| The electron micrograph photo shows the microstructure

cross-sections of ECO BRASS and C36000 rod. Lead

contained in free cutting brass rod does not form as a

solid solution in the matrix consisting of α-phase and

β-phase, but exists as dispersed particles visible as

white specks in the C36000 image. These dispersed lead

particles act as chip breakers during machine work. The

microstructure of ECO BRASS rod consists of silicon rich

κ-phase (representative composition: Cu8Zn2Si),

γ-phase (representative composition: Cu4ZnSi)

and α-phase. κ-phase and γ-phase which are formed by

the silicon additive, function as the chip breakers.

|

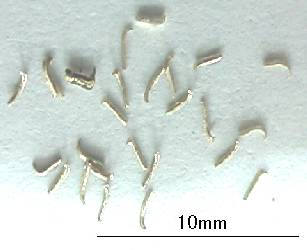

| The chips of ECO BRASS are small and do not twine

around the work or tools, allowing trouble free

machining, even with high-speed automatic operations.

ECO BRASS provides good machinability without lead and

has a smooth surface finish that can not be obtained

with traditional brass, bronze, SUS304, SUS303 or free

cutting steel SUM23L.

|

|

EcoBrass Chips

|

Brass Rod (C3604) Chips

|

|

|

|

|

| Excellent

Hot Forgeability |

|

|

|

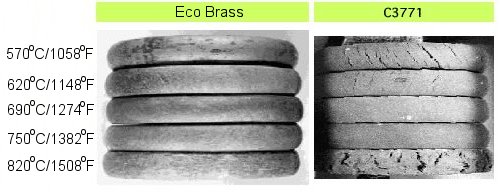

| The hot compression tests in the photo were made in

our laboratory. ECO BRASS has no cracks at any

temperature and shows greater deformability than C3771.

|

|

Hot compression testing procedure

|

| The melting temperature of ECO BRASS is 234oF

(130oC) lower than that of C83600 and the fluidity of

ECO BRASS is better than that of C83600. ECO BRASS is also

suitable as a casting alloy.

|

|

Alloy

|

Melting Point (oF)

|

Melting Point (oC)

|

|

EcoBrass

|

1,616

|

|

|

C3604

|

1,652

|

|

|

CAC406 (BC6)

|

1,850

|

|

|

We evaluated the fluidity of ECO BRASS with a spiral

fluidity tester. Fluidity was evaluated by measuring the

distance the molten metal flows into a spiral metallic

mold. The fluidity of ECO BRASS was found to be better

than that of CAC406. The table and photos show that ECO

BRASS as a molten metal flows better than CAC406 even

if its pouring temperature is 212oF (100oC)

lower than that of CAC406.

|

|

Alloy

|

Temperature oF

|

Distance (inch)

|

Temperature oC

|

Distance (mm)

|

|

EcoBrass

|

2,012

|

12.2

|

1,100

|

310

|

|

2,102

|

14.2

|

1,150

|

360

|

|

CAC406 (BC6C)

|

2,192

|

8.3

|

1,200

|

210

|

|

|

|

EcoBrass

|

CAC406 (BC6C)

|

|

|

|

|