- Home

- Corporate

- Our Commitment

- Exploring "Our Commitment"

- Leveraging our strengths in smelting and home appliance recycling

To deliver limited metal resources to society

Leveraging our strengths

in smelting and

home

appliance recycling

Mitsubishi Materials will establish a metal resource recycling system by integrating its disassembling

and sorting technologies from home appliance recycling with its expertise and experience in separating

and recovering valuable metals acquired through smelting.

As part of the FY2031 Strategy, we will prioritize the recycling of metal resources.

By expanding both the scope and scale of recycling operations, as well as the regions where it is implemented,

we aim to achieve growth across the entire value chain.

Mitsubishi Materials operates in two types of businesses: venous and arterial.

Venous businesses involve collecting and recycling used products for reuse,

while arterial businesses focus on product generation. The flow of goods within these businesses

can be compared to the circulation of blood.

In venous businesses, where used and discarded products are fed into the recycling process

and reused as raw materials or materials, Mitsubishi Materials' strength lies in its technologies cultivated

over many years of smelting and home appliance recycling.

Securing natural resources

Continuous investment in mines

to secure 500,000 tons

of copper concentrates

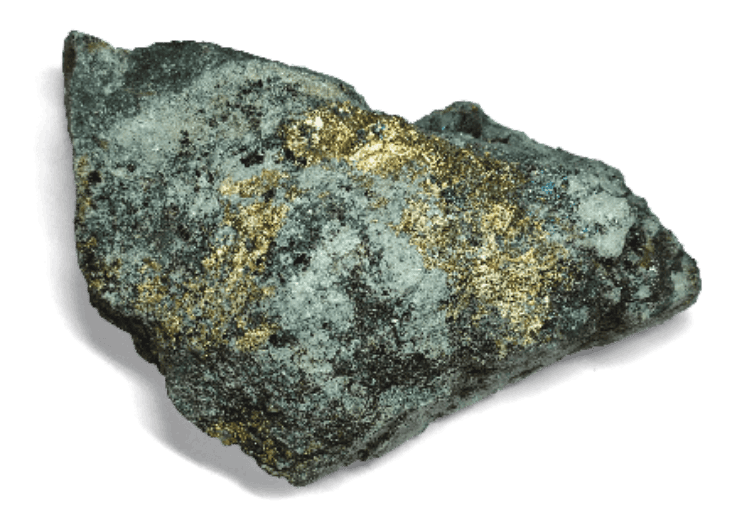

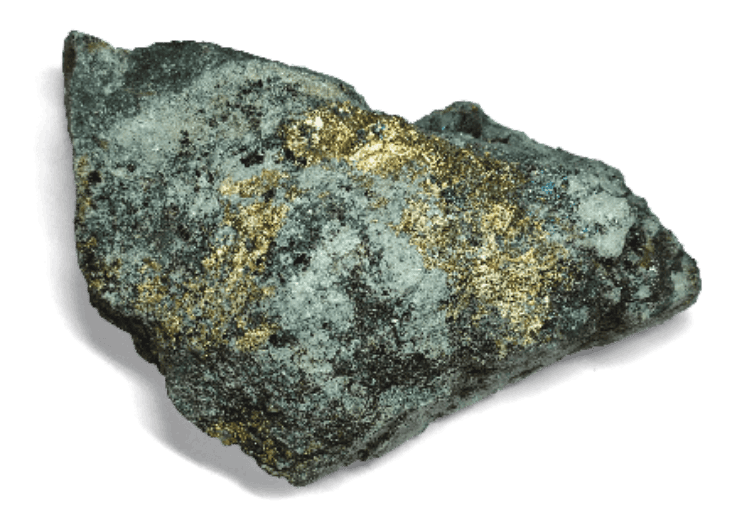

We secure metal resources from mines and deliver them to society. Mitsubishi Materials has invested in overseas copper

mines to ensure stable procurement of clean copper concentrates. Currently, Mitsubishi Materials holds interests in four

operational mines: Copper Mountain Mine in Canada, and Mantoverde Mine, Los Pelambres Mine, and Escondida Mine in Chile,

and we secure approximately 150,000 tons of copper concentrates annually from these mines. While mining development has

a long history, many easily accessible mining locations have already been exploited, resulting in the challenge of

increasing production costs for mines. Moreover, there is a shortage of supply for rare metals like cobalt, despite the

growing demand for them.

To address these concerns, Mitsubishi Materials has set a target of increasing the volume of secured copper concentrate

from the current 150,000 tons to over 500,000 tons by FY2030. This will be achieved through participation in new

medium-scale copper mines and other measures. This target represents approximately 30% of the copper concentrate volume

processed at the Naoshima and Onahama Smelters and Refineries.

Recovering scarce resources with

the power of technological development

We solve resource challenges through the power of technological development. In 2020, Mitsubishi Materials established

the Mining & Metallurgy Laboratories, expanding its existing smelting technology development base to include resource

technology development functions. We are strengthening technological development to ensure superior and stable

procurement of clean copper concentrates.

One of the challenges faced by existing operational mines is the decrease in ore grade (metal content) due to deeper

mining and the increasing impurities within copper concentrates. In response, Mitsubishi Materials has bolstered its

resource technologies through developments such as impurity removal techniques. This has enabled the establishment of a

comprehensive development framework that spans from metallic mineral analysis to metal recycling technologies, allowing

Mitsubishi Materials to swiftly tackle diverse technological challenges related to metallic minerals.

in which Mitsubishi Materials holds interests

Continuous investment in mines

to secure 500,000 tons

of copper concentrates

We secure metal resources from mines and deliver them to society. Mitsubishi Materials has invested in overseas copper

mines to ensure stable procurement of clean copper concentrates. Currently, Mitsubishi Materials holds interests in four

operational mines: Copper Mountain Mine in Canada, and Mantoverde Mine, Los Pelambres Mine, and Escondida Mine in Chile,

and we secure approximately 150,000 tons of copper concentrates annually from these mines. While mining development has

a long history, many easily accessible mining locations have already been exploited, resulting in the challenge of

increasing production costs for mines. Moreover, there is a shortage of supply for rare metals like cobalt, despite the

growing demand for them.

To address these concerns, Mitsubishi Materials has set a target of increasing the volume of secured copper concentrate

from the current 150,000 tons to over 500,000 tons by FY2030. This will be achieved through participation in new

medium-scale copper mines and other measures. This target represents approximately 30% of the copper concentrate volume

processed at the Naoshima and Onahama Smelters and Refineries.

in which Mitsubishi Materials holds interests

Recovering scarce resources with

the power of technological

development

We solve resource challenges through the power of technological development. In 2020, Mitsubishi Materials established

the Mining & Metallurgy Laboratories, expanding its existing smelting technology development base to include resource

technology development functions. We are strengthening technological development to ensure superior and stable

procurement of clean copper concentrates.

One of the challenges faced by existing operational mines is the decrease in ore grade (metal content) due to deeper

mining and the increasing impurities within copper concentrates. In response, Mitsubishi Materials has bolstered its

resource technologies through developments such as impurity removal techniques. This has enabled the establishment of a

comprehensive development framework that spans from metallic mineral analysis to metal recycling technologies, allowing

Mitsubishi Materials to swiftly tackle diverse technological challenges related to metallic minerals.

Securing resources

through recycling

Strengthen recovery of metal resources

through recycling technology

Mitsubishi Materials strives to become a leading and innovative player in the recycling of non-ferrous metal resources.

By strengthening our processing capabilities for recyclable items, including non-ferrous metals beyond E-Scrap, and

leveraging our world-class electrolytic copper supply capacity, we aim to become a core supplier within the resource

recycling ecosystem.

One of our strengths is the Material Grid, which consists of copper, precious metals, lead, and tin smelters. Through

enhanced collaboration along this value chain, focusing on non-ferrous metals, we will expand our presence in the realm

of resource recycling. Additionally, by driving innovative process development, we aim to enhance the efficiency of

resource recycling, thereby swiftly bolstering our competitiveness and expanding our business.

We are also focusing on discarded lithium-ion batteries (LIBs). With the increasing adoption of xEVs in society, the

quantity of LIBs used is expected to increase several tens-fold by 2030. Therefore, Mitsubishi Materials is working on

the early development of an integrated recycling process from LIBs to battery materials, as well as the collection of

black mass* by leveraging our E-Scrap network.

Within our FY2031 Strategy, the establishment of a domestic recycling center is positioned as a key initiative. This

center will serve as a central hub for consolidating and processing dismantled components from home appliances and

automobiles, ensuring appropriate recycling procedures. Through the expansion of processing capabilities for various

recyclable items, we aim to accelerate the recycling of metal resources.

*Concentrated lithium, nickel, and cobalt slag obtained by discharging, drying, crushing, and sorting LIBs.