News

September 2, 2013

Development of MNEX®, the World's First Cu-Zn Alloy with Superior Stress Relaxation Resistance

Mitsubishi Materials Corporation (Hiroshi Yao, President and Chief Executive Officer; Paid-in Capital: ¥119.4 billion) has joined with consolidated subsidiary Mitsubishi Shindoh Co., Ltd. (Kazumasa Hori, President; Paid-in Capital: ¥8.7 billion) to develop the world's first Cu-Zn alloy (alloy composition: Cu-Zn-Sn-Ni-Fe-P) with superior stress relaxation resistance.*1

Automotive electronics have become increasingly complex in recent years, with the development of multifunctional, sophisticated onboard electronic devices and equipment creating an increasing need for smaller, highly-functional terminal connectors. Specifically, onboard terminal connectors must offer a high level of dependability by providing secure male-female terminal connections that retain interlocking holding force even in high temperature environments*2 for reliable signal relay. This called for a copper alloy with superior stress relaxation resistance, as well as an alloy with a high cost-performance ratio to minimize metal price volatility risk and cost of parts procurement.

Up to now, high-grade, high-priced Corson alloy (Cu-Ni-Si alloy) has been used for onboard terminal connectors due to its strength and formability, but Mitsubishi Materials Corporation (MMC) has now developed MNEX®, a new, quality-optimized copper alloy that reduces costs while providing the strength and formability that customers require.

MNEX® has strength and formability equal to Corson alloy (Cu-Ni-Si alloy), and besides being suited to the miniaturization of onboard terminal connectors, as a Cu-Zn alloy MNEX® offers superior stress relaxation resistance. Also, in addition to being produced through commonly used production processes, MNEX® reduces material costs by using 10% less high-priced copper and nickel by weight than Corson alloy as well as by using low-priced zinc, making it the world's first Cu-Zn alloy capable of reducing metal price volatility risk.

MMC foresees a broad range of applications for MNEX®, from low-priced automobiles for emerging countries to next-generation eco-cars. MMC will continue to proceed with the development and manufacture of optimal quality products that satisfy our customers.

*1...Spring-based stress relaxation resistance and interlocking holding force

Stress relaxation resistance is an indicator of the weakening of the spring force when load is applied within its elasticity range (where spring force is exhibited, 80% load of 0.2% proof strength) after heating at 150ºC for 1000 hours.

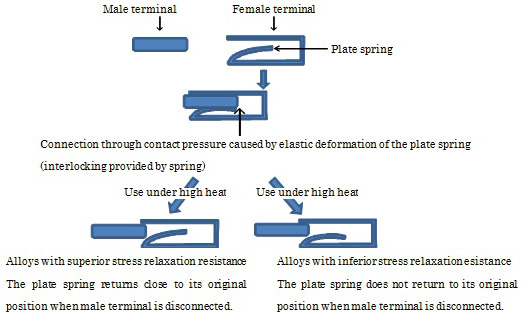

As shown in Diagram 1, alloys with superior stress relaxation resistance do not lose spring force after heat is applied, retaining the spring force of the area where the male and female terminals make contact and maintaining sufficient interlocking holding force. In contrast, alloys with inferior stress relaxation resistance show weaker spring force after heat is applied, reducing the interlocking holding force provided by the spring force in the male and female terminal contact area. Under such circumstances, vibration or similar effects may cause the male and female terminals to separate.

Diagram 1: Relationship between the interlocking of terminals and stress relaxation resistance

Diagram 1: Relationship between the interlocking of terminals and stress relaxation resistance

*※2...Interlocking holding force

The force required to maintain connection between the male and female terminals, depending on measurements. In the case of the terminals shown in Diagram 1, the female terminal interlocks to the male terminal through spring force of the plate spring.

Diagram 2 (A) Examples of male terminals

Diagram 2 (A) Examples of male terminals

(B) Examples of female terminals

(B) Examples of female terminals