|

|

| High

Strength Equivalent to Stainless Steel |

|

|

|

| The strength (tensile strength and yield strength) of

ECO BRASS is about 1.4 times as great as that of C3604

and C3771, equivalent to that of C6782 with the highest

strength among wrought copper alloys and the same as

stainless steel SUS304/SUS303. |

|

Tensile Strength

|

Yield Strength

|

|

|

|

|

| Excellent

De-Zincification Corrosion Resistance |

|

|

|

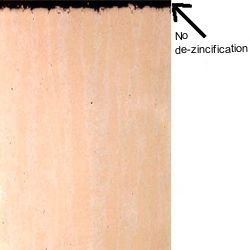

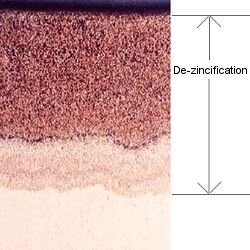

| ECO BRASS has excellent dezincification corrosion

resistance and is the same as C83600 (BC6). Forgings and

castings of ECO BRASS have excellent dezincification

corrosion resistance without heat treatment after

forging and casting. |

|

Corrosion depth after

ISO6509

dezincification corrosion test

|

|

|

|

|

EcoBrass

|

C3604

|

Maximum corrosion depth of C3604 and C3771 is almost

0.04" (1.0mm), but the corrosion depth of ECO BRASS

is almost zero, the same as *UR or BC6.

*UR is Mitsubishi Shindoh's "Ultra Restraint"

brass series.

|

|

|

| Excellent

Stress Corrosion Cracking Resistance |

|

|

|

| Stress corrosion cracking is a common problem with

traditional brass materials. The photo shows an

example of stress corrosion in alloy C3604.

ECO BRASS contains 21% zinc, much lower than

traditional brass materials, and an addition of 3%

silicon, which suppresses stress corrosion cracking.

In each accelerating test, JIS A, CES A and

Mattsson's, ECO BRASS sensitivity to stress corrosion

cracking was less than 1/30 of that of C3604 or C3771.

|

|

Stress Corrosion in

C3604

|

|

Enlargement

|

|

|

|

|

Test pieces are made by cutting an internal thread on

hexagonal bars. The test is performed with 1500 kgf cm

torque loaded.

JIS A method: Soaking in an atmosphere of NH4OH

aqueous solution (concentration: not less than 11.8%)

for 2 hours at room temperature and identify cracks by

visual observation.

|

|

|

| Excellent

Warm Brittleness Cracking Resistance |

|

|

|

| Traditional free-cutting brass contains lead, which

has a low melting point of 572oF (300°C). Because of

the lead content, the impact value rapidly decreases.

When the material is worked, heat is generated and

cracking occurs. This phenomenon is called warm

brittleness cracking. ECO BRASS contains no lead and

does not suffer from warm brittleness cracking. |

|

|