News

December 5, 2013

Development of DBA (Direct Bonded Aluminum) Substrate with Thick Cu for Highly-Functional Insulated Circuit Substrates Used in Next-Generation Power Modules

Mitsubishi Materials Corporation (MMC) (Hiroshi Yao, President and Chief Executive Officer; Paid-in Capital: ¥119.4 billion) has developed “DBA (direct bonded aluminum) substrate with thick Cu” for next-generation power modules by directly bonding copper (Cu) to aluminum (Al) to create a previously unavailable composite material. The result is the creation of a highly functional insulated circuit substrate for use in a broad variety of applications, such as inverters for high-powered hybrid vehicle (HV) motor power control.

【Background and reasons for development】

- In recent years the increased heat generation resulting from increases in device power has lead to demands for reduction of the thermal resistance of insulated circuit substrates used in inverters for power supply control in HVs. Thermal resistance can be reduced through the use of highly-conductive thick copper plate as circuit material, but the thickness of the copper circuit material is limited to 0.8 mm even if silicon nitride, a high-strength ceramic, is used as the insulating substrate. Increasing the thickness of the copper beyond 0.8 mm makes the substrate prone to breakage, making its use in products problematic.

- Production and sale of the DBA substrate, a highly reliable insulated substrate made at our Sanda Plant Shizuoka DBA Center by directly bonding high-purity aluminum to both sides of ceramic substrate, have been directed mainly at HV use applications. Also, our highly developed bonding technologies, which are at the core of DBA substrate technology, were applied by the Central Research Institute in the development of new circuit substrates and bonding material, resulting so far in products such as a heat sink-integrated DBA substrate made through low-temperature bonding of aluminum and ceramic.

- We have now succeeded in developing DBA substrate with thick copper by optimizing the highly reliable bonding technologies and materials composition cultivated through the manufacturing of DBA substrate. We anticipate expanded application of this DBA substrate with thick copper in the future in the automotive and rail sectors, which demand greater reduction of thermal resistance along with high reliability.

【Main characteristics】

- 1)

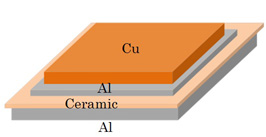

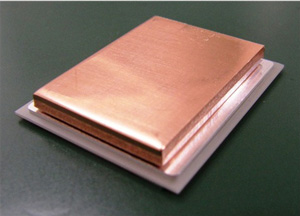

- The construction, which bonds copper directly to the aluminum on both sides of the ceramic substrate, makes possible a copper thickness of 3.0 mm, 4X greater than previous substrates. (Diagrams 1 & 2)

- 2)

- The attached highly-pure aluminum layer serves to further mitigate heat, and achieves high reliability by preventing the ceramic from cracking even under a temperature cycling condition of -40 to 125°C x 3,000 cycles or higher.

- 3)

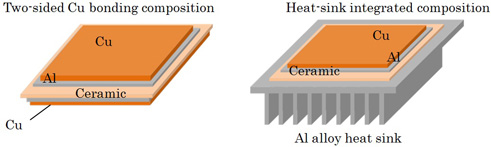

- Aluminum nitride, which has high thermal conductivity, can be used for the ceramic substrate instead of silicon nitride, enabling the realization of a variety of structures, such as that with Cu plate on both sides of a substrate or one integrated with an Al heat sink. (Diagram 3)

“Business advancement in overseas markets, especially emerging markets” and “Exploit synergies from our uniquely integrated businesses to realize the ”Materials Premium“ are the core growth strategies within our “Materials Premium 2013” Medium-Term Management Plan.

Development of this product is an example of “realizing the Materials Premium” by utilizing the Mitsubishi Materials Group's special strengths in our copper and aluminum businesses. We will continue to contribute to the development of the electronic equipment sector by using our unique technologies to create highly-functional insulated circuit substrates for power modules.

Diagram 1 DBA substrate with thick Cu

Diagram 1 DBA substrate with thick Cu

Cu and composition example

Cu and composition example

Diagram 3 Variety of application examples

Diagram 3 Variety of application examples