drill manufacturing line having an annual capacity of 120,000 units. Combined with MMF's expanded capability, the introduction of state-of-the-art equipment at the Gifu Plant is expected to enhance high value-added high-performance products.

Going forward, MMF will focus on general purpose products, while the Gifu and Akashi Plants as the mother factories for Solid Carbide Drills and Solid Carbide End Mills will focus on difficult to machine and other high value-added products, so that MMC will expand its share in the solid carbide tools market.

MMC established “strengthening global competitiveness” as one of the company-wide growth strategy in the Medium-term Management Plan, “Materials Premium 2016”. In that context, MMC will attempt to realize growth through the expansion of overseas manufacturing and sales bases among other business developments, especially in developing countries.

In addition to its existing manufacturing bases in the United States, Spain, Thailand and China, the Advanced Materials & Tools Company is attempting to further strengthen its global competitive capabilities through these manufacturing structure expansions and will realize sustainable growth through the steady acquisition of market share in the expanding solid carbide tools market.

Note: There are two types of drills and end-mills; one product has indexable cutting tool and the other product has fully made by caribide both of cutting edges and shaft. The latter are called Solid Carbide Tools.

Overview of New Factory No. 2 (Expected as of October 2016)

- » Location

- MM2100 Industrial Town, Bekasi City, West Java Province, Republic of Indonesia

- » Business

- Manufacture of solid carbide end mills and solid carbide drills

- » Area

- Land (15,150 ㎡) floors pace (10,200 ㎡)

- » Production capacity

- 740,000 solid end mills and 120,000 solid drills per year

- » Employees

- Approximately 130 people (+ approximately 90 employees compared to August 31, 2015)

MMF New Factory No. 2 Completed Image

MMF New Factory No. 2 Completed Image

【Reference】 PT. MMC Metal Fabrication Overview (As of August 31, 2015)

- » Established

- March 1997

- » Investors

- Mitsubishi Materials Corporation (100%)

- » Representative

- Shigehisa Kondo

- » Head Office

- Jababeka 1 Industrial Estate, West Java Province, Republic of Indonesia

- » Employees

- 299 people (as of August 31, 2015)

(Breakdown: No. 1: 149 people; No. 2: 38 people; No. 3: 87 people; Administrative and others: 25 people) - » Business

- Manufacture and sales of metal welding assemblies, carbide tools and sintered products

- » Main Products

- Plant No. 1: Fabricated products

Plant No. 2: Solid end mills, etc.

Plant No. 3: Sintered products Plant - » Locations

- Plant No. 1 (Located at head office)

Plant No. 2 (Jababeka 3 Industrial Estate, West Java Province, Republic of Indonesia)

Plant No. 3 (MM2100 Industrial Town, Bekasi City, West Java Province, Republic of Indonesia)

Base of cemented carbide business in Southeast Asia