- Home

- Corporate

- Our Commitment

- Exploring "Our Commitment"

- Mitsubishi Materials' E-Scrap Recycling Business

Recycling the earth's resources

to create a sustainable society

Mitsubishi Materials'

E-Scrap

Recycling Business

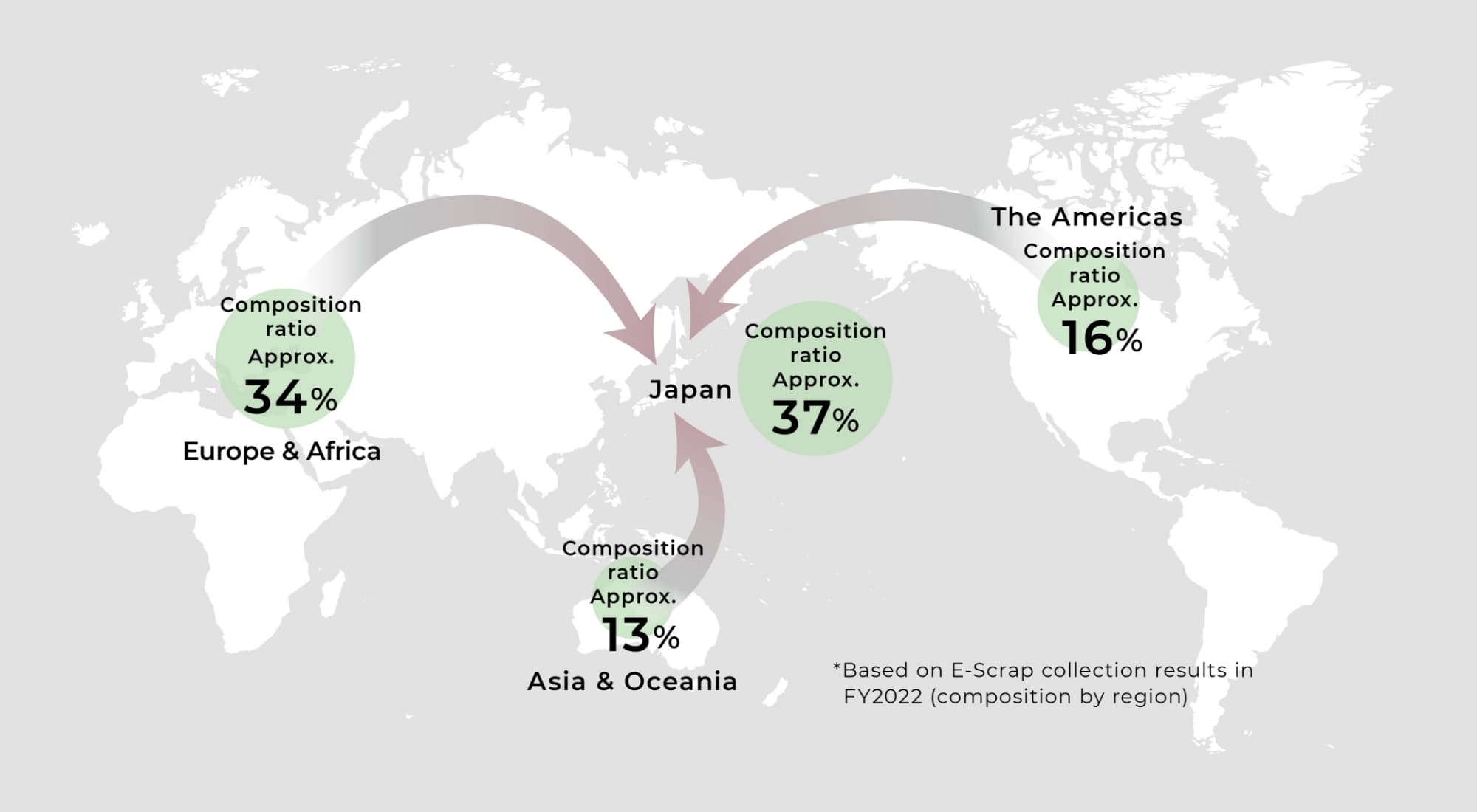

The annual E-Scrap processing capacity of the Mitsubishi Materials Group is approximately 160,000 tons.

This is equivalent to 20% of the approximately 800,000 tons of E-Scrap generated worldwide in a year.

Since the E-Scrap market is expected to expand due to improved recycling rates,

we aim to further expand our processing capacity to approximately 240,000 tons per year by the end of FY2031.

World-class E-Scrap

processing volume

Electronic devices such as home appliances, computers, and smartphones contain valuable metals such as gold, silver, copper, platinum, and palladium. When these electronic devices are recycled, it is possible to recover discarded circuit boards called E-Scrap. E-Scrap is drawing attention as part of urban mining, and the amount handled is only increasing as the recycling rate of electronic devices improves. Mitsubishi Materials collects E-Scrap mainly from Japan, Europe, and North America, and its processing volume is among the highest in the world.

The E-Scrap recycling process

-

Collection

Collecting E-Scrap from

all over the world -

Sampling/analysis

Weighing, inspection,

sampling, analysis -

Smelting

Smelting at Naoshima

Smelter & Refinery

and Onahama Smelter

& Refinery -

Resource recovery

Recycling into copper

and precious

metal ingots

- Weighing

- Inspection

- Sampling

Fair and impartial sampling

Sampling is performed to calculate the amount of valuable metals contained in the E-Scrap. The weighing, inspecting, and

sampling of most of the E-Scrap collected in Europe is performed by MM Metal Recycling BV (hereinafter "MMMR").

Crushed representative samples are flown to Japan and analyzed there to determine the purchase price. By conducting the

entire process of sampling, analysis, purchase price determination, and payment in a fair, impartial, and speedy manner,

we improve customer convenience and build relationships of trust. Sampling is objectively conducted by selecting the

most appropriate method for each of the many different types of E-Scrap.

- Weighing

- Inspecting

- Sampling

- Analysis

- Smelting

Smelted and refined

into high-purity ingots

at Naoshima Smelter & Refinery

and Onahama Smelter

& Refinery

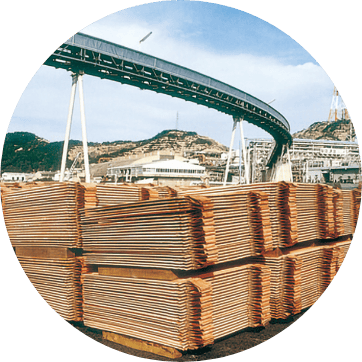

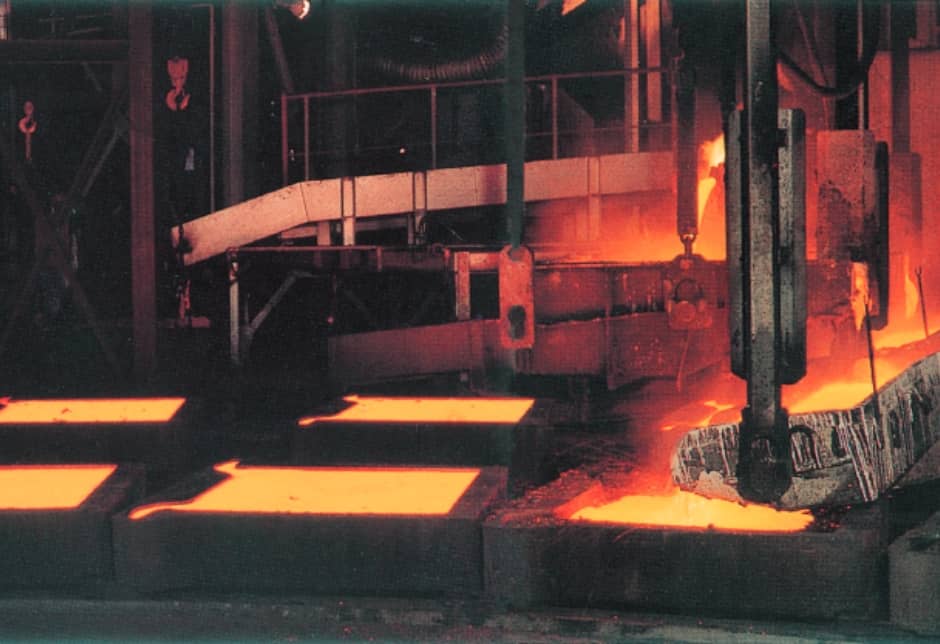

E-Scrap collected from all over the world is smelted at the Group's smelters & recycled into copper and precious metal (gold, silver, platinum, and palladium) ingots.

casting at Naoshima

Smelter & Refinery

Enhancing facilities

and services

to meet customer needs

Harald Wagemaker

General Manager,

MMMR

Expanding MMMR facilities due to

a surge in E-Scrap deliveries

In the past two years, we have experienced tremendous growth in E-Scrap deliveries to MMMR. Since we are accepting more small lots than originally intended, MMMR has enhanced its logistics capabilities, expanded its site, and added new facilities and parking. We have also added space for a third loading dock for containers to comply with environmental regulations. The recycling of non-ferrous metals contributes to a sustainable society. Through our business, we will save raw materials and reduce energy consumption and CO2 emissions, thereby putting our Corporate Philosophy of "For People, Society and the Earth" into practice.

The E-Scrap trading platform MEX

has become even more convenient

In December 2021, Mitsubishi Materials developed and launched MEX (Mitsubishi Materials E-Scrap Exchange), a new

platform for the E-Scrap recycling business.

In May 2022, in response to customer requests, we added an online communication function (confirmation function during

inspection) and a paperless function, allowing customers to check necessary information 24 hours a day.