- Home

- Products & Business

- Environment and Energy

- Non-ferrous Metal Recycling Facility

Non-ferrous Metal Recycling Facility

Features

Establish non-polluting system by Mitsubishi Process

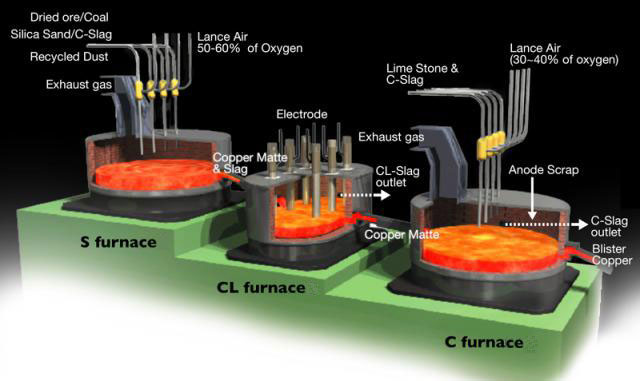

Conventional copper smelting employs many different types of stand-alone furnaces: a flash furnace or reverberatory furnace, multiple converting furnaces, and anode furnaces. Molten metal at temperatures typically over 1200°C istransferred between furnaces by using a large ladle and transported by crane in batches.

The Mitsubishi Process for continuous copper smelting uses launders to transport metal between the smelting furnace, slag cleaning furnace and converting furnace, and finally to the anode furnaces. As a result, we have succeeded in creating a process that is continuous rather than batch-based. This approach allows facilities to be more compact, and reduces energy and operation costs. The conventional method leaked sulfur dioxide gas when molten metal was transferred between furnaces using a ladle. The use of launders made the need for ladles obsolete, resulting in a non-polluting system.

Contact

Metals Company, Resource Circulation Div.

TEL:+81-3-5252-5218

FAX:+81-3-5252-5317

Related Websites

Naoshima Smelter & Refinery

http://www.mmc.co.jp/naoshima/process/mitsubishiprocess.html