|

Mitsubishi Shindoh Establishes "ECO BRASS®" Production in China |

Mitsubishi Shindoh, Japan's leading copper and brass producer has established a new company in Qingdao China. The factory will produce ECO BRASS® casting ingots from domestically recycled material. ECO BRASS® is a patented lead-free solution by Mitsubishi for the brass industry. The material is commonly used in water supply fittings and fixtures and meets US EPA standards for antimicrobial properties. ECO BRASS® allows manufactures to comply with stringent lead-free NSF14 Annex G requirements.

NSF14 Annex G was established as a protocol to measure lead in water supply products to meet California's strict lead-free laws and is applicable in Vermont and Maryland. It is anticipated that the US national Safe Drinking Water Act of 1974, signed by President Ford and amended in 1986 by President Reagan, will incorporate NSF14 Annex G into the Act eliminating lead from the national water supply.

ECO BRASS® is a lead-free copper-alloy designed and patented by Mitsubishi, licensed to Chase Brass, Ingot Metals, California Metal X, and Concast in North America, Wieland, Diehl, Otto Fuchs, KME, and Sarbak in Europe. ECO BRASS® rod is designated as copper alloy C69300 and ingot as copper alloy C87850, both conform to ASTM industry standards.

Mitsubishi Shindoh is a wholly owned subsidiary of Mitsubishi Materials Corporation, capitalized at US$10 million, headquartered in Tokyo Japan and led by Mr. Takao Hashida (president). Mr. Hashida reported the recycling factory was needed to satisfy the increasing global demand for lead-free product. The joint venture company was formed in December 2010 and should commence operations by December 2011.

(1) Company Name: Qingdao ECOBRASS Co., Ltd.

(2) Location: Qingdao, Shandong Province, Peoples Republic of China

(3) Capital: US$10 million

(4) Ownership: Mitsubishi Shindoh 70%, OCASTING Holdings Ltd. Hong Kong 30%

(5) Management: Mr. Kenji Kume

(6) Employees: 40

(7) Production Capacity: 1000 ton/month

(8) Expected Startup: December 2011

(9) Product: ECO BRASS® Casting Ingot

Summary of Hong Kong OCASTING Holdings Ltd.

Company: OCASTING HOLDINGS LIMITED

Director: Chen Chen-An

Business: General investment and trade

Products: stainless steel precision cast parts, automobile parts, precision cast part for aircraft jet engines.

|

|

Chase Brass, California Metal-X sign a sublicense agreement for "ECO BRASS®" Ingot in North America |

Montpelier, Ohio, June 24, 2009 - Chase Brass & Copper Company, Inc.

conducted a formal signing of a sub-license agreement with California Metal-X of

Los Angeles, California to produce and sell ECO BRASS® Ingots for

the North American marketplace. Chase Brass has the exclusive license to produce and

sell ECO BRASS® rod and ingot products in the United States, Canada and Mexico. This

sublicense will provide the North American marketplace with another domestic

producer for ECO BRASS® Ingots. "We are excited to have a company

like California Metal-X join the ECO BRASS® family support

network," stated Devin Denner, President of Chase Brass. "They are very well

established and have an excellent reputation for providing value to their

customers. This license will bring further breadth to the supply chain to

support the growing demand for lead-free products."

|

For more information Contact |

|

| Contact: |

Tim Strelitz, President |

| |

CALIFORNIA METAL-X |

| |

366 EAST 58th STREET |

| |

LOS ANGELES, CA 90011 |

| Phone: |

(323) 234-9281 |

| Fax: |

(323) 234-0814 |

| Email: |

tfstrelitz@cmxmetals.com |

| Website: |

www.cmxmetals.com |

|

|

|

Chase Brass, Concast Metal sign a sublicense agreement for "ECO BRASS®" continuous cast rod in North America |

Montpelier, Ohio, August 8, 2006 - Chase Brass & Copper Company, Inc. has entered

into a sublicense agreement with Concast Metal Products Company of Mars,

Pennsylvania to produce and sell ECO BRASS® continuous cast rod, bar and hollow bar

products for the North American marketplace. This sublicense with Concast will provide

North American customers with a domestic source of continuous cast ECO BRASS®

products. Chase Brass has the exclusive license to produce and sell ECO BRASS® rod

and ingot products in the United States, Canada and Mexico.

"Concast will be an excellent partner to produce and market the ECO BRASS® products.

They are the industry leader in continuous cast products in North America, and Chase is

excited to add them to the family of producers who will promote this non-leaded

machinable alloy," stated Devin Denner, Vice President and General Manager of Chase Brass.

|

|

"ECO BRASS®" has been officially added to ASTM |

In May, 2006, "ECO BRASS®" has been officially added to ASTM.

|

|

|

|

|

|

|

|

Chase Brass, Ingot Metal sign deal for "ECO BRASS®" Ingot in North America |

Montpelier, Ohio - On December 9, 2005 Chase Brass & Copper Company, Inc. signed a sub-license

with Ingot Metal Company Limited of Toronto, Ontario to produce and sell ECO BRASS®

Ingots for the North American marketplace.

Chase Brass has the exclusive license to produce and sell ECO BRASS® rod

and ingot products in the United States, Canada and Mexico.

This sublicense will provide the North American marketplace with a domestic producer for ECO BRASS® Ingots.

"We are very excited about the potential for ECO BRASS® in the North American marketplace,"

stated Devin Denner, Vice President and General Manager of Chase Brass. "This license with Ingot Metal Company Limited will

allow us to aggressively market and produce ECO BRASS® Ingots for North American casting manufacturers."

|

For more information Contact |

|

| Contact: |

David Shore, Sales Manager |

| |

INGOT METAL COMPANY LIMITED |

| |

111 FENMAR DRIVE |

| |

TORONTO, ONTARIO, M9L 1M3 |

| Phone: |

(800) 567-7774 |

| Fax: |

(416) 749-1371 |

| Email: |

dshore@ingot.ca |

| Website: |

www.ingot.ca/ecobrass |

|

|

|

Chase Brass & Copper and Sambo Shindoh

sign license agreement for lead-free "ECO BRASS®" |

Chase Brass & Copper obtained ECO BRASS® exclusive rights for North America

On April 28, 2005, Sambo Shindoh Co., Ltd. (Head Office: Sakai-City,

Osaka, Japan, President: Takao Hashida) and Chase Brass & Copper Co., Inc.

(Head office: Montpelier, Ohio) signed a license agreement for lead-free

ECO BRASS®. Chase Brass obtained exclusive rights for the

production and sale of ECO BRASS® rod and ingot in North America.

ECO BRASS® is a lead-free brass material commercially developed

by Sambo Shindoh Co., Ltd., a leading Japanese manufacturer of brass mill products.

Chase Brass & Copper Company, Inc., a wholly-owned subsidiary of Olin Corporation,

is the largest brass rod manufacturer in North America. The company selected

ECO BRASS® to meet the needs of the marketplace requesting a lead-free brass

alternative. This lead-free alloy has physical and mechanical properties that

provide excellent strength and corrosion resistance characteristics while still

maintaining good machinability.

This partnership with Chase Brass finalizes Sambo's strategy to establish marketing

and sales efforts globally, including Asia, Europe and North America.

|

|

|

Ohki Shindo and Sambo Copper sign license

agreement for "ECO BRASS®" |

On March 23, 2005, Ohki Shindo (Head office: Tokyo, Japan) and

Sambo Copper signed a license agreement on a non-exclusive basis for the

alloy and trademark "ECO BRASS®", lead-free brass, within

the territory of Japan.

Ohki Shindo is a leading manufacturer of brass rod in Kanto area with a monthly

production of 2,500-2,700 tons. They also supply Bi added lead-free brass.

By adding "ECO BRASS®", Si added lead-free brass with high strength

and excellent stress corrosion cracking resistance to their products lineup,

they will advance customer development further.

By grant of the license to Ohki Shindo, the "ECO BRASS®" family now consists of four companies, including Sambo Copper, Dowa Mining and Nippon Shindo. We plan to expand the "ECO BRASS®" family further in the future.

|

|

Nippon Shindo and Sambo Copper sign

license agreement for "ECO BRASS®" |

On March 5, 2004, Nippon Shindo (Head office: Osaka, Japan)

and Sambo Copper signed a license agreement on a non-exclusive basis for the alloy

and trademark "ECO BRASS®", lead-free brass, within the territory of Japan.

In Japan, this is the second agreement after signing with Dowa Mining in December 2003.

Nippon Shindo also supplies Bi added lead-free brass. With the license agreement for "ECO BRASS

®", Si added lead-free brass, Nippon Shindo will produce and sell "ECO BRASS®" to meet customer's needs.

|

"ECO BRASS®" is

officially registered by the CDA as UNS Alloy No. C69300 and C87850 |

The Copper Development Association (CDA), Technical Service

and Standards Advisor Committee, in its December 10, 2003 meeting approved the registration of

ECO BRASS® as UNS Alloy Nos. C69300 and C87850.

The compositions and associated data are now added to the Copper Page Website, properties Section.

C69300 is for Wrought Copper Alloy and C87850 is for Casting Alloy.

ECO BRASS® is a new lead-free Copper alloy leading the way towards a Lead-Free global standard.

The following icon is linked to theCDA Copper Page Website Properties Section.

http://www.copper.org/resources/properties/db/CDAPropertiesSelectionServlet.jsp

Chemical Composition, Percent Maximum

(Unless shown as a Range or Minimum) |

|

C69300 | C87850 |

| Copper(incl Ag) | 73.0 - 77.0 (x) | 74.0 - 78.0 |

| Lead | 0.10 | 0.10 |

| Iron | 0.10 | 0.10 |

| Tin | 0.20 | 0.30 |

| Zinc | Rem. | Rem. |

| Nickel(incl Co) | 0.10 | 0.20 |

| Manganese | 0.10 | 0.10 |

| Silicon | 2.7 - 3.4 | 2.7 - 3.4 |

| Phosphorus | 0.04 - 0.15 | 0.05 - 0.20 |

| Antimony | -- | 0.10 |

| | (x) Cu + Sum of Named Elements, 99.5% min |

|

|

Dowa Minig and

Sambo Copper sign license agreement for "ECO BRASS®" |

On December 22, 2003, Dowa Mining (Head office: Tokyo,Japan. President: Hirokazu Yoshikawa)

and Sambo Copper signed a license agreement on a non-exclusive basis for the alloy and trademark "ECOBRASS", lead-free copper, within the territory of Japan.

Sambo Copper has already concluded a license agreement for "ECOBRASS" with Wieland-Werke AG (Head office: Ulm, Germany) on November 1, 2003 within the territory of Europe. However, this is the first agreement within the domestic market.

Sambo Copper has a plan to grant the same License Agreements to more companies both in Japan and foreign countries as part of it's strategy to establish "ECOBRASS" as the global standard for Lead-Free brass.

Dowa Mining also supplies Bi added lead-free brass. By adding "®" to their products lineup, they will be able to widely comply with customer's lead-free needs and expand sales of lead-free brass.

The production of "ECO BRASS®" will eventually be carried out by their 100% owned subsidiary, Shin Nihon Brass (Head office: Asahi-city, President: Yasuharu Fujita). In the initial stages, they will buy rod from Sambo Copper for resale or processing.

|

|

The Japan Copper and Brass Association

establishes a Technical Standard for Lead-Free Brass |

Growing environmental problems has increased

the demand for Lead-Free Brass at various industries. Reflecting these demands, the Japan Copper and

Brass Association established a Technical Standard for Lead-Free Brass (JCBA T204),

Which includes 4 Bi added alloys and 2 Si added alloys.

These 6 lead-free alloys meet the new Japanese drinking water regulations enforced

from April 1, 2003. That requirement stipulates the amount of lead leaching from water supply devices

should be less than 0.01mg/L. In addition to being lead-free, these materials have good machinability

and forgeability. The Japan Copper and Brass Association will work to promote this technical standard

to a JIS standard.

"ECO BRASS®" is registered as alloy numbers C6931 and C6932. ECO BRASS® has high strength equal to stainless steel, good abrasion resistance and solves the problems of dezincification corrosion and stress corrosion cracking both, which are characteristic problems of traditional brass.

Alloys and Chemical composition

| AlloyNo. | Chemical composition (%) |

| Cu | Bi | Si | Sn | P | Pb | Zn | Fe | Others |

| C6801 | 57.0~64.0 | 0.5~4.0 | - | 0.2~2.5 | 0.2Max. | 0.01Max. | Rem. | 0.5Max. | |

| C6802 | 57.0~64.0 | 0.5~4.0 | - | 0.2~2.5 | 0.2Max. | 0.01<

0.1Max. | Rem. | 0.7Max. | |

| C6803 | 57.0~64.0 | 0.5~4.0 | - | 0.2~2.5 | 0.2Max. | 0.01Max. | Rem. | 0.5Max. | Se+Al+Sb+Te

0.02~0.6 |

| C6804 | 57.0~64.0 | 0.5~4.0 | - | 0.2~2.5 | 0.2Max. | 0.01<

0.1Max. | Rem. | 0.7Max. | Se+Al+Sb+Te

0.02~0.6 |

| C6931 | 69.0~80.0 | - | 2.0~4.0 | 0.2Max. | 0.02~0.15 | 0.01Max. | Rem. | 0.3Max. | Mg

0.1Max. |

| C6932 | 69.0~80.0 | - | 2.0~4.0 | - | 0.02~0.15 | 0.01<

0.1Max. | Rem. | 0.3Max. | Mg

0.1Max. |

|

|

Wieland-Werke

and Sambo Copper sign license agreement for Europe |

Sambo Shindoh Co., Ltd.

(head office: Sakai City, Osaka, Japan. president: Mr. Tosiki Takeiri)

announces that Sambo entered into a license agreement for the alloy and

trademark "ECOBRASS" with

Wieland-Werke AG (head office: Ulm, Germany).

Sambo grants on an exclusive basis a lead-free copper alloy

under the trademark "ECOBRASS" to Wieland within the territory of Europe.

Sambo has already acquired CDA alloy number for "ECOBRASS"

and has granted patents for this alloy

in the U.S.A., Australia, Taiwan, and South Korea.

Sambo has an European patent application for

"ECOBRASS" and expects that it will be granted soon.

This License Agreement is part of the strategy of

Sambo to establish "ECOBRASS" as the global standard of Lead-Free brass

in the near future.

Wieland is a major producer of copper and copper alloys in Europe and has a capacity of 500,000 t/year

worldwide.

"ECOBRASS" is one of the leading Lead-Free brass in the world. Next year,

Wieland will start production and sales of "ECOBRASS" in Europe based on this License Agreement.

Sambo and Wieland also agreed to develop the market for "ECOBRASS" worldwide.

Sambo believes this as a first step toward overseas presence of "ECOBRASS".

|

| Wieland-Werke AG : http://www.wieland.de/internet/ |

|

"ECO BRASS®" US patent received July 2002, prepares for CDA and

ASTM registrations |

| We received patent number 6413330

for ECO BRASS® entitled "Lead-free

free cutting copper alloys" in

the United States on July 2, 2002. |

Patent No.6,413,330 (Click

for Enlargement) |

Patent Description (Click

for Enlargement) |

| Following the US patent,

application for an alloy number was sent to the Copper

Development Association (CDA). The CDA number should be

registered by end of 2002. ECO BRASS® rod will be

registered as C69300 and the castings will be registered

as C99200. We also are applying to the American Society

for Testing and Materials (ASTM) for a Standard listing.

|

ECO BRASS® Patent

Status

| Country |

Patent

Date |

Patent

Number |

| USA |

2002/07/02 |

6,413,330 |

| Australia |

2001/12/30 |

738301 |

| Australia |

2002/06/06 |

744335 |

| Taiwan |

2001/06/14 |

127567 |

|

| |

"ECO BRASS®" complies with new Japanese lead leaching standard of

0.005mg/L set to be enforced April 1, 2004 |

|

The Japanese Ministry of Health, labor

and Welfare will revise the drinking water law on April

1, 2004. With the new law, lead content in drinking

water will be decreased to a maximum of 0.01mg/L from a

maximum of 0.05mg/L. The amount of lead leaching from

water supplying devices will also be reduced to one

fifth of the current standard. ECO BRASS® contains less

than 0.1% lead and drinking water supplying devices made

from ECO BRASS® have a lead leaching amount of less than

0.005mg/L. By using ECO BRASS® faucet, valve, fitting

makers and other drinking water supply device makers can

easily comply with the new standard. |

Lead was not detected in the lead

leaching test performed by the Japan Food Research

Laboratories. (detection limit 0.005mg/L) |

Lead leaching comparative graph

|

Sample chemical composition & test

results

Sample: Cast & machined

ECO BRASS®

(wt%)

|

Cu

|

Si

|

Pb

|

Zn

|

| (1)

0.03% Pb ECO BRASS® |

75.56

|

3.05

|

0.036

|

Rem

|

| (2)

0.1% Pb ECO BRASS® |

75.34

|

3.10

|

0.107

|

Rem

|

|

Test Results

|

Pb

Leaching (mg/L)

|

|

(1) 0.03% Pb ECO BRASS® |

Undetectable*

|

|

(2) 0.1% Pb ECO BRASS® |

Undetectable*

|

|

(3) 2% Pb CAC203 |

0.20

|

|

(4) 5% Pb CAC406 |

0.39

|

|

* Detection limit 0.005mg/L |

|

Test Method: JIS S 3200-7:1997

(no surface conditioning)

Tested by: The Japan Food Research Laboratories

Test results published: March 10, 2000

Document control number: 200021557-001,002,006,007 |

|

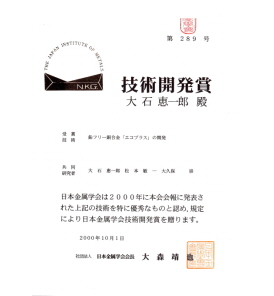

"ECO BRASS®"

receives "New Technical Innovation" award

from the Japan Institute of Metals |

|

ECO BRASS® received the "New

Technical Innovation" award from the Japan

Institute of Metals November 1, 2000. This award is

given to those who create new products or technical

developments that are considered innovative. (Japanese

text)

|

| Click Image for an

Enlargement |

"ECO BRASS®"

water meter certified by the Japan Water Works

Association (JWWA) |

Kimmon Co. Ltd. Water Meter |

An ECO BRASS® water meter produced by

Kimmon Co., Ltd. was the first lead-free water

meter certified by the Japan Water Works Association. |

| |

|

|