News

April 14, 2016

Completion of Second E-Scrap Center at Naoshima Smelter and Refinery

--Creating world's top-ranked E-Scrap receiving and processing capacity--

The Mitsubishi Materials Corporation (President: Akira Takeuchi; Capital: 119.4 billion yen) announced today that its Metals company completed the second E-Scrap center at the Naoshima Smelter and Refinery on Tuesday, April 12. As a result of enhancements of E-Scrap receiving, sampling, analyzing and processing equipment, the combined E-Scrap receiving and processing capacity of Naoshima Smelter and Refinery and Onahama Smelting and Refining Co., Ltd., which is a member of the Mitsubishi Materials Group, is now approximately 140,000 tons per year (an annual increase of around 30,000 tons over current capacity), is ranked top in the world.

At the completion ceremony held on April 12, the Naoshima Smelter and Refinery welcomed around 50 guests from Kagawa Prefecture and Naoshima Town, and as the attendees looked on, the sampling equipment was started and full-scale operation began.

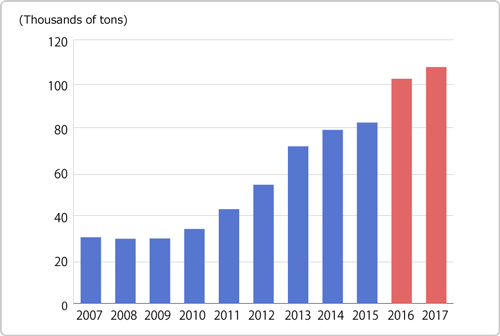

Taking advantage of the Mitsubishi Process for continuous copper smelting*, a unique technology for smelting precious metals with the lowest environmental impact in the industry, the Naoshima Smelter and Refinery has been promoting the expansion of E-Scrap receiving and processing from several years before, expanding E-Scrap processing capacity to around 80,000 tons per year in the fiscal year ended March 31, 2015 compared to approximately 30,000 tons per year in the fiscal year ended March 31, 2011. This latest investment of around 5 billion yen has increased capacity to around 110,000 tons per year.

The E-Scrap that Mitsubishi Materials receives and processes is mainly discarded circuit boards from various electronic devices that contain a high concentration of gold, silver, copper, palladium and other valuable metals. Amid growing environmental concerns, the amount of E-Scrap recovered is expanding globally, and we will continue to seek further expansion of processing capacity in the future.

Under Mitsubishi Materials Group's corporate philosophy of "For People, Society and the Earth," we aim to become "the world's leading business group committed to supporting recycling-oriented society through materials innovation, with use of our unique and distinctive technologies," as part of our long-term management policies focused on the early 2020's. The Metals company will continue to contribute to the development of a sustainable society through the collection and recycling of E-Scrap in accordance with these policies.

Note: Mitsubishi Process for continuous copper smelting

In this process, smelting furnaces, slag cleaning furnaces and converting furnaces are connected by enclosed launders, continuously producing blister copper from concentrates. This results in a facility that is compact, conserves energy and operates at a low cost.

The Mitsubishi Process prevents sulfurous acid gas leaks, creating zero-emission processing plants with non-polluting systems that process efficiently unlike conventional processes, in which movement between the furnaces results in the unavoidable leak of sulfurous acid gas.

(For reference)

Press release issued at start of construction

http://www.mmc.co.jp/corporate/ja/news/press/2015/15-0625.html