- Home

- Products & Business

- Monozukuri and R&D

Monozukuri and R&D

Constantly Taking on Challenges of Technological Innovation Deriving from Our Materials Technologies

The Mitsubishi Materials Group aims to contribute to people, society and the Earth through application of its unique technologies. We aim to create products and technologies that distinguish our Group and enable us to win out in the global materials market, as well as propelling us forward to become a leading corporate group.

About Monozukuri* and R&D

In order to realize an end-to-end process from idea creation and research and development to mass production and commercialization,

Integrated departments related to manufacturing (production technology), development, marketing, and new business

Established a new Monozukuri and R&D Strategy Department

*"Monozukuri" is a Japanese term that describes the manufacturing of products that are superior in all aspects, including quality, cost competitiveness and delivery.MMC Group aims to enhance its production technology based on robust plant operations that enable continuous improvement of its "Monozukuri" competence.

Mission of Monozukuri and R&D Strategy Div.

To strengthen the business competitiveness and the new business creations of the Mitsubishi Materials Group

We will build a strong R&D infrastructure that is trusted by customers of a global standard and become an organization that can complete everything from R&D to mass production (commercialization).

We will promote the sophistication of our production process, the classification of manufacturing, and the development of smart factories.

We will create an organization by gathering talented human resources from all over the world to create ideas, products, and businesses that contribute to the growth of the Mitsubishi Materials Group.

We will promote the formation and utilization of strategic intellectual property in order to maximize the value of intangible assets.

Goals and Strategies of Monozukuri and R&D Strategy Div.

Goals:

We will achieve sustainable improvement in corporate value through the creation of new businesses, specialization of manufacturing, and maintenance and development of key technologies.

And we will contribute to the expansion of resource recycling and the strengthening of the supply of high-performance materials and products, which are our business opportunities defined in FY2031 Strategy.

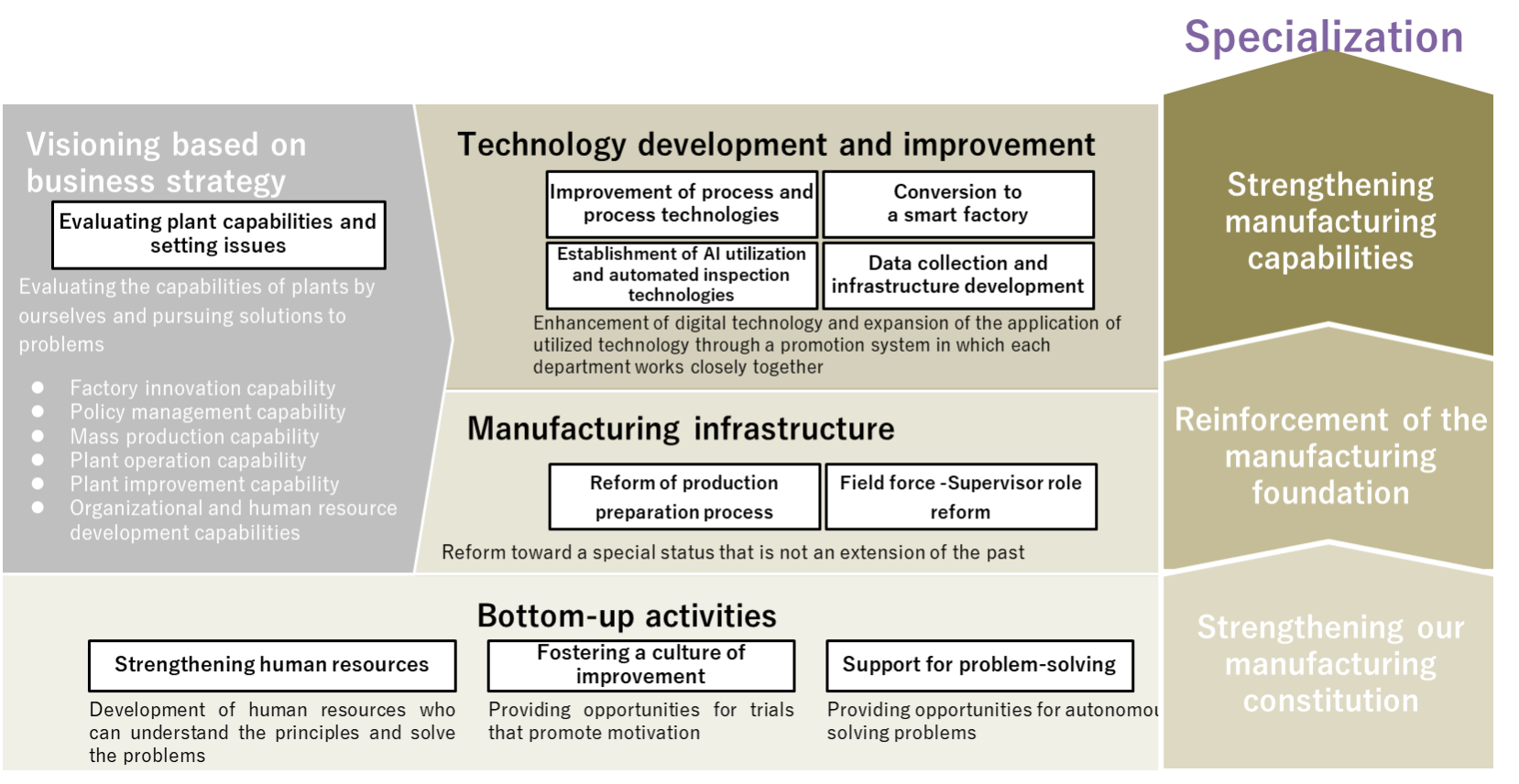

Manufacturing Strategy:

Establishing each factory vision based on FY2031 Strategy, evaluating plant capabilities, and pursuing problem-setting and resolution

"Differentiation of manufacturing capabilities" through bottom-up activities, enhancement of manufacturing infrastructure, and technological development and improvement

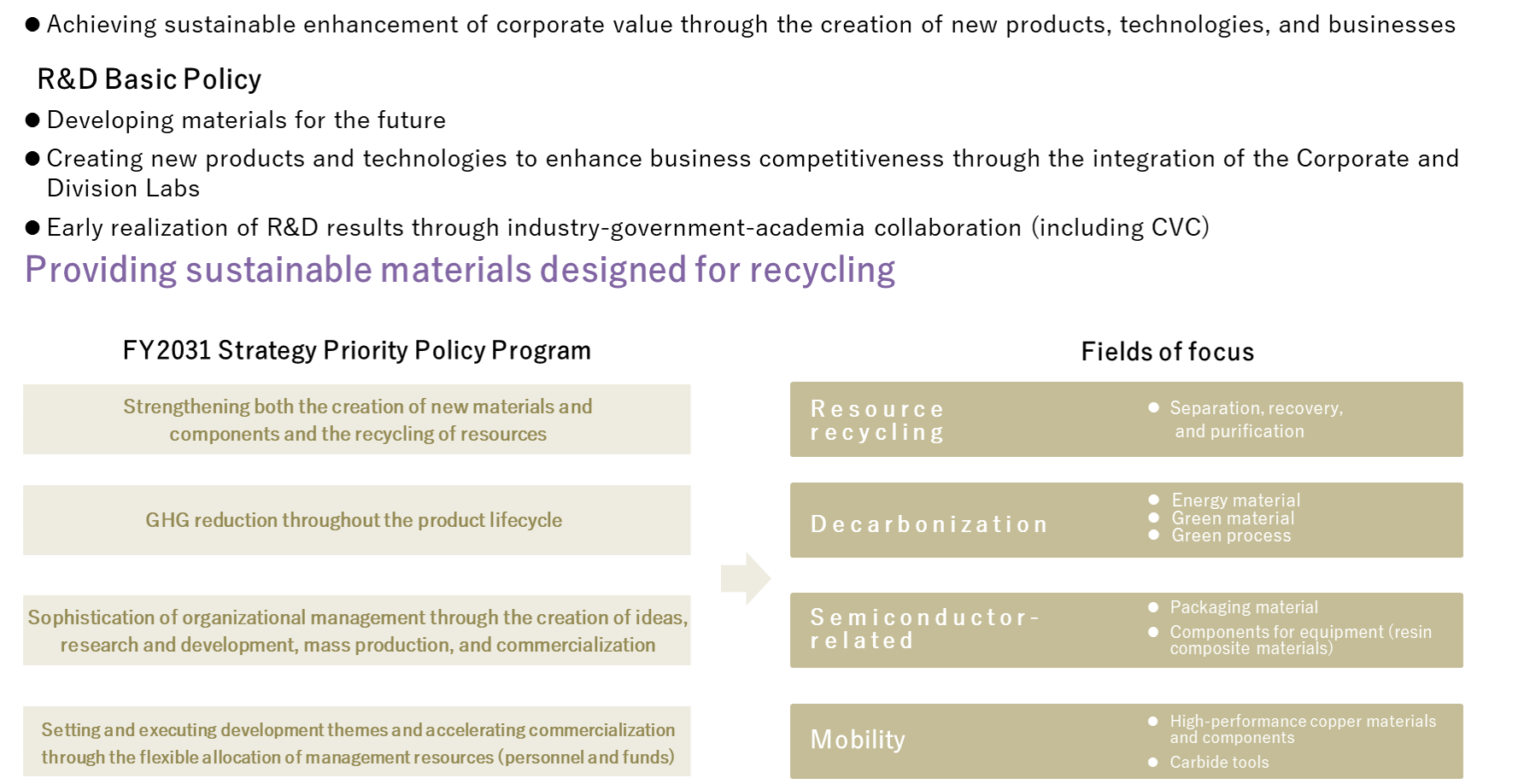

R&D Strategy:

Achieving sustainable enhancement of corporate value through the creation of new products, technologies, and businesses

Topics

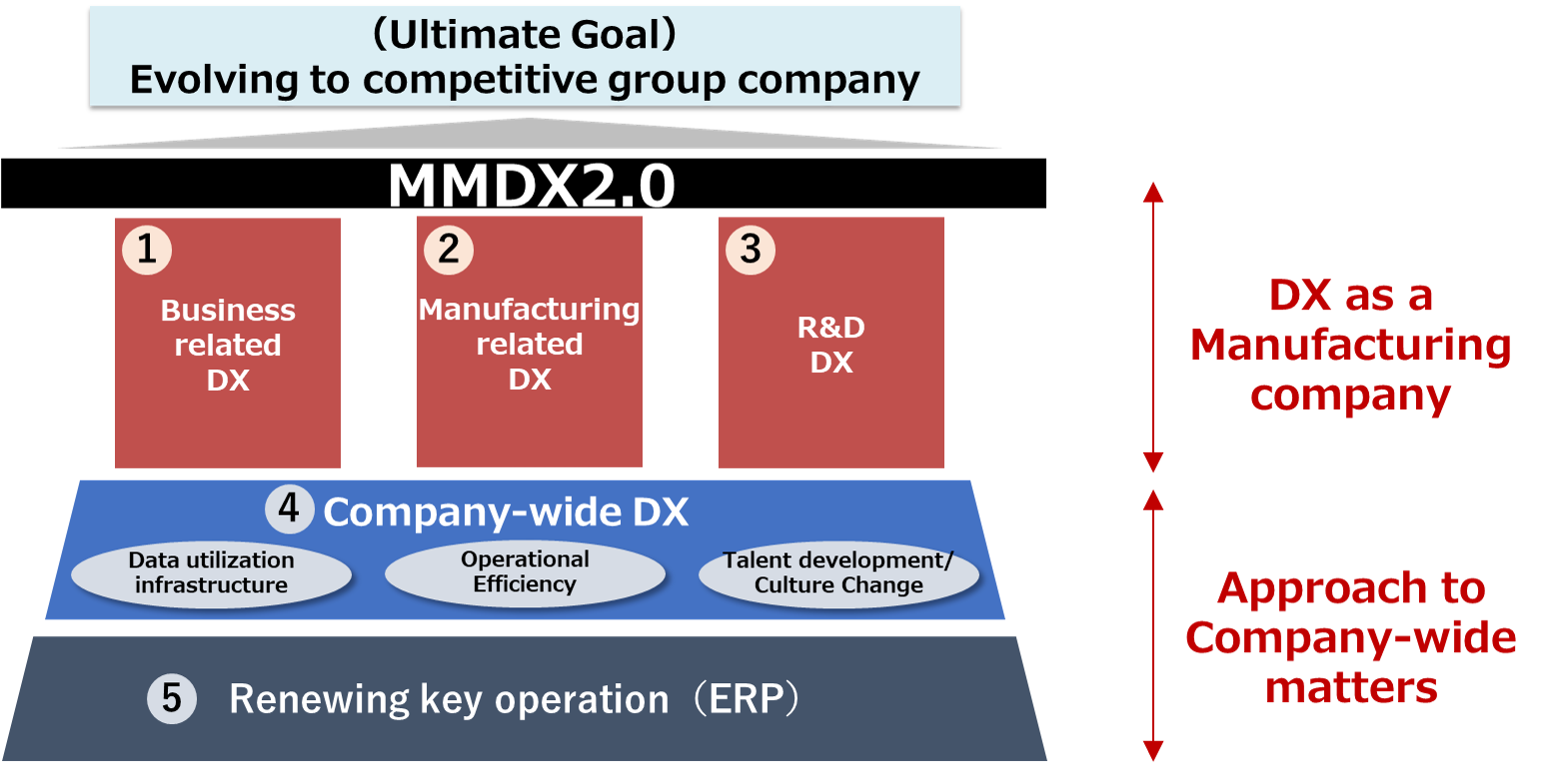

MMDX Company-wide Digitization Strategy Moves to the New "MMDX 2.0" Stage

- Aiming to Accelerate DX in the Manufacturing Field -

Mitsubishi Materials Corporation, with the aim of further advancing and deepening its Mitsubishi Materials Digital Business Transformation (MMDX) digitization strategy in progress since 2020, has decided to carry out a new phase of activities as "MMDX 2.0" from the second half of this fiscal year.

With MMDX up to now, we have been working on a variety of themes as part of the company-wide digital strategy for improving "Business added-value," "Business operations competitiveness," and "Management speed." As a result, we are beginning to see results for some themes, and one example is the start of operation of the new "MEX" platform for the E-Scrap business(*1).

(*1) Press release dated November 10, 2021 '"MEX," a New Platform for the E-Scrap Business, Starts Operation'

URL:https://www.mmc.co.jp/corporate/en/news/2021/news20211110.html

To further accelerate the promotion of DX in the manufacturing field and integrate it with the smart factory and other measures that we have been working on up to now and to steadily implement existing themes, we have decided to move into a new phase under the name "MMDX 2.0" by taking steps such as reorganizing the themes and strengthening the system. Through "MMDX 2.0," we will achieve management reform and implement various initiatives for realizing our ideal form with the aim of evolving into a competitive corporate group.

Mitsubishi Materials and Tokyo Institute of Technology established

Mitsubishi Materials Sustainability Innovation Collaborative Research Cluster

Mitsubishi Materials Corporation (CEO: Naoki Ono, hereinafter "Mitsubishi Materials") and the National University Corporation Tokyo Institute of Technology (President: Kazuya Masu, hereinafter "Tokyo Institute of Technology") have established the Mitsubishi Materials Sustainability Innovation Collaborative Research Cluster with the support of the Tokyo Institute of Technology Open Innovation Platform to conduct research on innovative materials and processes that contribute to a sustainable society.

The Collaborative Research Cluster will conduct joint research on composite materials, next-generation batteries, CO2 utilization and so on by combining the extensive and advanced knowledge of materials possessed by Tokyo Institute of Technology with Mitsubishi Materials' accumulated materials technology and know-how on recycling and other processes relating to non-ferrous metals, particularly copper. By leveraging the strengths of the two organizations to address issues that would have been difficult to address in independent research, the Collaborative Research Cluster aims to create innovative materials and processes, etc. based on the keyword Green Transformation (GX), which contributes to a sustainable society.

Mitsubishi Materials and Tokyo Institute of Technology will utilize this Collaborative Research Cluster to promote technological development while actively incorporating cutting-edge technologies and contribute to the building of a prosperous society.

Award in 2022

Awarded 56th Journal Prize by Japan Institute of Copper

Title:Mechanism of Modification of Strength/Stress-Relaxation Properties Induced by Low Temperature Annealing in Solid-Solution Copper Alloys

The research focuses on the stress relaxation phenomenon (heat resistance under thermal loading) in Cu-Mg solid solution alloys, and combines state-of-the-art X-ray diffraction line profile analysis with EBSD analysis to investigate the microstructural changes that cause the phenomenon to clarify its mechanism.

Cu-Mg solid solution alloys are a strength of Mitsubishi Material. The results of this research provides new material design strategies for copper-based solid solution alloys with superior strength/stress relaxation property balance than ever before.

Awarding of the Japan Fine Ceramics Association's Prize

Title:Development of sintering silver paste for pressureless bonding to copper substrates

This research is a bonding technology that utilizes fine ceramics technology (bonding of semiconductor devices to substrates for power modules), and is expected to contribute greatly to energy conservation, such as increasing the cruising range of electric vehicles.

Specifically, by understanding the bonding mechanism and optimizing the paste components, direct bonding to Cu substrates can be achieved without pressure, and has the potential to realize high performance power modules at low cost.

Based on the above, this technology was recognized as a new technology that will contribute to the development of the fine ceramics industry.

History

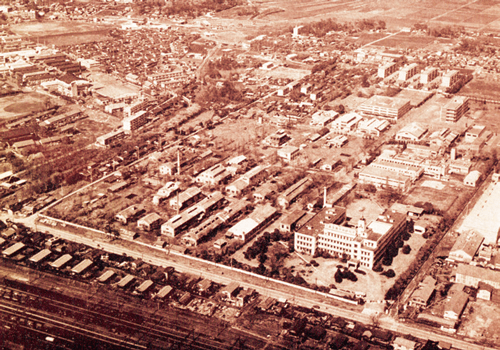

Mining Research Institute (At its start)

Mining Research Institute (At its start)

Mining Research Institute

Mining Research Institute

(At the time of moved to Omiya)

In 1917, Mitsubishi Goshi Kaisha established the predecessor to today's Innovation Center. Named the Mining Research Institute, this was Japan's first civilian research institute.

In 1939, the institute relocated to the city of Omiya, Saitama Prefecture. One of Japan's most preeminent research institutions for nearly a century, the Central Research Institute has engaged in research and development centered on materials and processes. Fields of application are diverse, including resources, energy, raw materials, basic materials, new materials, various types of products and even recycling. The institute generates synergies by making connections among these genres.

In 2001, we commemorated the dawning of a new century by constructing a new research wing in the city of Naka, Ibaraki Prefecture, and began a transition process that was completed in 2007. This year marked the relaunch of the Central Research Institute, operating branches in three regions: Onahama, Kitamoto and Omiya.

The name was changed from the Central Research Institute to the Innovation Center on April 1, 2022 in order to promote research and development and strengthening of manufacturing capabilities.

| 1917 | Established in Shinagawa, Tokyo, as the Mining Research Institute |

|---|---|

| 1939 | Relocated to the city of Omiya, Saitama Prefecture (now Omiya-ku, Saitama) |

| 1964 | Expanded fields of research, changed name to Central Research Institute |

| 1967 | Visited by the Showa Emperor and Empress |

| 1995 | Conducted organizational restructuring, changed name to the Sogo Kenkyujo |

| 2001 | Established the Omiya Research Center and the Naka Research Center within the Sogo Kenkyujo |

| 2007 | Conducted organizational restructuring, changed name to the Central Research Institute |

| 2022 | Conducted organizational restructuring, changed name to the Innovation Center |

Monozukuri and R&D Review

No1.2022 Special Feature: Next Generation Vehicles

Monozukuri and R&D Review No1.2022 Cover Page

Monozukuri and R&D Review No1.2022 Cover Page

Special Feature: Next Generation Vehicles

- cBN Tools and Wear Mechanism in the Turning of Hardend Steel

- Development of Substrates for Power Modules with Suitable Material Properties

- Sintering Copper Paste for Power Device

- Development of Corrosion Protective Plating for Copper Terminal to Prevent Galvanic Corrosion of Aluminum Wire Harness

- Influence of Precipitates and Strain on Solder Heat Resistance of Cu-Fe-P Alloy

- Developments of Electro-Deposition Insulation Technology with a High Temperature Durability for Next Generation Vehicles