News

June 19, 2017

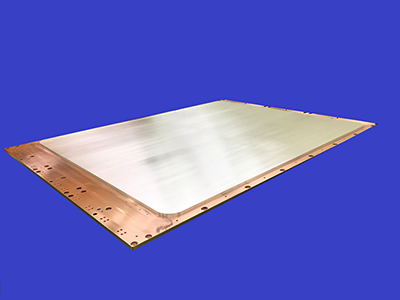

DIASILVER 201-100 New Silver Alloy Sputtering Target for Organic EL Displays Developed and Put Into Mass Production

The Electronic Materials & Components Company of Mitsubishi Materials Corporation (president: Akira Takeuchi, capital: 119.4 billion yen; hereinafter "MMC") has developed and commenced the mass production of DIASILVER 201-100, a new Silver alloy sputtering target for organic EL displays. In line with this recent development, MMC is launching the DIASILVER series, a new brand of Silver alloy sputtering targets, and is aggressively pursuing its market expansion.

A sputtering target is an electronic material used in deposition for alloy, metallic oxide and other substances, on an atomic level, to form a thin film on a substrate. Since silver has the characteristics of high reflectivity and low electrical resistance, Silver alloy sputtering targets are used to form reflective film, electrode film, wiring film or semi-transparent film (semi-translucent film).

MMC's Silver alloy sputtering targets for organic EL displays have enhanced the luminance and longevity of displays through characteristics including high reflectivity, excellent durability, low electrical resistance and high manufacturing technology. As a consequence, we have achieved market share of more than 90% (MMC's estimation) for many years and have remained the industry standard.

The recently-developed DIASILVER 201-100 has the following characteristics and effects. In addition to organic EL displays, its use will be extended to flexible displays, LCDs and other applications.

[Characteristics]

- 1 )

- The average grain size of the new target material is 100μm or less with a finer metal composition.

The average grain size of the existing product is 400μm or less. - 2 )

- Corresponds to seamless large-sized Silver alloy targets.*

(Plate) Integrated type G6, Division type G11, (Cylindrical) G8.5 - 3 )

- Fine uniformity of metal composition over the entire target.

Grain size variations through the thickness and along the target to be less than 20%.

[Effects]

- 1 )

- The fine uniformity of the film properties (electric and reflectance properties) within the thin-film substrate formed in the large substrate improves the quality of the images on organic EL displays.

- 2 )

- The reduction of abnormal discharge within the sputter device (arc discharge) and splash (scattering of target materials) improves the production yield of organic EL displays.

- 3 )

- The enlargement of the sputtering target extends the application of the product.

MMC has the following vision: We will become the leading business group committed to creating a sustainable world through materials innovation, with use of our unique and distinctive technologies, for People, Society and the Earth. MMC will continue to develop and offer unique and high value-added products by anticipating the needs of the market.

- *

- As the glass substrate (mother glass) for the manufacture of flat panel displays becomes larger in area, it is described as 1st generation, 2nd generation and so on. G6 is 6th generation mother glass of 1,500 mm × 1,800 mm; G8.5 is 8.5th generation mother glass of 2,200 mm × 2,500 mm; and G11 is 11th generation mother glass of 2,940 mm × 3,370 mm. The sputtering target needs to be larger than the mother glass.